Can You Screw Composite Decking?

This article shows you the correct installation method to fix the decking with special screws. It ensures your floor is safe, stable, and visually appealing.

Can You Use Screws on Composite Decking?

Yes, but you need to be careful.

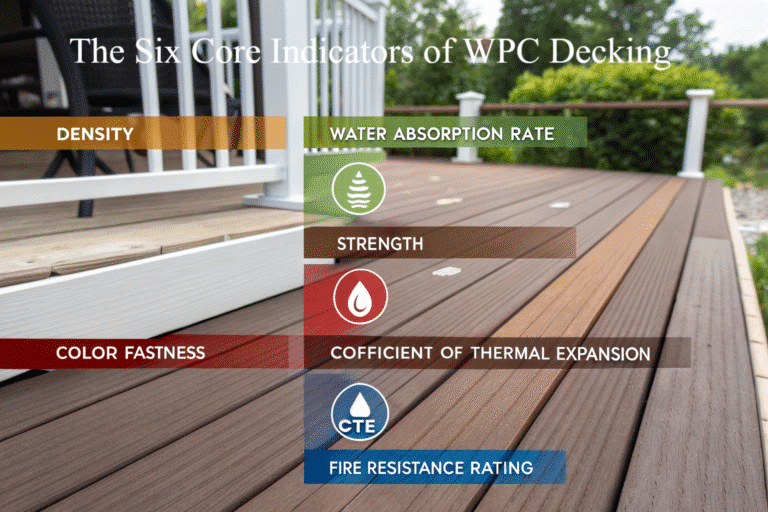

Composite decking is made of wood fibers and plastic, which gives it a higher density. Traditional wood installation tools and methods may not work. To ensure a secure fit and avoid damage, it’s recommended to use screws designed specifically for WPC decking and follow the correct installation method.

- Hollow WPC deck: It’s not recommended to fix directly with screws, as the hollow structure cannot effectively grip the screws, which may lead to looseness or instability.

- Solid WPC deck: Screws can be used, but pre-drilling is necessary to avoid cracking due to uneven pressure.

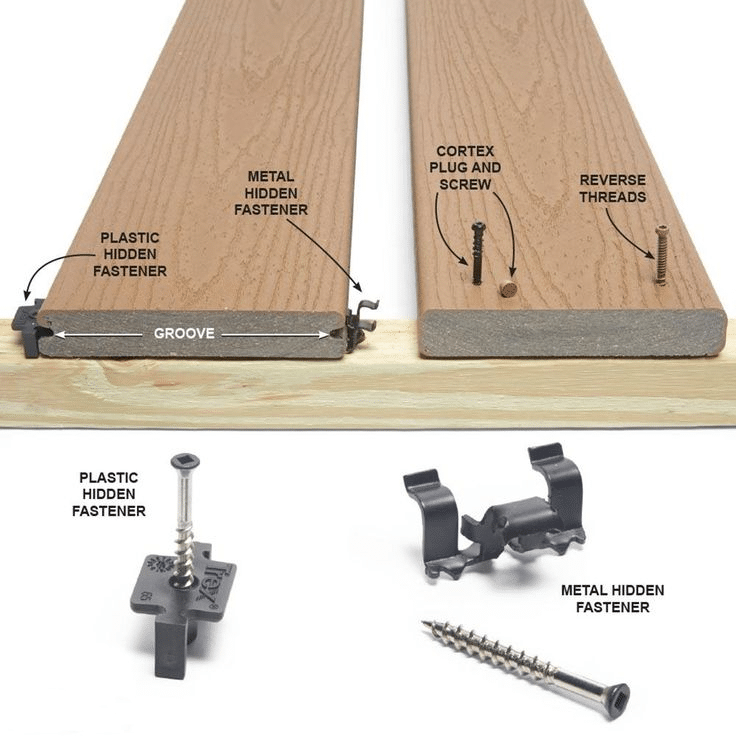

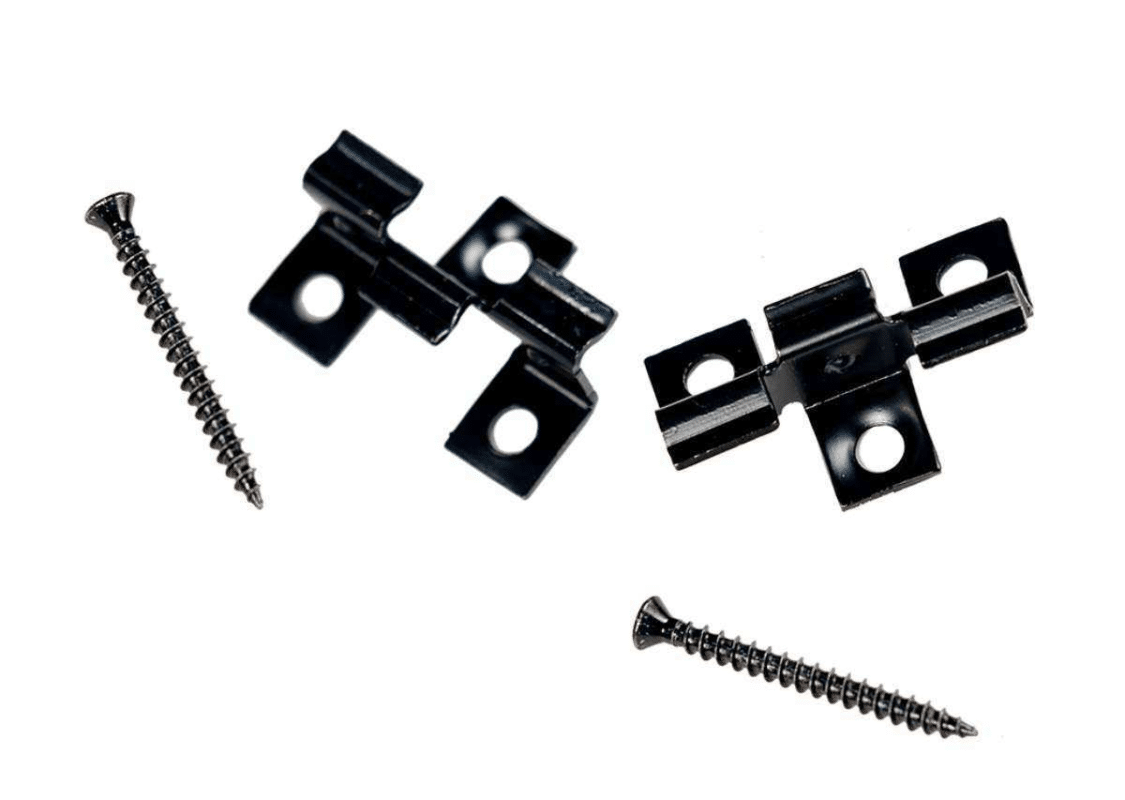

The best installation way for composite decking is to use hidden fasteners, as this helps avoid exposed screws, maintain a clean appearance, and reduce potential damage.

Factors to Consider When Using Screws as Fixings for Securing WPC Decking

Not recommended: Nails

Nails are not suitable for fixing plastic decking. They do not provide sufficient holding power and grip, which can lead to instability and loosening over time. Additionally, the heads of nails may be exposed, affecting the appearance and increasing the risk of corrosion. In contrast, screws designed specifically for composite decking are much more reliable and provide a much stronger, more secure fastening.

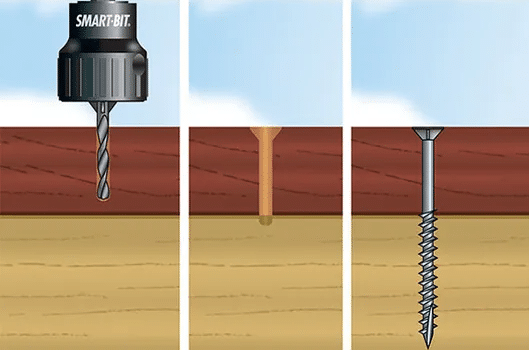

The necessity of pre-drilling

Composite decking is generally denser than wood. Pre-drilling is absolutely necessary when using screws. Pre-drilling effectively prevents the WPC boards from cracking or splitting.

It ensures that screws go in smoothly and remain firmly in place. This method ensures even pressure from the screws, minimizing damage to the material and extending the decking’s lifespan.

Considering using hidden fastener as composite decking fixings

The hidden screw fastening method not only enhances the appearance of WPC panels but also reduces potential damage caused by exposed screws.

By hiding the screw heads, the surface of the decking becomes smoother and neater, while also preventing rusting or surface damage to the composite decking. Using hidden fasteners also allows the material to expand and contract freely with temperature changes, reducing damage caused by improper fastening and increasing the decking’s durability.

Recommended Types of Screws for Fastening Composite Decking Board

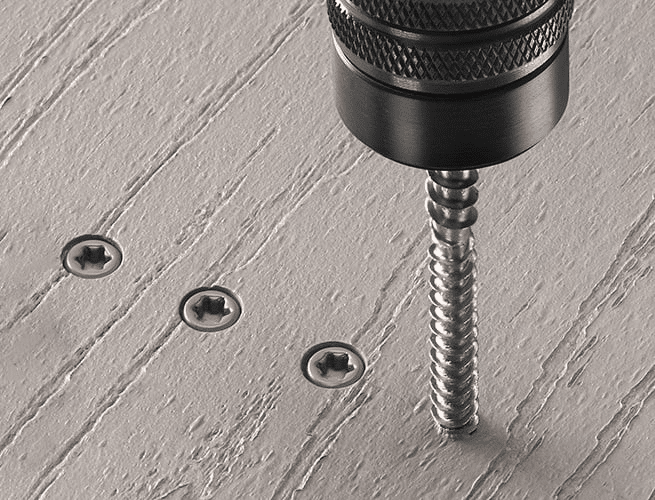

Composite decking screws are the best screws, specifically designed for high-density composite materials. They feature optimized threads and compact, smooth screw heads to ensure a secure fix without affecting the deck’s appearance.

Typically, composite decking screws have reverse threads, which reduce pressure during installation, lower the risk of cracking, and improve the fastening effect. Additionally, they use high-strength materials, such as stainless steel, which enhances durability and prevents loosening or corrosion over time.

The star drive design of these screws allows a better grip on the driver bit, whether using a screwdriver or power tool. This improves torque transfer and installation stability. Compared to traditional Phillips or slotted screws, the star drive design reduces slippage, improving accuracy and efficiency during installation.

Compared to wood screws, composite decking screws have deeper and thicker threads, optimized for composite surfaces. They provide better fastening and prevent loosening.

Wood screws, with smaller threads, cannot effectively grip the high-density structure of composite decking. They loosen easily, are less corrosion-resistant, and may cause cracking or damage. Therefore, wood screws are unsuitable for installing composite decking, especially in outdoor environments.

Watch the video below for more information about composite decking screws.

Composite Decking Screw Fixing Methods

Fixing Method - Face Screw Fixing

Face screw fixing involves driving screws directly through the surface of the composite decking into the underlying support structure (such as timber bunnings). This method is simple and fast, commonly used for solid composite decking, as the solid structure can effectively bear the holding force of the screws.

However, for hollow composite decking, face screw fixing is not recommended. The hollow sections cannot effectively grip the screws, which may lead to loosening and instability.

Please watch the video below to learn more about this fixing.

Features:

- Simple and Easy: Face screw fixing is easy to operate, making it suitable for quick installation.

- Suitable for Solid Composite Decking: The solid structure of the decking can effectively bear the direct fixing force of the screws.

- Exposed Screw Heads: A downside of face screw fixing is that the screw heads are usually exposed on the surface of the decking, which can affect its appearance.

Solution to Improve Appearance

To address the issue of exposed screw heads, a common solution is to use screws with caps.

After installation, small caps that match the decking color are used to cover the screw heads. This not only maintains the aesthetics of the surface but also prevents corrosion or wear caused by exposed screws.

Composite Deck Screw Fixing Installation Tips

1. Pre-Drilling Holes for Composite Decking

Check out the video below to learn more

2. Correct Spacing and Alignment

This allows the decking to expand and contract freely with temperature changes, preventing loosening or warping.

3. Maintaining Even Spacing of Composite Decking Screws

4. Proper Screw Length for Composite Decking

For example, a 1-inch thick composite deck should use screws that are 2.5 inches (64 mm) long, and a 1.25-inch thick deck should use 3-inch (76 mm) long screws.

This allows the decking to expand and contract freely with temperature changes, preventing loosening or warping.

5. Use the Right Caps

How to install Composite decking with screws?

1. Essential Tools

- Electric Screwdriver or Drill: Used to quickly and evenly drive screws, saving time.

- Pre-drilling Tool: Used for drilling holes in the decking to prevent cracking. A 3mm drill bit is typically recommended.

- Tape Measure: Ensures accurate spacing and alignment of each decking board during installation.

- Level: Ensures the decking is installed evenly, preventing any uneven or slanted sections.

- Pencil: Used to mark the positions for pre-drilling, ensuring precise installation.

- Screws: Screws specifically designed for composite decking, featuring deeper threads and corrosion-resistant materials for a secure fix.

- Caps (Optional): Caps that match the decking color, used to cover the screw heads for a neat, aesthetic finish.

- Angle Gauge: Helps ensure consistent spacing between decking boards, preventing uneven gaps.

- Safety Equipment: Gloves and safety goggles to protect your hands and eyes during installation, preventing accidental injury.

2. Installation Steps

I. Ground Preparation and Joist Positioning

- Ensure the ground is level, dry, and free of debris.

- Pre-drill holes on the joists.

II. Composite Decking Installation

- Pre-drilling: Drill holes in the composite decking, slightly smaller than the screw diameter (recommend a 3mm drill bit).

- Install the First Decking Board: Align the board with the support structure, then use an electric screwdriver to secure screws, placing one every 30-40 cm.

- Install Subsequent Decking Boards: Ensure even screw spacing and maintain proper expansion gaps.

- Use starter clips to fix the first board, leaving an 8mm gap from the wall, then lay the subsequent boards, maintaining a 6mm expansion gap between each (specific instructions may vary by supplier).

III. Adjustment and Aesthetics

- Use a tape measure and angle gauge to ensure consistent spacing and alignment between the boards.

- Optionally, install caps to cover the screw heads and maintain the deck’s appearance.

IV. Inspection and Cleanup

- Check that all screws are properly tightened and the decking surface is level.

- Clean the area, removing any excess tools and debris.

V. Maintenance and Care

- Clean the decking surface after installation.

- Perform regular maintenance using a mild soap water solution.

Why is it not recommended to drive screws directly into composite decking?

Potential Drawbacks

Possible Damage to the Decking:

Composite decking has a different density and structure compared to traditional wood. Driving screws directly into it may cause the material to crack, split, or suffer other damage, affecting the structural integrity and lifespan of the decking.Void the Warranty:

Most composite decking warranties specify installation requirements. Using improper methods, such as driving screws directly into the decking, can violate these terms. If issues arise, the manufacturer may refuse warranty coverage. Therefore, users must strictly follow the manufacturer’s installation instructions.Aesthetic Issues:

Exposed screw heads detract from the overall appearance of the decking. They are also prone to rust and corrosion, which can cause staining, fading, and warping, and are more likely to scratch the surface of the decking.

Long-Term Effects

Loosening of Screws:

Over time, screws may loosen due to the expansion and contraction of the decking material. This can lead to an unstable deck, negatively affecting the overall user experience.Warping and Uneven Wear:

Improper fixing can cause localized stress, leading to warping or uneven wear of the decking. This impacts both the performance and appearance of the deck.Increased Maintenance Costs:

Loose screws or warped decking may require frequent repairs, increasing long-term maintenance costs.Difficult and Expensive Repairs:

Once screws are used to secure the decking, the repair process becomes more complicated and costly. If problems arise, removing composite deck screws and dismantling the damaged sections requires more time and effort. Additionally, part of the decking may need to be replaced, which not only affects the user experience but also adds extra costs.

Summary:

Driving screws directly into the decking may cause loosening, warping, and uneven wear, increase maintenance costs, and make repairs more complex and expensive.

Alternative Installation Methods

These best composite decking hidden fasteners effectively prevent exposed screws, maintaining a clean appearance while enhancing the stability and durability of the fixings. They are an ideal choice for improving the aesthetics and extending the lifespan of the decking.

Composite Decking Starter Clips

Composite Decking Starter Clips are used to secure the first and last boards in each row, providing stability and support at the outer edges. These fasteners typically connect to the ends of the boards and, during installation, do not penetrate the decking surface, maintaining a clean appearance.

Similarly, composite trim screws are used to secure trim pieces made from composite materials. Their design ensures a strong connection and integrates perfectly with the decking surface, preventing exposed screw heads and further enhancing the overall aesthetic.

Advantages of Starter Clips:

- Easy Installation: No pre-drilling required, quick and convenient, saving time and effort.

- Enhanced Aesthetics: Prevents exposed screw heads, keeping the surface neat and improving the overall appearance.

- Additional Support: Provides extra edge support, reducing the risk of WPC decking damage and ensuring stability.

- Maintains Deck Integrity: Since it doesn’t penetrate the decking surface, it reduces the risk of cracking or damage caused by screws.

Overall, Starter Clips offer a convenient and aesthetic fastening solution, especially for composite decking installations that require maintaining both appearance and the integrity of the deck.

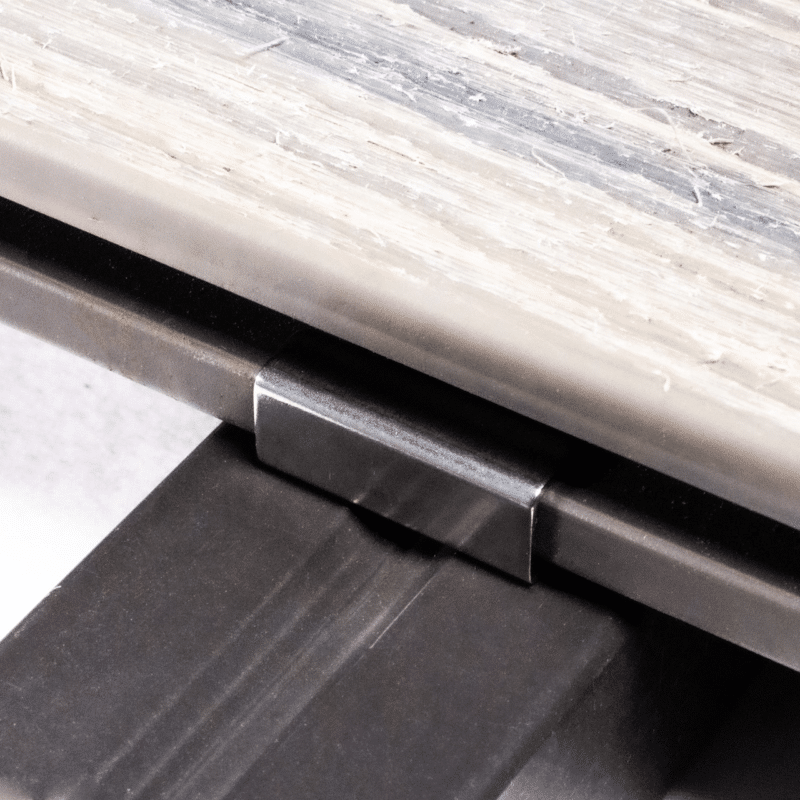

Hidden Fasteners for WPC decking

Hidden Fasteners hide the screws and fasteners in the side or gaps of the decking, preventing exposed screw heads and providing a cleaner appearance.

This installation method results in composite decking with no screws exposed. It not only enhances aesthetics but also reduces the risk of corrosion and wear caused by exposed screws.

Advantages of Hidden Deck Fastening System:

- Enhanced Aesthetics: The screws and fasteners are hidden within the decking, preventing exposed screw heads and improving the overall appearance.

- Prevents Corrosion: Since the screws are not exposed to external elements, the risk of rusting is reduced, maintaining both the appearance and durability of the decking.

- Strong Durability: High-quality materials ensure long-lasting performance, even in outdoor environments, capable of withstanding prolonged use and weather changes.

- Allows Natural Expansion and Contraction: The design of the fasteners allows the decking to expand and contract freely with temperature changes without affecting the structural integrity, reducing the risk of damage caused by environmental shifts.

See more recommendations on composite decking clips screwfix hidden fasteners here

Summary:

Using screws to install WPC decking is feasible but requires careful selection of the appropriate screw type and fastening method. It is recommended to use hidden fasteners and screws designed specifically for floor decking, avoiding direct screwing into the boards to ensure the aesthetics, durability, and long-term stability of outdoor decks. To maintain warranty validity, it is best to follow professional installation guidelines.

Ecoxplank will provide you with any necessary guidance on composite decking.

FAQ

Do I need to pre drill composite deck screws?

Yes.

It is recommended to pre-drill before inserting screws into composite wood. Composite materials are denser and harder than wood, and pre-drilling helps prevent cracking and ensures the screws insert smoothly. Typically, a 3mm drill bit is used for pre-drilling.

How do you hide screws in composite decking?

You can hide screws by using caps or hidden fasteners. After inserting the screws, you can insert caps made of composite materials that match the decking color, effectively hiding the screw heads and creating a smooth finish. Another method is using hidden deck fasteners at the edges of the decking, which also keeps the surface clean.

Can you use regular screws on composite decking?

It is not recommended to use regular wood screws for composite decking, as these screws are not designed for the density and structure of composite materials. Regular screws may not grip well and can cause cracking, deformation, or loosening.

Additionally, they lack corrosion-resistant coatings, leading to rust and affecting the decking’s durability. It is best to use screws designed specifically for composite decking, which have the right threads and corrosion protection.

Is it possible to screw composite boards from underneath?

Yes.

You can screw composite boards from underneath, especially when using hidden fasteners. This method helps keep the surface clean and prevents screw exposure.

It also reduces the impact of temperature changes on the decking’s expansion and contraction, as the fastener design allows for natural movement, enhancing the decking’s stability and durability.

What screws to use with composite decking?

Use screws that are specifically designed for composite materials when installing composite decking.

These screws typically have deeper threads and corrosion-resistant coatings to withstand long-term exposure to outdoor elements and climate changes, ensuring a secure and durable installation.

These screws are also often designed to match the decking’s color, providing a more seamless appearance.

Why do composite deck screws have two threads?

Composite deck screws often feature a dual-thread design to improve grip in dense composite materials. One thread cuts into the material, while the other provides stronger holding power.

This design enhances the screw’s holding strength, prevents loosening, and reduces pressure on the decking material, lowering the risk of cracking.

Why do composite deck screws have star heads?

Composite deck screws have star heads for several reasons:

- Better Torque Transfer and Grip: The star head design improves torque transfer and grip, making the screw tighter.

- Reduced Slippage: It minimizes the risk of slippage during tightening or loosening, improving installation consistency.

- Durability: Star-headed screws are corrosion and wear-resistant, making them ideal for outdoor use.

- Better Alignment and Accuracy: The design helps reduce screw misalignment, ensuring precise installation.

- Aesthetic: Star heads hide the fastener system, maintaining a clean decking surface.

- Self-Drilling: Star-head screws are self-drilling, allowing them to quickly penetrate wood and are suitable for various materials.

Why are wood screws unsuitable for composite decking?

Composite decking is made from a blend of wood fibers and plastic, which makes it denser and more durable than wood. Regular wood screws cannot provide enough holding power and may cause cracking, loosening, or warping of the decking.

On the other hand, screws specifically designed for composite decking have optimized threads and materials that better grip the decking surface, providing a more secure hold and reducing the risk of damage. Therefore, it’s recommended to use specialized screws or hidden fasteners to ensure stability, durability, and aesthetic appeal.

Decking Materials and Installation Guide. Retrieved December 23, 2024, from decks.com

Hidden Fasteners-Source: Ecoxplank

Composite Deck-Source: Ecoxplank

5 thoughts on “Can You Screw Composite Decking?”

some truly quality posts on this website , saved to fav.

https://bonusbacklinks.com/

Need my daily dose of entertainment? 88vintv has got it covered! Easy to use, great selection. Check it out: 88vintv.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

FB68nohu… sounds interesting. Im a no-hu type of guy so ill def give it a look. Hoping for some big wins in the near future. Try your luck here fb68nohu

Comments are closed.