Everything You Need to Know About WPC Wall Panels: A Complete Guide

Table of Contents

ToggleIn today’s green, eco-friendly, and sustainable building materials market, WPC (Wood-Plastic Composite) Wall Panels have gained popularity for their unique advantages, becoming a new favorite for both residential and commercial spaces.

This guide will provide a complete overview of WPC wall panels, including their definition, materials, types, manufacturing process, pros and cons, applications, installation tips, maintenance, and how they compare to traditional wood and PVC.

We will also explore price considerations, market trends, and future developments to help you choose the right WPC wall panel for your needs.

What is A WPC Wall Panel?

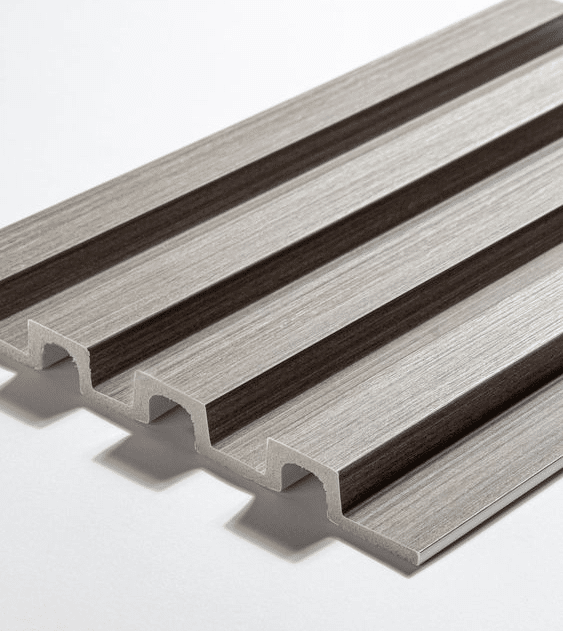

WPC Wall Panels are a high-tech, eco-friendly material made by combining natural wood fibers (like timber cellulose) with thermoplastic polymers (such as high-density polyethylene) and additives. The mixture is then processed using molds and heat extrusion. WPC wall panels combine the benefits of both wood and plastic, offering an ideal alternative to traditional materials.

These panels are lightweight, heat-insulating, moisture-resistant, fire-retardant, and easy to install. Without the need for painting, they reduce harmful chemicals like formaldehyde and benzene, making them more environmentally friendly. Due to their hollow core structure, they save on material costs, making them affordable.

In summary, WPC wall panels are eco-friendly, durable, and attractive building materials that are increasingly popular in the market.

WPC Wall Panel Material Composition

- Wood-Based Materials The main components are timber cellulose and plant fibers. These provide the panels with a natural wood-like texture and appearance.

- Thermoplastic Polymers Typically, high-density polyethylene (HDPE) and polyvinyl chloride (PVC) are used. These materials enhance the physical properties and processability of the panels.

- Additives Fillers, plasticizers, stabilizers, and other additives are included in the manufacturing process to improve processing and product stability.

Ecoplank WPC Wall Panel Type

The 1st Generation WPC Wall Panel

Structure:

- Simple construction, primarily composed of plastic and wood powder.

- There is no obvious structural distinction between the inner and outer layers.

Physical Properties:

- Average performance, no protective layer.

- The performance of anti-aging, wear resistance, dirt resistance, and other aspects is average.

Appearance: Basic, with limited color options.

Applications: Suitable for low-performance requirements.

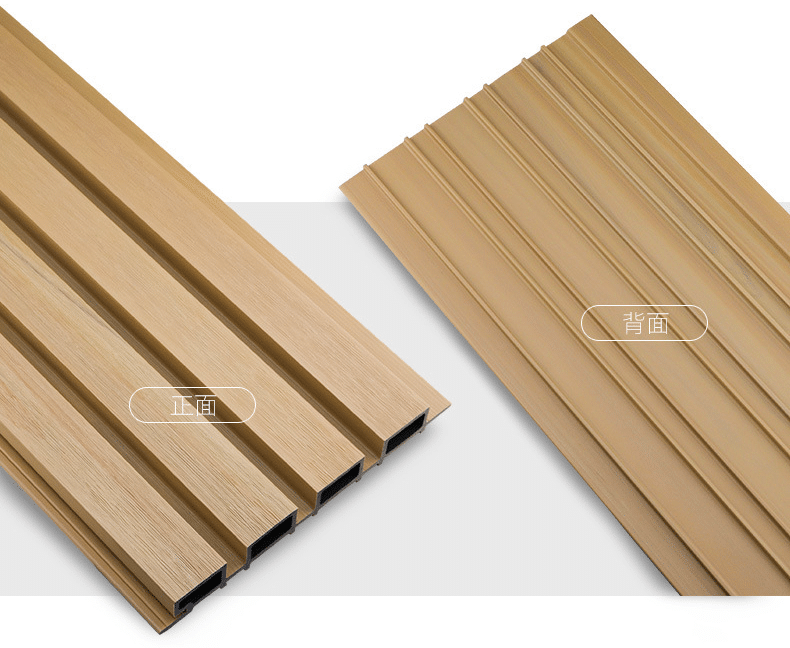

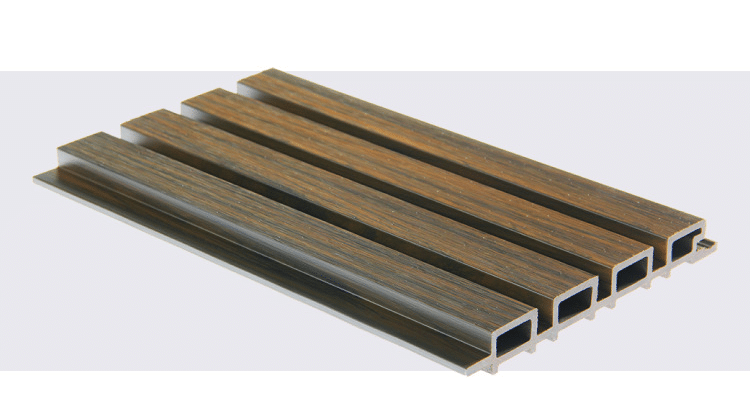

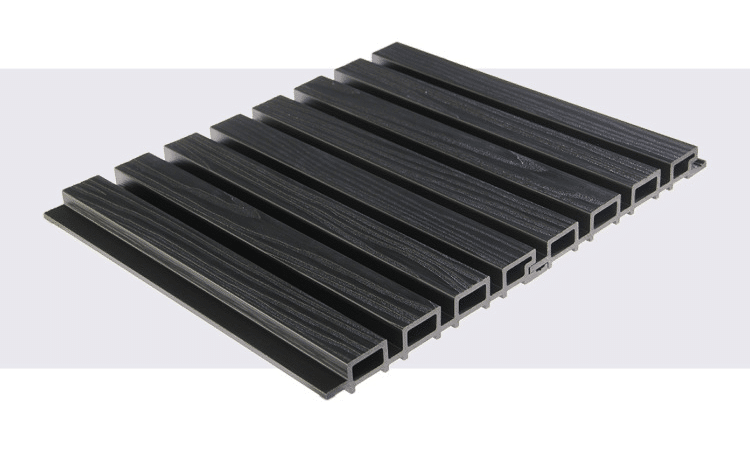

The 2nd Generation Co-Extruded WPC Wall Panel

Structure:

- Two-layer construction with a core of wood powder and plastic, and an outer HDPE layer.

Physical Properties:

- Higher hardness and durability.

- The inner layer of the tree substrate provides strength and stability.

- The outer polymer coating layer increases the weathering resistance of the product.

- Excellent anti-mildew, anti-insect, wear resistance, scratch resistance, dirt resistance and other properties.

Appearance: More natural wood-like texture with multiple color options.

Applications: Ideal for high-traffic areas like parks, gardens, and public spaces.

Manufacturing Process of WPC Wall Panels

Material Preparation and Pre-treatment

- Select and measure the wood powder and thermoplastic polymers.

- Pre-treat materials by crushing and sieving the wood powder.

Mixing and Extrusion

- Melt the polymers and mix them with wood powder.

- Extrude the mixture into panels using molds.

Cooling and Solidifying

- Panels are cooled using water or air to solidify the shape.

Cutting and Quality Inspection

- Panels are cut to the desired size and undergo quality checks.

Features of WPC Wall Panels

- Waterproof and Moisture-Resistant

- Features: It completely solves the problem of wood products being prone to rot and deformation in humid environments.

- Reasons for Preference: Ideal for high-humidity areas such as bathrooms and kitchens, it eliminates the common issues with traditional wood products in these environments, enhancing the durability and applicability of the materials.

- Insect and Ant Prevention

- Features: Effectively prevents insect infestation, significantly enhancing the product’s lifespan.

- Reasons for Preference: Reduces maintenance and replacement costs caused by insect damage, extending the lifespan of wall panels, especially suitable for outdoor or insect-prone environments.

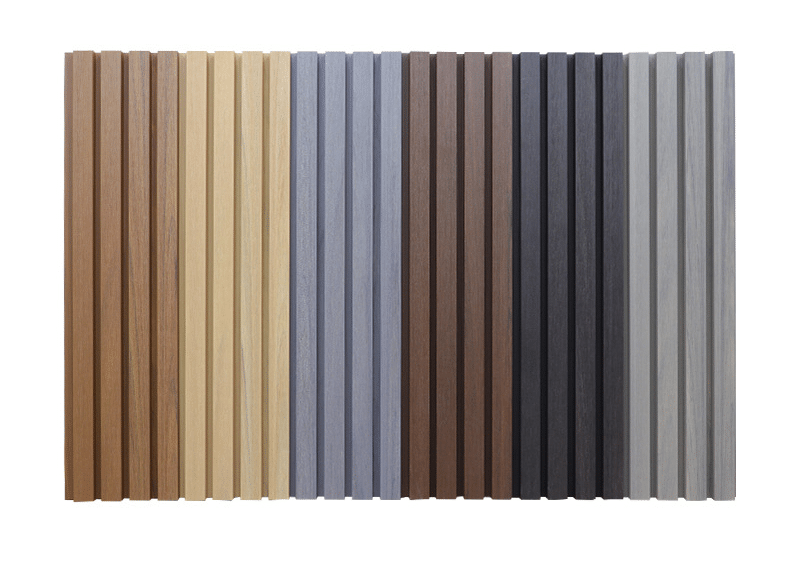

- Rich in Colors

- Features: Offers a variety of color options, with natural wood texture and grain, supporting personalized customization.

- Reasons for Preference: Meets diverse design styles and individual preferences, enhancing indoor aesthetics and overall design appeal.

- Highly moldable

- Features: Easy to achieve personalized shapes and designs.

- Reasons for Preference: Flexible to adapt to complex design and shaping needs, enhancing creativity and variety in decoration.

- Environmentally Friendly and Non-Polluting

- Feature: The product is free from benzene and has formaldehyde levels lower than the EO standard, is recyclable, and complies with European environmental standards, contributing to sustainable development.

- Reason for Selection: Meets modern demands for environmental protection and health, reducing environmental pollution and health risks during installation.

- High Fire Resistance

- Feature: Fire rating of B1, self-extinguishing when exposed to fire, and does not release toxic gases.

- Reason for Selection: Enhances building safety, and reduces fire hazards, especially in public spaces and residential areas.

- Easy Installation

- Feature: Quick and simple installation without complex processes, saving time and costs.

- Reason for Selection: Reduces installation difficulty and time, lowers installation costs, and improves installation efficiency.

- Low Maintenance

- Feature: The product is resistant to cracking, swelling, and deformation, requires no maintenance, is easy to clean, and reduces long-term maintenance costs.

- Reason for Selection: Cuts down on future maintenance costs and time, improving the durability and practicality of the wall panels.

- Soundproof and Energy-Saving

- Feature: Significant soundproofing effect, with indoor energy savings of over 30%, enhancing living comfort.

- Reason for Selection: Improves living comfort, reduces noise pollution and energy consumption, aligning with green building and energy-saving principles.

Drawbacks of WPC Wall Panels

Higher Initial cost

WPC panels are more expensive than traditional materials like wood or PVC, mainly due to high-quality raw materials and specialized manufacturing processes. However, from the perspective of long-term use and maintenance, the overall cost of WPC wallboard may not be too high, because it can save later maintenance costs.

Thermal Expansion WPC materials may expand or contract with extreme temperature fluctuations. Please choose Ecoxplank’s WPC with high thermal stability. Proper space should be left during installation to accommodate expansion.

Applications and Uses of WPC Wall Panels

Interior Decoration

Applications:

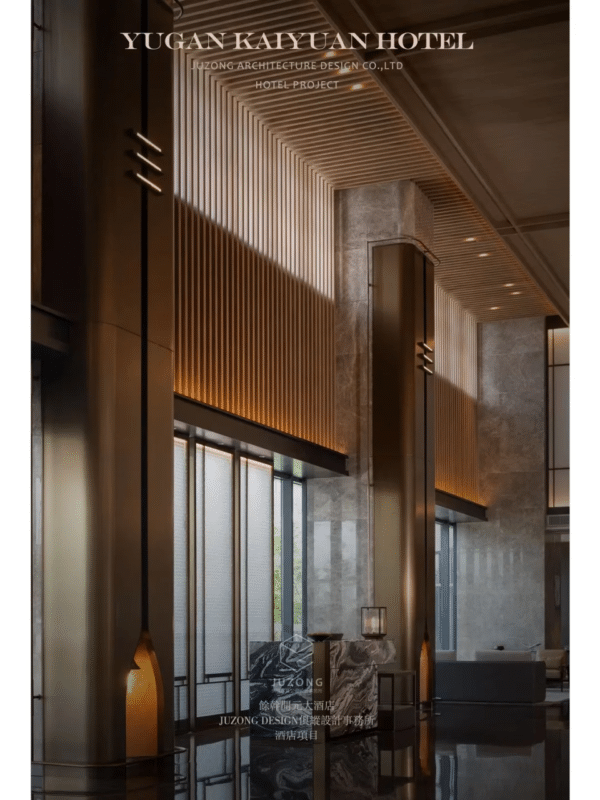

- Suitable for internal wall decoration of bedrooms, living rooms, offices, hotels, restaurants, and other indoor places to create a naturally warm and comfortable atmosphere.

Case Examples:

- In the interior decoration of some high-end homes, WPC wall panels are used as background walls, which are beautiful and elegant, and are integrated with simple decoration and furniture.

- In the office, WPC panels are used for interior partition walls, adding beauty and creating a comfortable, efficient working environment.

- In a modern bathroom, the designer wanted to meet waterproofing needs while improving the space’s aesthetics and comfort. Traditional tiles are waterproof but difficult to install, and their seams collect water, making cleaning harder. WPC wall panels are an ideal choice for both the ceiling and walls in the bathroom.

- In areas prone to grease and moisture, such as around the sink, stove, or cooking areas, WPC wall panels are an ideal choice for kitchen wall decoration due to their waterproof, oil-resistant, moisture-proof, and easy-to-clean features.

- In the hotel lobby design, the designer used WPC wall sheets to create a modern, upscale, and cozy atmosphere, enhancing the visual appeal and attracting guests. At the same time, the durable, eco-friendly, and low-maintenance features of the decorative wall panels perfectly meet these needs, supporting the hotel’s sustainability goals.

- A high-end art gallery used WPC wall panels as the backdrop for display walls, utilizing its diverse surfaces and colors to provide an excellent platform for showcasing modern art.

Outdoor Landscape Facilities

Applications:

- Terrace and deck: WPC wall panels are ideal for enclosing outdoor areas, providing privacy while enhancing the overall design of the terrace and deck.

- Exterior wall decoration: WPC wall panels, as a premium protective layer material for the exterior facades of commercial and residential buildings, not only enhance the overall appearance of the structure but also effectively resist wind and rain erosion, extending the building’s lifespan.

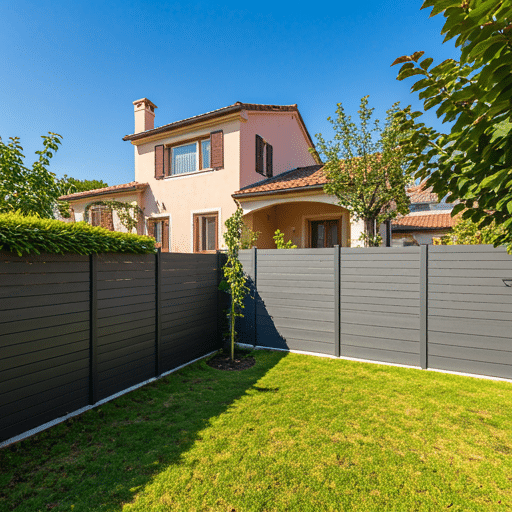

- Fencing and Boundary Walls: WPC wall panels can be used to create stylish and durable fences, enhancing the beauty of gardens and courtyards.

- Parks and Recreational Areas: WPC wall panels are ideal for public parks, providing seating areas, information kiosks, and weather-resistant decorative walls.

Case Examples:

- A coffee shop installed WPC panels for exterior walls in its outdoor dining area, creating a warm atmosphere while providing privacy and protection from the wind.

- WPC wall panels were used on the exterior facade of a shopping mall, offering durability and resistance to harsh weather and adding a stylish and modern touch to the mall.

- In a picturesque suburban neighborhood, a villa used WPC wall panels for fencing to divide the garden, enhancing both aesthetics and functionality, while resisting environmental wear and harmonizing with the villa’s design.

- A large park used WPC wall panels in its visitor center, offering durability and weather resistance to ensure stability and safety in harsh conditions. The panels’ varied colors and textures enhance the kiosk’s functionality and visual appeal.

- A residential terrace wall, previously affected by moisture and lacking privacy, was upgraded with WPC wall siding. This enhanced its appearance, blocked moisture and UV rays, and provided privacy, while the panels’ weather resistance ensured long-lasting durability.

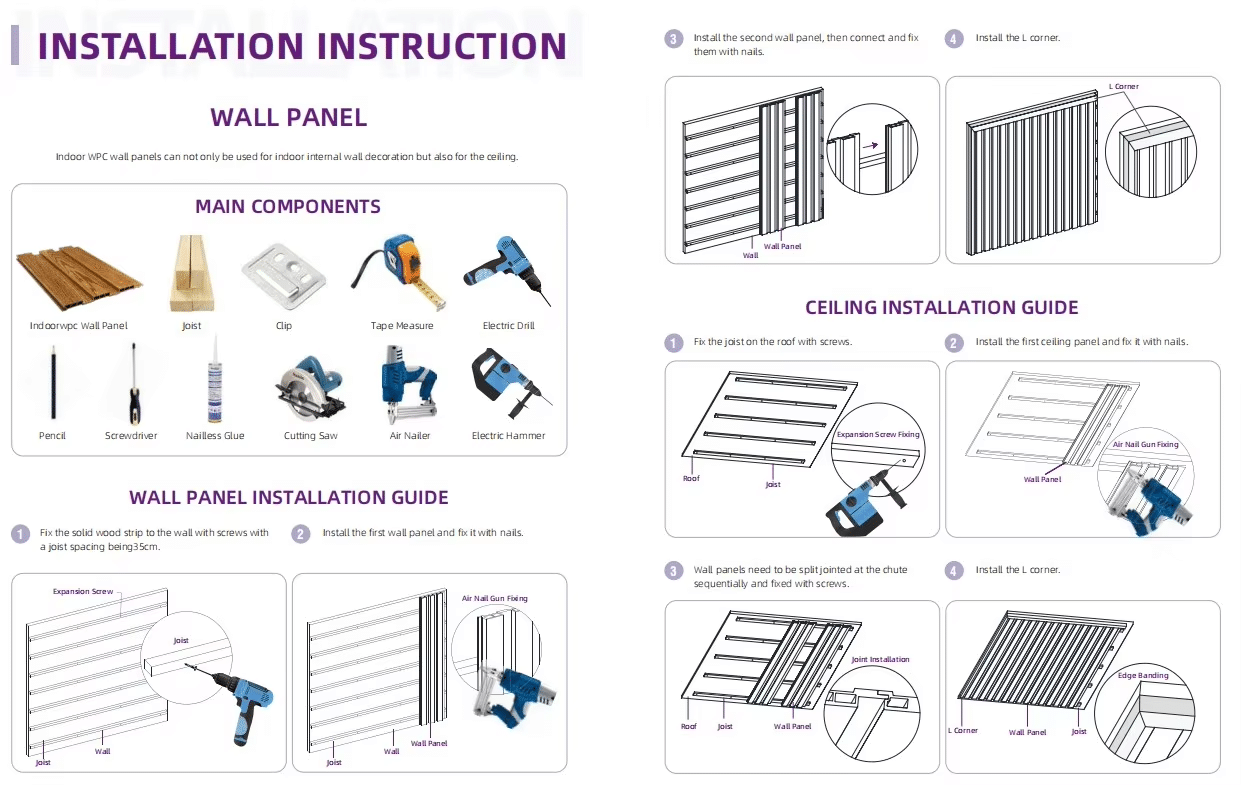

Installation Tips for WPC Wall Panels

Installation procedure:

Preparation: Ensure the wall surface is smooth and dry.

Substructure: Install a framework (batten) to support the panels.

Panel Fixing: Secure panels with screws, leaving space for expansion.

Joint treatment: The adhesive seals the joint and reserves the gap to prevent deformation.

Maintenance and Care of WPC Wall Panels

Cleaning: Wipe with a soft, damp cloth. Avoid harsh abrasives.

Ventilation: Ensure proper airflow in humid environments to prevent mold.

Impact Resistance: Protect from heavy impacts that could cause damage.

Fastener Check: Regularly inspect screws and fasteners. Tighten any loose ones to ensure safety and stability.

Comparison of WPC, traditional wood, and PVC boards

| Item | WPC Wall Panel | Wood Wall Panel | PVC Wall Panel |

| Material | Wood fiber+HDPE | Natural timber | Polyvinyl chloride plastic (PVC) |

| Environmental Protection | Crafted from recycled materials | Eco-friendly when sourced responsibly | May emit harmful substances during production |

| Weather resistance | Excellent waterproof, moisture-proof | Susceptible to moisture, decay | Good waterproof performance, resistant to moisture |

| Fireproof | Excellent fire resistance | Poor fire resistance, flammable | Provides some fire resistance, may release toxic fumes |

| Durability | Extremely strong, excellent durability | Poor | Excellent weather resistance, moderate durability |

| Service life | 30+ years | 10-20 years with good protection | 10-20 years |

| Maintenance | Easy maintenance, regular cleaning | Requires regular maintenance, treatment | Primarily dusting, avoid using harsh cleaners |

| Appearance | Wood-like appearance with various designs | Natural grain and color, but prone to warping | Smooth surface, but lacks natural texture |

| Ease of installation | Fast installation, relatively simple | Relatively complex, requires carpentry skills | Fast installation, can be fixed through adhesive |

| Cost | High initial cost, but low maintenance | Lower, but higher long-term maintenance cost | Low initial installation cost |

| Application | Suitable for indoor, outdoor applications | Ideal for indoor or high-end designs | Suitable for wet, seaside environments |

Price Considerations of WPC Wall Panels

- Raw Material Quality The quality of raw materials directly affects product cost and price. High-quality wood and eco-friendly plastics are more durable and visually appealing, leading to higher prices. The wood-to-plastic ratio in WPC panels also impacts price; higher wood content provides a better natural look and greater durability, which increases the cost. For example, EcoPlank’s WPC panels use a mix of 50% wood fiber, 38% plastic, and 12% additives for superior quality.

- Production Process Differences in production processes and technology also affect product price. Advanced techniques and equipment improve product quality and stability but raise production costs. Fine processes, like surface treatment and texture creation, enhance product appeal and beauty, thus increasing the price.

- Size and Thickness The size and thickness of WPC panels significantly influence their price. Larger panels generally cost more, and increased thickness improves load-bearing capacity, further raising the price.

- Market Demand and Brand WPC panel prices vary by brand due to differences in brand reputation, market demand, and marketing strategies. Well-known brands often charge higher prices due to guaranteed quality, excellent customer service, and extensive promotion.

- Installation Cost Using professional installation services adds to the overall cost, while DIY installation can save this expense if the individual has the necessary skills.

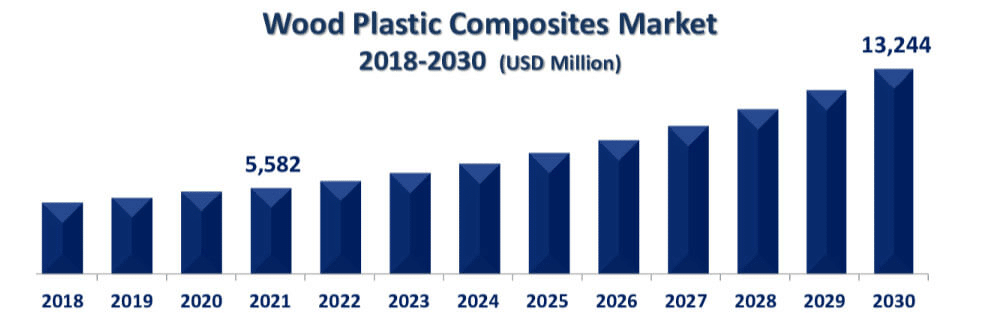

Market Trends and Future Outlook of WPC

Wood-plastic composite (WPC), as an innovative and environmentally friendly building material, is experiencing growing demand alongside the increasing awareness of environmental issues and the widespread adoption of sustainable development principles. As a result, their application and market presence are expected to continue expanding. Looking ahead, WPC panels are likely to be widely used in more diverse fields, further broadening their market boundaries.

- Growth in Demand As environmental awareness increases and the building materials industry undergoes profound changes, WPC panels are becoming increasingly popular due to their superior performance, eco-friendly attributes, and elegant appearance. As a quality alternative to wood and plastic, WPC panels are gaining the trust of consumers. Market forecasts suggest that the annual production of wood-plastic composite materials will exceed one million tons, signaling significant market growth.

- Product Upgrades With the advancement of Industry 4.0 and smart manufacturing, the WPC panel industry is gradually moving toward intelligent and automated production. By introducing advanced production equipment and automation systems, such as computer-aided design (CAD) and computer numerical control (CNC), personalized customization and precise production will be achieved. This will result in new, innovative, and competitive products that offer better performance and aesthetics while emphasizing sustainability and environmental protection.

- Diversified Application Fields Currently, WPC panels are widely used in residential, commercial, public facilities, and landscaping projects, meeting various decorative needs with their diverse specifications and excellent performance. In the future, their application is expected to extend to fields such as automotive interiors and furniture manufacturing. Smart production will further elevate their quality and efficiency.

- Environmental Policy Drivers Government support for renewable and eco-friendly materials is fostering the growth of the WPC panel industry. The trend of recycling waste materials is becoming a key driver in the wood-plastic composite market, bringing more opportunities and policy incentives to the industry.

Where to Buy High-Quality WPC Wall Panels?

When looking for high-quality WPC wall panels, EcoxPlank is a trusted supplier of high-quality WPC wall panels with 25 years of expertise. Our panels, made from original ecological wood, offer excellent weather resistance, strength, and durability, along with low shrinkage, creep resistance, and flame retardancy. They require almost no maintenance and last up to 30 years.

We stay ahead of trends with popular patterns and colors, and our products meet international environmental standards. EcoxPlank has worked on projects in over 20 countries, earning a strong reputation globally.

Contact us now for professional recommendations!

Get A Free Quote

Related Blog

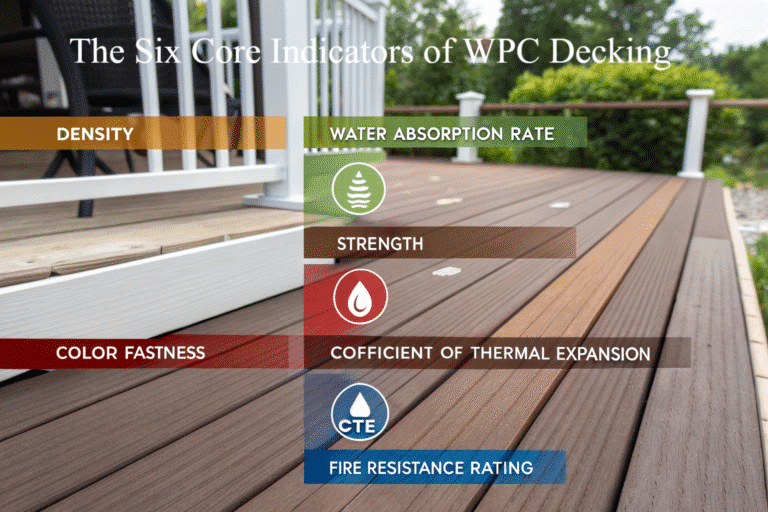

The 6 Most Important Technical Indicators of WPC Decking

When you approach the building materials market or browse e-commerce platforms, faced with hundreds or thousands of WPC decking (compos...

Should You Source WPC Fence from China?

If you are a wholesaler or project contractor, sourcing WPC fencing from China can help you cut costs significantly.

However, not all ...

Swimming Pool WPC Deck: Complete Manufacturer Guide

As a professional WPC composite decking manufacturer, we found that 90% of swimming pool projects face common issues.These include wate...

The 6 most popular WPC gate styles

As a WPC product manufacturer in China, we have collected numerous customer requirements for WPC fence gates from projects worldwide. W...

Load more posts

Loading...