Are WPC Wall Panels 100% Waterproof?

Strictly speaking, WPC wall panels are not 100% waterproof, but high-quality WPC wall panels have waterproof performance that comes very close to being completely waterproof.

Premium products typically have a water absorption rate of less than 1.5%, absorbing almost no water. This level of water resistance fully meets the usage requirements for most household humid environments, including bathrooms and kitchen areas.

In this article, we will take a comprehensive look at the waterproof performance of WPC wall panels. Our goal is to help you make the right choice when selecting waterproof materials.

Last updated: April 2025 | Estimated reading time: 7 minutes

- The real waterproof performance of WPC wall panels

- The waterproofing principle and scientific basis of WPC composite materials

- Actual water absorption test results

- How to identify high-quality waterproof WPC wall panels

- Comparative analysis of waterproof performance between WPC and PVC wall panels

What is the waterproofing principle of WPC wall panels?

The waterproof property of WPC wall panels mainly lies in the fact that this material is formed by high-temperature extrusion of wood fibers and thermoplastic plastics (usually polyethylene or polypropylene).

Form a tight molecular structure to effectively prevent water penetration.

Traditional wood is prone to absorbing water because its porous structure allows water to enter through capillary action. However, in WPC, the plastic components completely coat the wood fibers, forming a waterproof barrier.

This is like putting on a waterproof coat for the wood. Even in an environment that is exposed to moisture for a long time, the wood fibers inside can remain dry.

Technical Analysis of the Waterproofing Principle of WPC Wall Panels

During the production process of WPC wall panels, plastic and wood fibers are completely fused at high temperatures. The plastic melt penetrates into the tiny gaps of the wood fibers and forms a dense composite upon cooling.

This structure not only prevents moisture from seeping in but also endows the material with excellent dimensional stability.

| WPC Waterproof Performance Influencing Factors | Impact Level | Typical Values | Practical Significance for You |

|---|---|---|---|

| Wood powder to plastic ratio | High | 40:60 to 30:70 | Higher plastic ratio means better waterproofing but higher cost |

| Production temperature | Medium | 170-200°C | Better temperature control results in higher product density and more stable waterproofing |

| Additives types | Medium | 1-5% | Special waterproofing additives improve performance and extend service life |

| Surface treatment | High | Edge sealing + coating | Good edge treatment prevents water from penetrating through connections |

Practical tips and suggestions for You

- Installation in bathroom environment: Select WPC wall panels with a wood-plastic ratio not exceeding 40:60, and ensure that the edges are professionally edge-sealed.

- Kitchen usage scenario: Use WPC wall panels with waterproof coating to enhance resistance to oil stains and moisture.

- Outdoor wall application: Choose WPC wall panels with added UV stabilizers to prevent performance degradation caused by sunlight and rain

Actual case:

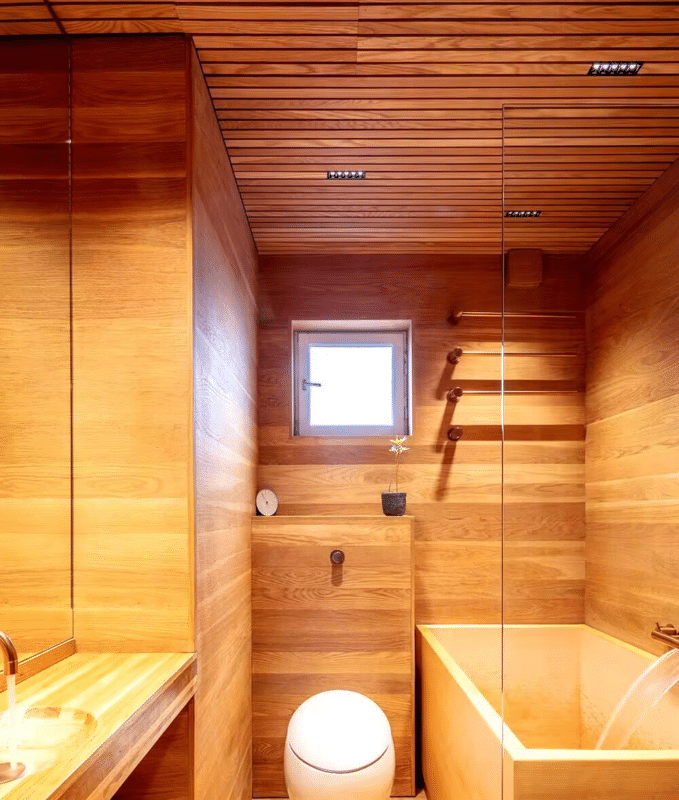

The bathroom renovation project of intercontinental Shenzhen Dameisha has been using high-quality WPC wall panels for more than five years.

Even in a high-temperature and high-humidity environment, the wall panels remain intact and undamaged, with no mold on the surface, which proves their outstanding long-term waterproof performance.

How is the water absorption performance of WPC wall panels?

Ecoxplank’s WPC wall panels typically have a water absorption rate below 2%, far superior to traditional wood’s 10-15% absorption rate. This means that even when you use them in humid environments for extended periods, WPC wall panels maintain their dimensional stability and surface aesthetics.

Under international standard test conditions (24-hour immersion), high-quality WPC wall panels show almost no noticeable expansion or deformation, making them an ideal choice for high-humidity areas such as bathrooms and kitchens. You can confidently use WPC wall panels in these areas without worrying about common wood problems like warping, cracking, or mold growth.

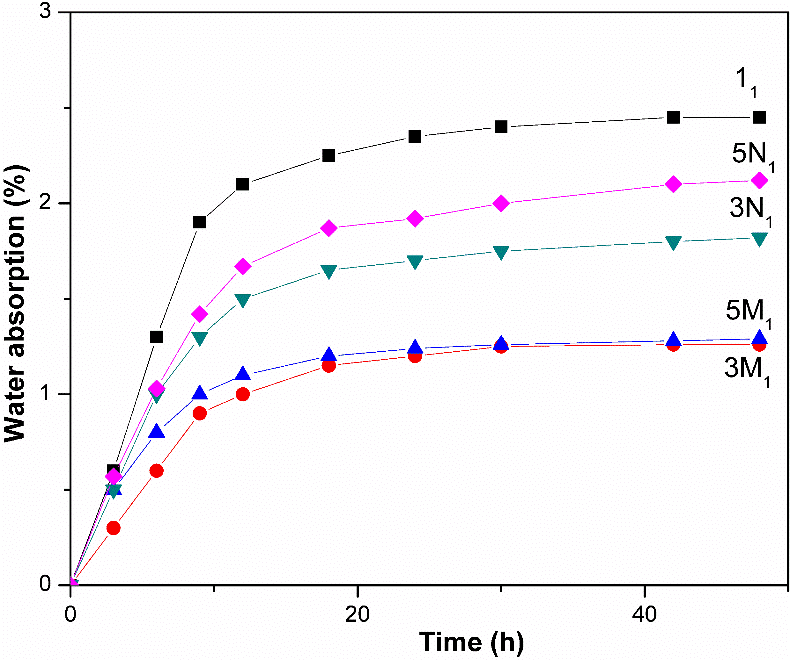

Analysis of standard water absorption test results

Different formulations and manufacturing processes of WPC wall panels show variations in water absorption performance. According to ISO 17064 standard testing, the 24-hour water absorption rates of WPC wall panels in the market perform as follows:

High-quality WPC wall panels: 0.5%-1.5%

Standard WPC wall panels: 1.5%-3%

Low-quality WPC wall panels: >3%

Reference: Traditional solid wood boards: 10%-15%

Reference: Ordinary plywood: 15%-30%

From these figures, it is evident that even low-quality WPC wall panels significantly outperform traditional wood-based materials in terms of water resistance, making this a key reason for choosing WPC products.

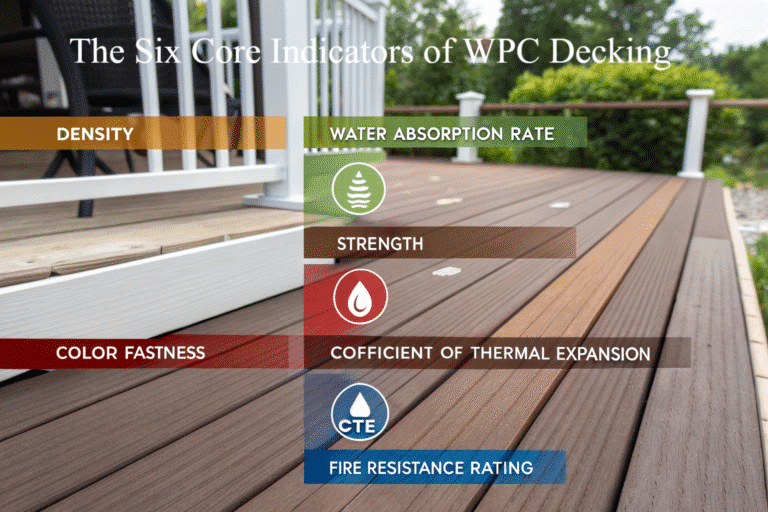

Key Factors Affecting the Water Absorption of WPC Wall Panels

The water absorption performance of WPC wall panels is influenced by a variety of factors. Understanding these factors can help you select the most suitable product:

- Wood fiber content: A higher proportion of wood components typically results in a higher water absorption rate.

- Density: High-density WPC (>0.95 g/cm³) exhibits significantly lower water absorption compared to low-density products.

- Additives: Specialized waterproof additives can reduce the water absorption rate by more than 50%.

- Manufacturing process: Hot-pressed manufacturing generally provides better water resistance than cold-pressed methods.

- Surface treatment: Professional coatings can further reduce the surface water absorption rate by nearly 80%.

WPC wall panels' performance when soaked in water

In long-term water immersion tests, high-quality WPC wall panels, even after being submerged continuously for 30 days, typically show a weight increase of no more than 5%, with dimensional changes controlled within 1%. This is far superior to traditional wooden wall panels, which may experience significant swelling, warping, or even structural damage under similar conditions.

This excellent water absorption performance makes WPC wall panels particularly suitable for installation in areas prone to leaks or water spills, such as bathrooms, laundry rooms, and kitchen sink areas.

For you, this means that even in the event of a sudden pipe rupture or water spill, the WPC wall panels will remain intact.

Comparison of water immersion tests for WPC wall panels of different qualities

The quality of WPC wall panels on the market varies greatly. The following is a comparison of the performance of different grades of products in the immersion test:

| WPC Model | Water Absorption After 7 Days Of Soaking | Water Absorption After 30 Days Of Soaking | Appearance Condition | Good Water Resistance Usage Period |

|---|---|---|---|---|

| High-Quality WPC | <2% | <0.5% | Almost no change | Can withstand long-term soaking, suitable for outdoor and new environments |

| Medium-Quality WPC | 2–4% | 0.5–1% | Slight swelling/pale color | Suitable for short-term soaking, not suitable for long-term water exposure |

| Low-Quality WPC | 4–8% | 1–3% | Obvious swelling/pale yellow | Only suitable for short-term water exposure, not suitable for outdoor use |

| Ordinary Wood | 15–25% | 4–8% | Severe swelling/deformation | Quickly absorbs water and deforms, not suitable for long-term water exposure |

How to choose waterproof WPC wall panels?

When choosing truly waterproof WPC wall panels, special attention should be paid to the product formula, process standards, manufacturer qualifications and third-party certifications. Not all WPC wall panels on the market that claim to be “waterproof” can offer the same level of performance.

When choosing waterproof WPC wall panels, you should ask the supplier to provide water absorption rate test reports and relevant certifications. Such as EN 13501(European Fire Protection Standard) and ASTM D7031(American Standard for Plastic-Wood Composites), these are reliable bases for evaluating the true performance of products.

Checklist for choosing waterproof WPC wall panels

- Check the water absorption rate data in the product specification sheet – high-quality products usually indicate a water absorption rate of less than 2% within 24 hours.

- Check the density value – high density (>0.95g/cm³) usually indicates better waterproof performance

Understanding the wood-plastic ratio – Products with plastic content ≥60% usually have better waterproof performance. - Check the edge treatment – The edges of high-quality WPC wall panels should be smooth and dense, without obvious pores

Confirm the surface treatment technology – products with an additional waterproof coating offer more comprehensive protection. - Check the installation system – Select a wall panel system with a waterproof connection design, such as a tongue groove structure.

- Samples are required for testing – immerse the samples in water for 24 hours and observe the changes.

Suggestions for choosing WPC wall panels for different application scenarios

The selection criteria for WPC wall panels also vary depending on different usage environments:

- Bathroom shower area: Choose high-end WPC wall panels with a water absorption rate of less than 1% and anti-mold additives

- Kitchen sink area: Use medium and high-density WPC wall panels with oil-resistant coating

- Laundry room: Choose WPC wall panels that are resistant to chemical erosion to avoid detergent damage

- Basement walls: Use WPC wall panels with anti-mold function to deal with possible moisture problems

- Outdoor walls: Choose UV-stabilized WPC wall panels specially designed for outdoor use, which have better weather resistance

Actual case:

A homeowner chose high-density WPC wall panels for the bathroom decoration. Two years later, due to water pipe leakage, the back of the wall panels was damp for a long time. However, when they were removed and inspected, it was found that the wall panels themselves were intact. Only the damp gypsum board on the back needed to be replaced, saving a lot of rework costs.

PVC vs. WPC fluted panel: Waterproof Performance Comparison

In strict waterproof performance tests, the water absorption rate of PVC wall panels is usually less than 0.1%, while the water absorption rate of the best WPC wall panels is approximately 0.5-1%. Although PVC has a slight edge in pure waterproofing, WPC wall panels have obvious advantages in comprehensive performance, environmental friendliness and texture.

For ordinary household use, the waterproof performance of WPC wall panels is already fully sufficient to cope with daily humidity and occasional contact with water. Only in environments where long-term direct contact with water or high humidity is required (such as public showers), the absolute water resistance of PVC becomes even more important.

Comprehensive comparative: WPC and PVC wall panels

The following table provides a detailed comparison of key performance indicators between WPC and PVC wall panels:

| Performance Metric | WPC Wallboard | PVC Board | Impact on Your Choice |

|---|---|---|---|

| Waterproof Performance | Excellent (Water absorption: 0.5–2%) | Exceptional (Water absorption: <0.1%) | PVC excels in extreme humidity; WPC sufficient for household use. |

| Aesthetic Texture | Natural wood-like feel | Artificial appearance | WPC offers premium decorative effects. |

| Eco-Friendliness & Health | Good (No heavy metals) | Average (May contain phthalates) | WPC better for health-conscious households. |

| Heat Resistance | Moderate (70–80°C) | Low (60–70°C) | WPC has lower deformation risk in high-temperature environments. |

| Impact Toughness | High (Resists cracking) | Medium (Brittle at low temps) | WPC withstands daily collisions and wear better. |

| Installation Flexibility | Saw-cut & nailable | Requires specialized adhesive | WPC allows flexible DIY installation. |

| Price Range | Medium-High | Medium-Low | PVC has lower upfront cost; WPC offers long-term value. |

Guide to Wall Panel selection for Different needs

Based on different needs and priorities, the suggestions for wall panel selection are as follows:

- Pursue absolute waterproofing: Choose PVC wall panels, especially in extreme environments such as commercial shower facilities.

- Emphasize aesthetic texture: Choose WPC wall panels to achieve a high-end feel closer to natural wood

Environmental and health considerations: Give priority to WPC wall panels, especially in children’s rooms and elderly living Spaces. - In cases of limited budget: Mid-range WPC or high-end PVC can be chosen to balance cost and performance.

- DIY installation requirements: WPC wall panels are more suitable for self-installation and can be installed with conventional woodworking tools

The latest development of WPC wall panel waterproofing technology in 2025

In 2025, the waterproofing technology of WPC wall panels witnessed a major breakthrough. The new generation of nano waterproofing technology reduced the water absorption rate of WPC wall panels to the lowest level in history (0.3%), approaching the absolute waterproofing performance of PVC while retaining all the advantages of WPC.

Chinese manufacturers have led this innovation by launching a variety of WPC wall panels with a “lotus leaf effect” surface treatment designed based on bionics principles.

Overview of the Latest Progress

- Nano waterproof technology: Through nano-scale waterproof coating treatment, a superhydrophobic layer is formed on the surface of the new WPC wall panel, with a water droplet contact Angle of more than 150°, achieving a self-cleaning effect.

- Application of bio-based plastics: Use bio-based plastics extracted from renewable resources such as corn and sugarcane to replace some petrochemical plastics, enhancing environmental performance while maintaining excellent water resistance.

- Digital texture technology: High-precision digital printing processes accurately replicate wood grain while forming a microscopic waterproof structure on the surface, balancing aesthetics and functionality

Market research shows that in 2025, the export volume of high-end waterproof WPC wall panels made in China increased by 32% year-on-year. The main reason is that its waterproof performance has approached that of PVC, while it has obvious advantages in other aspects.

At present, in high-end residential decoration projects in North America and Europe, the usage rate of WPC wall panels has exceeded the combined total of traditional wood boards and PVC boards for the first time, becoming the preferred material.

Can WPC wall panels be used in shower rooms?

Choose WPC wall panels specially designed for wet areas, ensure that waterproof sealant is used at the joints, and keep a small gap (about 5mm) between the bottom of the wall panel and the ground to prevent water accumulation.

Properly installed WPC wall panels can be used in a shower room for 5 to 10 years without replacement.

How does WPC wall panel waterproofing compare to ceramic tiles?

The grout between the tiles may deteriorate over time and cause water seepage, while modern WPC wall panel systems typically feature seamless or waterproof connection designs.

From the perspective of the overall waterproofing system, the waterproofing effect of the professionally installed WPC wall panel system is comparable to that of the tile system.

How to test the waterproof performance of WPC wall panel?

Products with a weight increase of no more than 1-2% have good waterproof performance. It is also possible to observe whether the sample shows obvious expansion, deformation or delamination. High-quality products should maintain their shape and appearance basically unchanged.

Will WPC wall panels mold after being soaked in water?

Compared with traditional wood boards, WPC wall panels have much better anti-mold performance. However, it is still recommended to keep the environment well-ventilated and dry and wipe and clean them regularly.

How much more expensive are WPC wall panels than PVC?

This price difference mainly reflects that WPC materials have a higher cost, a more complex production process, and offer better texture and environmental performance.

Do WPC wall panels used outdoors need special waterproof treatment?

Choose WPC wall panels specially designed for outdoor use. These products usually contain UV stabilizers and special waterproof additives, significantly enhancing weather resistance and having a service life of 15 to 20 years.

About Ecoxplank WPC

We are a leading WPC wall panel manufacturer in China, dedicated to the research and development and production of high-performance wood-plastic composite materials for over 15 years.

Our products adopt unique formulas and advanced processes, offering industry-leading waterproof performance (24-hour water absorption rate <0.8%) and environmental protection certifications. They are widely used in high-end residential and commercial projects around the world.

For more information about the Ecoxplank WPC waterproof wall panel products or to obtain free samples for testing their waterproof performance, please contact our professional advisors.

Last update: April 2025

5 thoughts on “Are WPC Wall Panels 100% Waterproof?”

Looking for a solid online casino in the Philippines? Solaire Online is worth a look. Easy to navigate and they’ve got all the popular games. Give it a shot! solaireonline

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Yo! PHBet777 is my go-to spot. Easy to navigate, great odds, and always pays out quick. Seriously, give phbet777 a shot. You might just get lucky!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/register-person?ref=IXBIAFVY

Comments are closed.