Reliable Wood Plastic Composite

Manufacturer/Supplier

EcoxPlank is backed by the Chinese government and makes sustainable wood plastic composites for global infrastructure.

We also offer OEM and ODM services for international brands.

Welcome to Ecoxplank

EcoxPlank is a leading manufacturer of high performance Wood Plastic Composite (WPC) products in China. Our factory is located in Heze, Shandong Province, China. Covers an area of 45,000 square meters.

Our products include composite decking, composite cladding, composite fencing, composite railing and other application scenarios. The raw materials of all composite products are recyclable.

Focus on 25 years of technology inheritance and innovation, developed with original ecological wood, outdoor high weather resistance, high steel and high strength, creep resistance and warping, low shrinkage and low deformation, flame retardant and smoke suppression of low-carbon, energy-saving, green, industrial, prefabricated new building materials.

Products have strong wear resistance, anti-fouling, anti-mildew and other properties, and can achieve almost zero maintenance during 30 years of use. We always follow the popular patterns and colors in the market, so that our composite products continue to iterate.

EcoxPlank has participated in numerous projects worldwide, has been certified by international environmental organizations, and has worked with more than 20 countries and regions around the world.

Our Products

Check out our 200+ range of WPC decking sizes and specifications.

Any customized needs for your project can be met directly here, as well as factory-direct wholesale prices.

You can get free samples as well as a competitive price list

Wholesale Custom WPC Decking Board

Our WPC composite is available in 8 colors, regardless of thickness, length, panel color, texture can be customized.

Charcoal

Light grey

Grey

Chocolate

Red wood

Wood

Cedar

Coffee

WPC Decking Board Factory Wholesale Price

- Minimum Order Quantity: 300㎡ per design & color

- WPC decking board price: 12.5 – 32.9USD/SQM

- Any thickness, length, surface texture, color, wear resistance can be customized

Realize your project with any customized interior or exterior WPC composite approach

Let our digital manufacturing SOP process work for you

Supporting mature supply chain system

We have the largest composite material production base in China. The complete upstream and downstream industrial chain allows us to quickly produce and customize any required materials for you, and provide you with WPC with a very low industrial base advantage. goods

Instant quotation

Just tell us the WPC product, specifications, and quantity you selected, and the ECOX team can provide you with feedback on the best price and delivery time for the project within 30 minutes, without spending days.

Quality Assurance

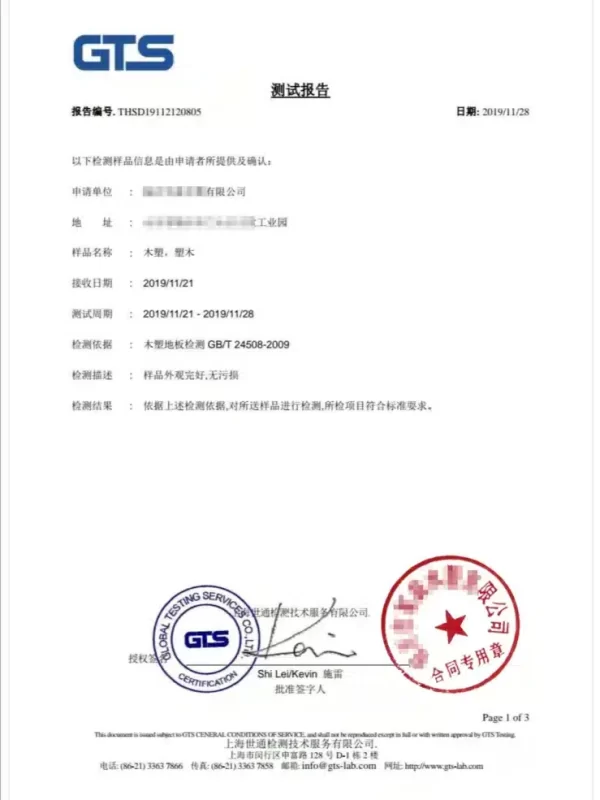

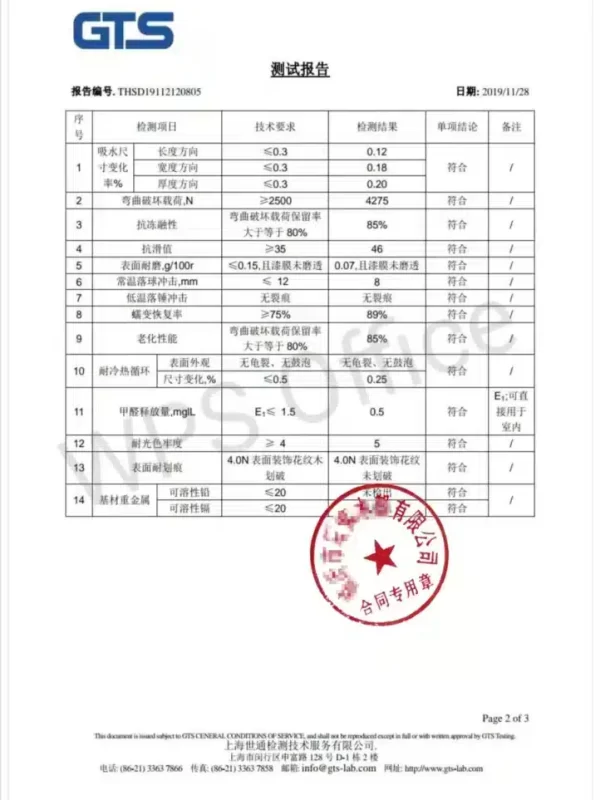

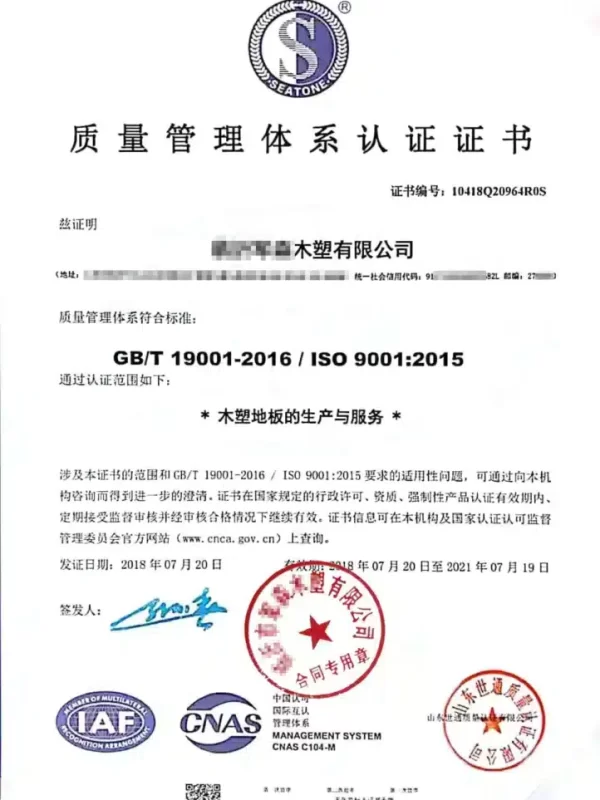

We have passed extensive international certifications such as ISO 9001:2015, ISO 13485:2016 and AS9100D. Learn more about our quality assurance.

Industry experience

Our new WPC composite material applications are very suitable for extreme scenes such as gardens, villas, outdoors, and indoors, with a service life of more than 25 years. We provide material certification, surface treatment certification, inspection reports and environmental certification.

Be All-Inclusive

With a wide range of WPCs, EcoxPlank can work with any type of customer, as shown below.

For Contractors and Subcontractors

When you are building or forming a WPC decor project, you need a specific solution for the project’s requirements. EcoxPlank can provide full service support for all your orders as well as a system maintenance schedule.

Ecoxplank has the customized solutions and world-class services you need for any industry, including construction, design firms and outdoor engineering. We have accumulated many years of experience in providing performance-focused WPC products for practical applications, durable, easy to install, low maintenance, regardless of extreme environment, high temperature, high strength, high humidity, fire resistance and other conditions, and we have large-scale project experience in several countries. Make sure our Wood plastic composites product solutions meet your project requirements.

For OEM/ODM Clients

To provide the right WPC product solution for all your customers, you need to meet their needs in a variety of industrial application scenarios. Working with Ecoxplank, you can provide any customer with a wide selection of WPC products, including WPC decking, WPC wall panels, WPC deck tiles, composite pergolas,WPC wall cladding, composite fencing, decking balustrades, composite planter boxes, composite benches, etc. You can also order customized solutions for specific projects.

With our WPC one-stop shop and full range of customization options, and our global project experience, Ecoxplank has the solution you need for your business. Working with us, you will have a qualified and experienced team and access to adequate raw material inventory, automated production, quality assurance and fast delivery times.

What Our Valuable Partners Say About Us

WPC and wood plastic material production solutions

Ecox has developed the world’s original continuous fiber-reinforced wood-plastic material, which greatly improves the tensile strength and bending strength of the material. The bending strength is increased by 50%, and the product shrinks by less than five ten thousandths.

Ecox has strong competitiveness in terms of high strength, flame retardant, environmental protection, weather resistance and waterproofing. We provide competitive prices and delivery times in terms of flexible & mass customization services, infrastructure gardening, outdoor and indoor project solution services, design and customization services, after-sales follow-up services, shipping services, and quality assurance services. Get started with a quote today, or contact us to get started.

In 2023, we recycled and used 8,536 tons of plastic waste. That’s the equivalent of 2.82 billion bottle caps!

Free Sample Packs

We very much hope that customers can order our samples so that you can truly experience the texture and color of our composite materials, and the delicate touch will further confirm that this is what you want.

Once we receive your request, it will be sent within 2 days. Each sample pack will come with the style and corresponding accessories of your choice.

Ready to Get a Quote?

Take advantage of our network and see what Ecox can do for you.

Ecox Go Green Initiative

ECOX is committed to promoting environmental sustainability in our services. We work with the China Climate and Environment Association, an organization that matches businesses with carbon offset programs including reforestation, renewable energy, capturing harmful gases, and more.

We participate in Alibaba’s Ant Forest program and provide 1% of profits every year as funds for the green plan. These funds will be used to reduce or offset emissions in the manufacturing process and carry out sustainable environmental development plans.

Reflect usage scenarios and case endorsements

EcoxPlank collaborates globally with leading design teams and construction firms to create impressive projects for clients. In diverse architectural spaces, we have employed co-extruded composite decking, solid and hollow wall cladding, composite timber tubes, wall panels, ceilings, decorative trims, and various other composite WPC materials to meet spatial requirements. Our high cost-effectiveness solutions emphasize the durability, aesthetics, low cost, low maintenance, longevity, and installation systems of our materials.

WPC Outdoor Decking and Composite Wall Panels

Private home · South Korea

WPC Composite Fencing in Courtyard and Gate

Housing · Daegu, Korea

WPC Interior Decorative Timber Tube

Opera Museum Kunshan, China

Building facade WPC timber tube

Junshan Cultural Center, Beijing

WPC composite cladding, ceiling, facade decoration

Detached House · Siddo Arho, Indonesia

Composite Timber Tube is Used to Decorate the Large Ceiling

INTERCONTINENTAL· ShenZhen

WPC Wall Cladding for the Building

Suzuki Daichi Memorial Hall · Japan

WPC flame retardant and deformation resistant Timber Tube

2016 Rio Stadium

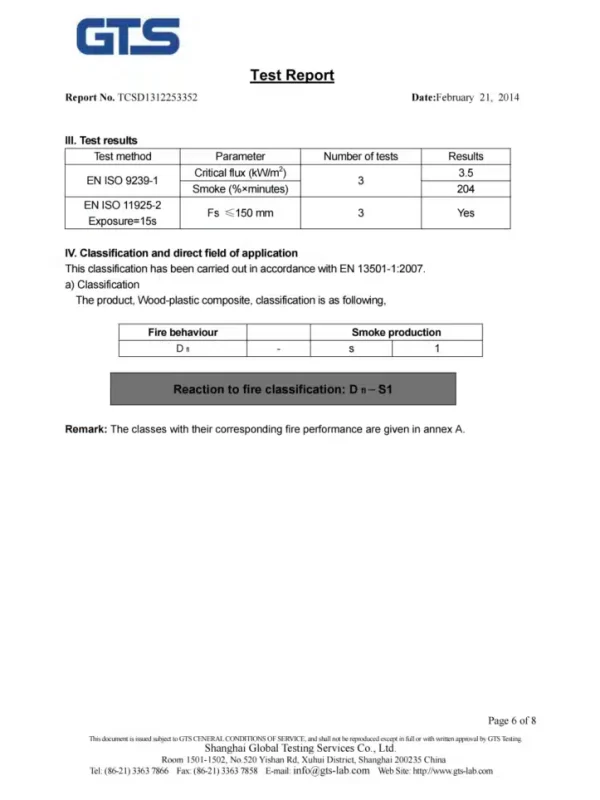

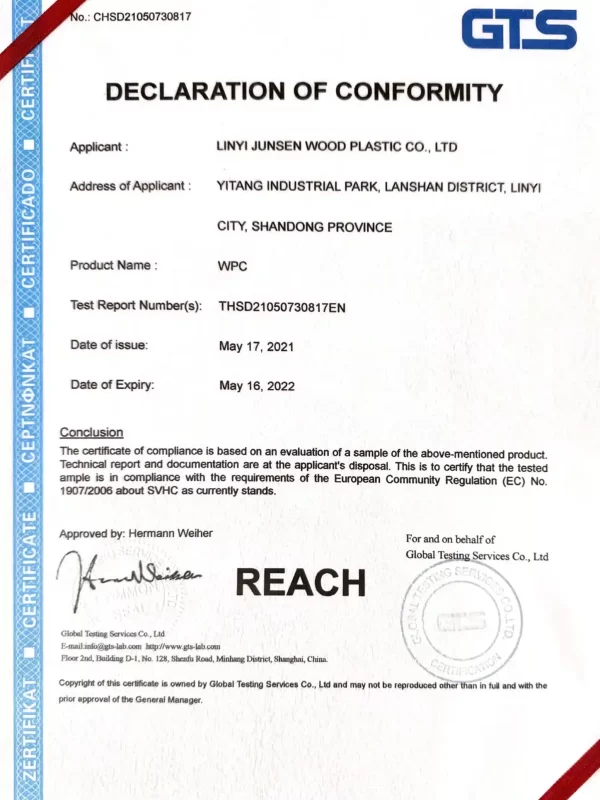

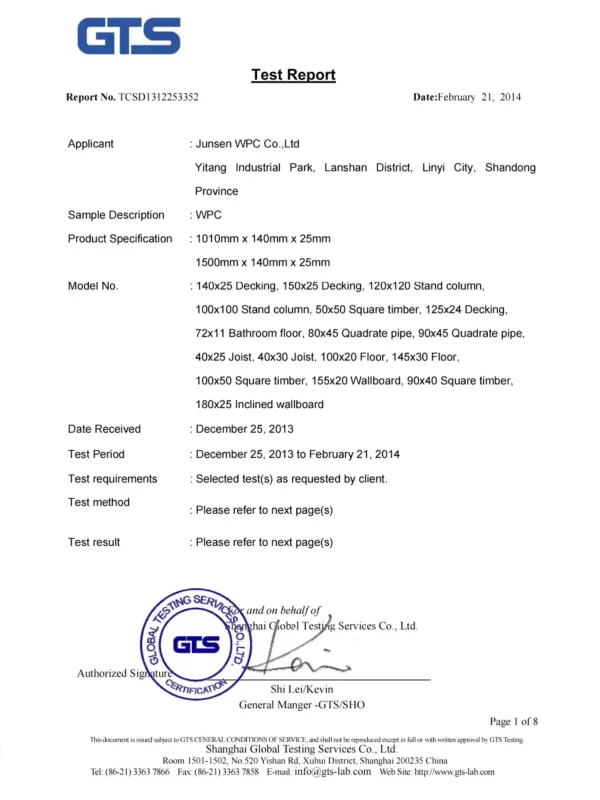

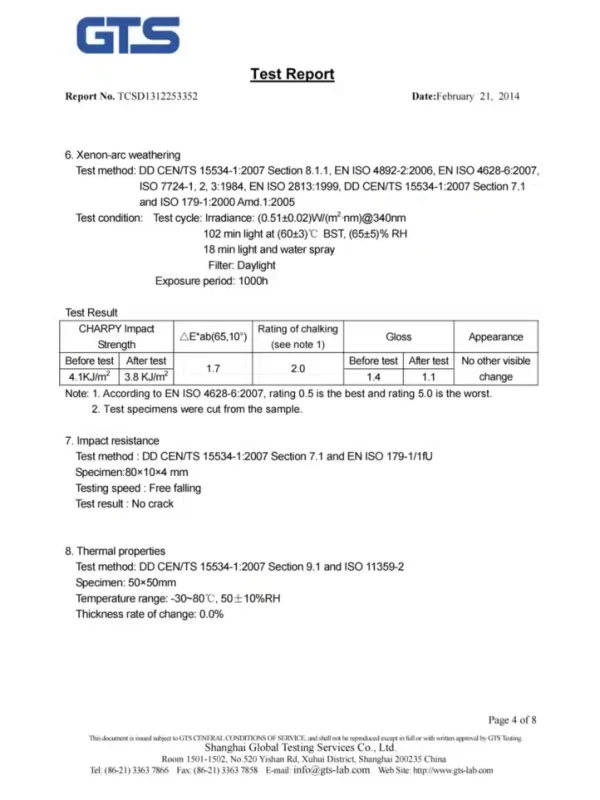

Authoritatively Certified

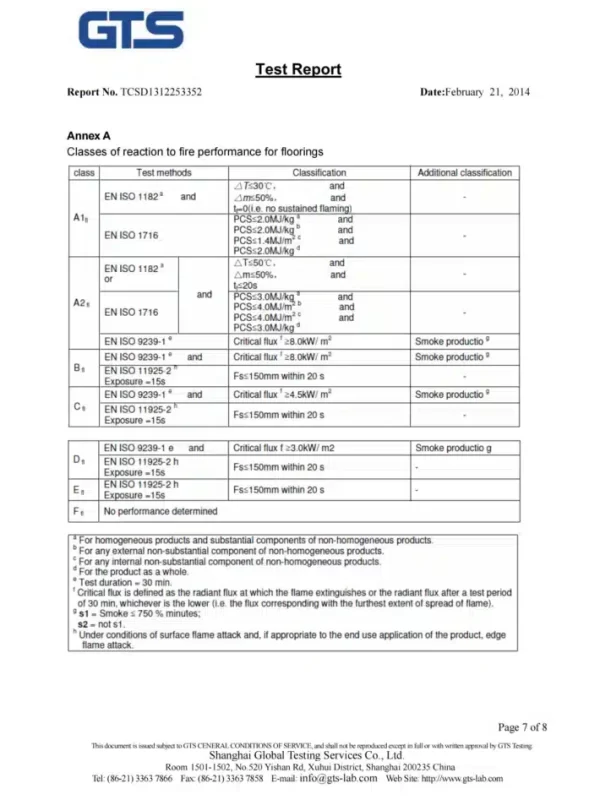

As our factory complies with ISO quality management requirements, EcoxPlank’s products are made following SGS,CE, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.

How We Handle Details Makes Us Different

We use fully automated programs to control every detail in the production of WPC and other composite materials. From WPC wood powder mixing, granulation, extrusion, texturing, sanding, embossing, to packaging, we follow standardized procedures. This ensures that our WPC products have top-notch physical performance and stability.

WPC wood grain automatic laminating

Advanced automatic veneer technology to give WPC products a natural and beautiful wood grain effect, and avoid uneven veneer quality.

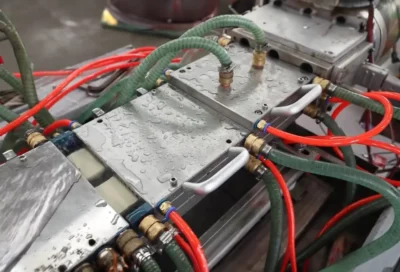

wood plastic composite extrusion hot and cold molding

wood plastic composite automatic temperature control

Precise temperature control at every stage of the WPC production process ensures that wood plastic composites products avoid quality problems caused by temperature fluctuations.

Wood plastic composite automatic trimming film

The use of automatic blanking film technology to ensure the stability of the edge of the product, while improving the weather resistance and service life of the product.

Automatic wpc particle transport co-extrusion system

Efficient and stable production with fully automated particle handling and WPC co-extrusion systems ensures complete unity of WPC performance and quality.

Automatic Control System of WPC Composite High Speed Mixing Unit

Precise control of the WPC formulation and mixing process to meet specific requirements such as composite structure, water resistance, fire resistance, etc.

WPC raw powder mixing system

The efficient mixing system ensures the uniform mixing of raw materials and avoids defects such as composite material density, force and sunken structural defects

WPC automatic co-extrusion system

Can efficiently produce a variety of Composite products, can customize any WPC product size, specifications, textures, etc