Deck Joist Spacing: The Ultimate Guide for Contractors and Builders

Building a deck that lasts starts with a solid foundation. You likely grapple with building codes, material choices1, and client expectations. But have you considered the critical role of joist spacing.

Correct joist spacing ensures a stable, safe, and durable deck. It prevents sagging, bouncing, and premature failure, keeping your clients happy and protecting your reputation. For WPC decking, manufacturers commonly recommend 16 inches on-center (OC) for perpendicular installation, and 12 inches OC for diagonal.

However, simply following standard recommendations isn’t enough. This guide dives deep into the nuances of joist spacing, especially for WPC decking2, empowering you to build decks that stand the test of time.

Why Joist Spacing Matters for Decks?

Imagine building a beautiful deck, only to have it sag and wobble within a few years. You face callbacks, warranty claims, and a damaged reputation. This is the reality of improper joist spacing.

Joist spacing directly affects a deck’s structural integrity3. Wider spacing can lead to excessive deflection (bending) of the decking boards, creating a bouncy, unstable surface and increasing the risk of failure.

Beyond Structural Integrity: The Ripple Effects

Proper joist spacing isn’t just about preventing immediate collapse. It’s about long-term performance and avoiding a cascade of problems:

- Safety: A stable deck is a safe deck. Proper spacing minimizes the risk of trips, falls, and structural failure.

- Aesthetics: Even slight sagging can be noticeable and detract from the deck’s appearance.

- Warranty Compliance: Most WPC decking manufacturers have specific joist spacing requirements. Failing to follow them can void the warranty, leaving you and your client vulnerable.

- Client Satisfaction: A well-built deck, with proper joist spacing, will last longer and perform better, leading to happier clients and positive word-of-mouth referrals.

Understanding Deck Joist Spacing Standards?

Confused by conflicting information about joist spacing? You’re not alone. There are general guidelines, manufacturer specifications, and local building codes4 to consider. The problem is navigating this complex landscape.

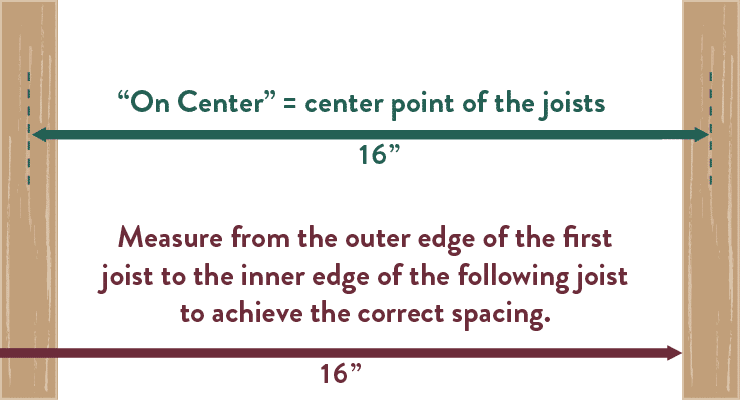

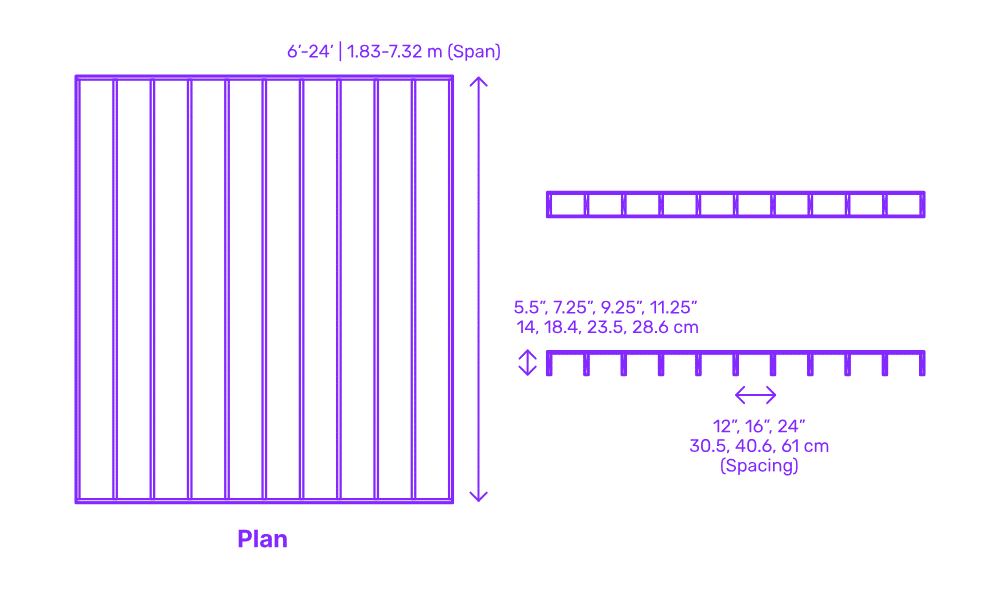

Standard residential deck joist spacing is typically 16 inches on-center (OC). For WPC decking installed diagonally, this is reduced to 12 inches OC. However, always check the manufacturer’s instructions5 and local building codes.

Decoding the Standards: A Deeper Look

Let’s break down the common standards and their limitations:

- 16 Inches OC: This is the most common recommendation for standard residential decks with decking boards installed perpendicular to the joists. It’s a good starting point, but it’s not a one-size-fits-all solution.

- 12 Inches OC: This tighter spacing is often required for:

- Diagonal decking installations (because the actual span is longer).

- Heavier loads (hot tubs, large planters, etc.).

- Commercial applications.

- Thinner or hollow-core WPC decking boards.

- 24 Inches OC: Some WPC manufacturers, particularly those with reinforced boards like WearDeck, may allow 24-inch spans, but this is typically only for very specific, light-duty residential applications. Don’t assume this is permissible without explicit confirmation from the manufacturer.

The Golden Rule: Manufacturer’s Instructions and Local Codes

Always, always prioritize the WPC manufacturer’s installation guide and your local building codes. These supersede any general guidelines.

- Manufacturer’s Guide: Each WPC product has unique properties that dictate the optimal joist spacing. The manufacturer’s guide will provide specific recommendations based on the board’s thickness, profile (solid or hollow), and intended use.

- Local Building Codes: Building codes are the law. They may have stricter requirements than the manufacturer’s recommendations. Failure to comply can lead to failed inspections and costly rework.

Factors Influencing Joist Spacing?

Are you making the mistake of applying a "one-size-fits-all" approach to joist spacing? Many builders do, leading to problems down the road. Factors beyond the standard 16 inches OC must be considered.

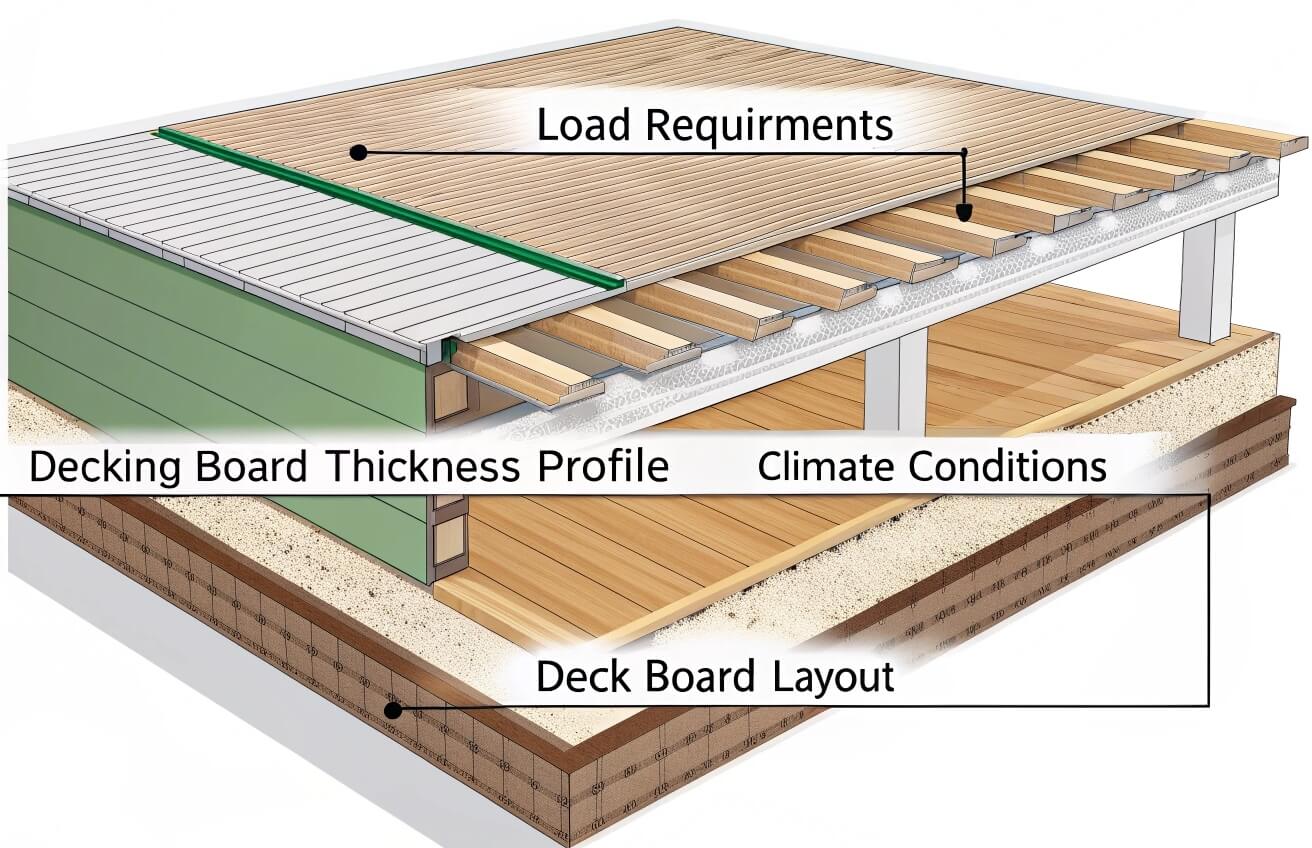

The primary factors influencing joist spacing are load requirements6, decking board thickness and profile, climate, and deck board layout7. Ignoring these can compromise the deck’s structural integrity and longevity.

Deep Dive into the Influencing Factors

Let’s examine each factor in detail:

Load Requirements

This is arguably the most critical, yet often underestimated, factor.

- Standard Residential Use: Typical foot traffic and some furniture. 16 inches OC may be sufficient, if the manufacturer allows it.

- Heavy Loads: Hot tubs, large planters, built-in kitchens, or high-traffic areas demand reduced spacing, often 12 inches OC or even less.

- Commercial Applications: Commercial decks always require tighter spacing (12 inches OC or less) and may need specific engineering calculations. Some WPC manufacturers provide tables with different spans for residential vs. commercial usage.

Decking Board Thickness and Profile

- Thinner Boards: Thinner WPC decking boards deflect more, requiring closer spacing.

- Hollow vs. Solid: Hollow boards might need tighter spacing.

Thinner and hollow-core boards require closer joist spacing compared to thicker, solid boards. While a 25.4mm (1-inch) solid board might allow for 16-inch on-center spacing, thinner or hollow-core boards typically need 12-inch or even closer spacing. For example: 21mm thick board – Max 400mm joist span; 25mm thick board – Max 450mm joist span; 30mm thick board – Max 500mm joist span. Always refer to and strictly adhere to the manufacturer’s guidelines.

Experienced contractors prioritize manufacturer data, building codes, and often choose a spacing slightly less than the maximum to achieve optimal performance and feel, while also remembering to comply with weight limits for joist spacing.

Climate and Environmental Conditions

- Temperature Fluctuations: WPC expands and contracts with temperature changes. Extreme swings necessitate closer spacing.

- Moisture Exposure: High rainfall/humidity areas may need closer spacing for better ventilation and moisture control.

- UV Exposure: It’s a factor that might affect the spacing and spans.

Deck Board Layout

- Perpendicular: Standard 16 inches OC may be sufficient, if allowed by the manufacturer.

- Diagonal (45 degrees): Always reduce spacing to 12 inches OC. The diagonal span is effectively longer.

- Herringbone or Other Complex Patterns: These require even tighter spacing, and likely additional blocking.

Substructure Material

WPC joists or treated pinewood joists are recommended. 3

Drainage

There should be a slight slope, ideally around 2%, to facilitate water drainage away from the decking.

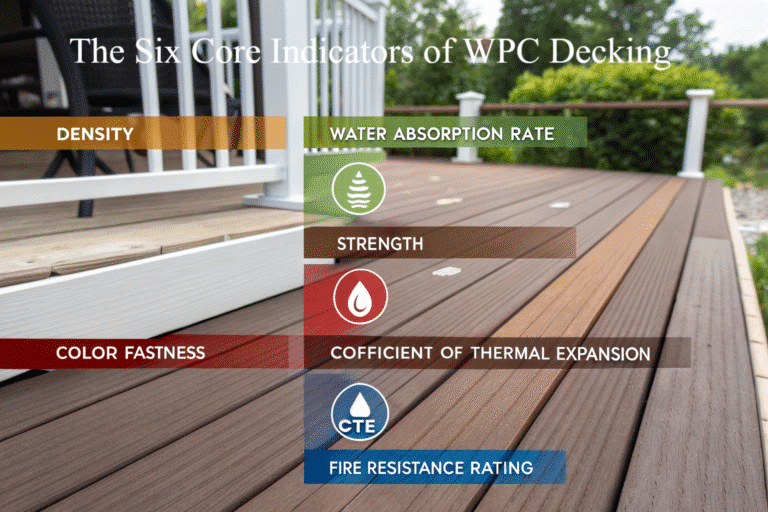

WPC Decking: Special Considerations for Joist Spacing?

Thinking WPC decking is just like wood when it comes to joist spacing? This is a dangerous misconception. WPC has unique properties that demand special attention.

WPC decking expands and contracts more than traditional wood. This requires careful consideration of gapping and joist spacing to prevent buckling, warping, or excessive gaps.

The Science of WPC Expansion and Contraction

WPC’s coefficient of thermal expansion dictates how much it expands and contracts with temperature changes. This must be factored into the installation.

Gapping: The Essential Breathing Room

Proper gapping is absolutely crucial:

- Between Boards: Leave the manufacturer-recommended gap between boards.

- At Ends: Leave a gap where boards meet walls or other structures.

- Butt Joints: Where two boards meet end-to-end, double joists are often recommended. 5 Specific gapping might be recommended based on temperature ranges (e.g., 3/16" gap below 32°F, 1/8" gap between 33°F and 74°F, and 1/32" gap above 75°F).6

Fasteners: The Right Choice for WPC

- Type and Material: Use fasteners specifically designed for WPC decking (stainless steel or coated screws).

- Hidden Fasteners: Many WPC systems use hidden fastener clips. Proper installation is key to their effectiveness.

- Over-Driving: Avoid over-driving screws, which can damage the WPC.

Substructure Considerations for WPC

- Joist Material: While treated lumber is common, WPC joists are becoming more popular.

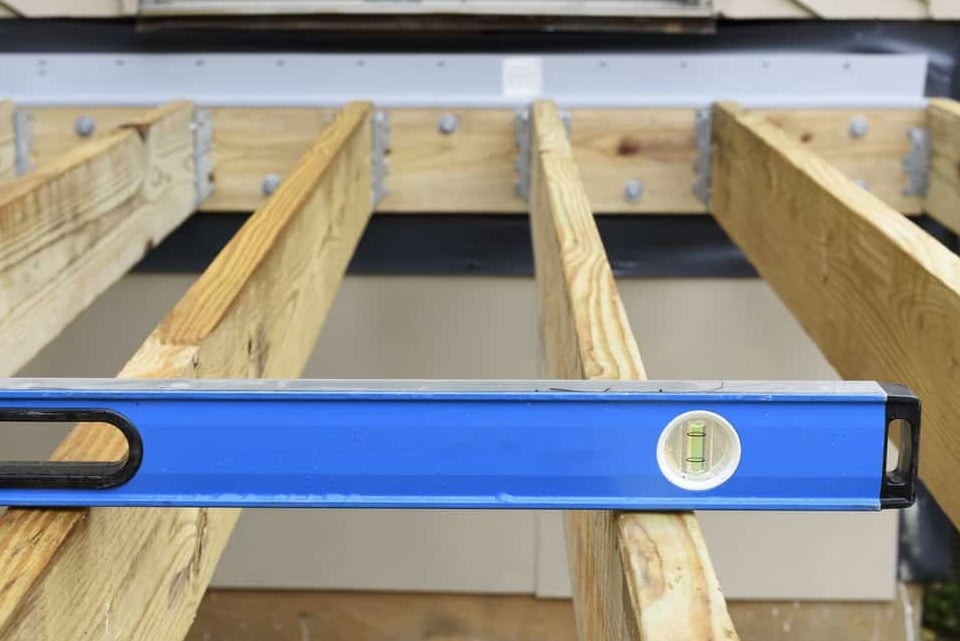

- Joist Leveling: Use shims for a perfectly level substructure.

- Drainage and Ventilation: Ensure adequate drainage and airflow.

Step-by-Step Guide to Calculating Joist Spacing?

Feeling overwhelmed by all the factors involved in calculating joist spacing? It’s not as daunting as it seems. A systematic approach, using this step-by-step guide, can simplify it.

The key to calculating joist spacing is to start with the WPC manufacturer’s recommendations8, then adjust based on load, board layout, and local building codes9.

Step-by-Step Calculation Process

-

Consult the Manufacturer’s Guide: This is your starting point. Find the recommended spacing for your specific WPC product, considering:

- Board thickness and profile (solid or hollow).

- Intended use (residential or commercial).

- Installation orientation (perpendicular or diagonal).

-

Determine Load Requirements:

- Standard Residential: If the manufacturer’s recommendation is 16 inches OC, and you have only typical loads, you may be able to proceed.

- Heavy Loads: If you have a hot tub, large planters, or other heavy items, reduce spacing to 12 inches OC or less, as per the manufacturer’s guidelines or an engineer’s calculations.

- Commercial: Use 12 inches OC or less, and consult an engineer if necessary.

-

Consider Deck Board Layout:

- Perpendicular: You can likely use the manufacturer’s standard recommendation (assuming it meets load requirements).

- Diagonal: Reduce spacing to 12 inches OC.

- Herringbone or Other Complex Patterns: Consult the manufacturer and consider even tighter spacing and additional blocking.

-

Check Local Building Codes:

- Your local codes may have specific requirements that supersede the manufacturer’s recommendations. Always comply with local codes.

-

Calculate the Number of Joists:

- Measure the length of your deck (in feet).

- Convert the joist spacing from inches to feet (e.g., 16 inches = 1.33 feet).

- Divide the deck length by the joist spacing (in feet).

- Add one to account for the starting joist.

- Round up to the nearest whole number. This is the number of joists you need.

-

Double Joist Installation:

Double joists should be installed wherever two decking boards meet. 5 -

Ground preparation:

Ensure that the ground surface is level, remove any weeds, and lay a root-stop fabric. 5Example Calculation

Let’s say you’re building a 16-foot-long deck with WPC decking that recommends 16 inches OC for standard residential use. You’re installing the boards perpendicularly, and your local codes don’t have stricter requirements.

- Manufacturer’s Recommendation: 16 inches OC.

- Load Requirements: Standard residential.

- Deck Board Layout: Perpendicular.

- Local Codes: No stricter requirements.

- Calculate Number of Joists:

- Deck length: 16 feet.

- Joist spacing: 16 inches = 1.33 feet.

- 16 feet / 1.33 feet = 12.03

- 12.03 + 1 = 13.03

- Round up to 14 joists.

You would need 14 joists, spaced 16 inches apart on center.

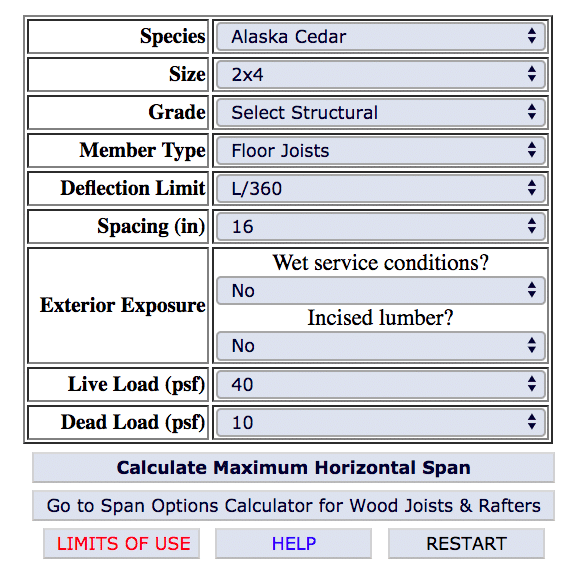

Joist Spacing Calculator: Quick Determination Tools?

Need a faster way to determine optimal joist spacing? While understanding the principles is crucial, online calculators and resources can provide a quick check.

Joist spacing calculators are helpful tools, but they should not replace the manufacturer’s instructions or local building codes. Always use them as a supplementary resource, not the final authority.

Types of Calculators and Resources

- Online Calculators: Many websites offer free deck joist spacing calculators10. These typically ask for inputs like deck dimensions, joist material, decking material, and desired spacing.

- Manufacturer’s Websites: Some WPC manufacturers provide calculators specific to their products.

- Mobile Apps: There are also mobile apps available for calculating joist spacing.

- Span Tables: refer to span tables provide by your supplier.

Limitations of Calculators

- Generic Calculations: Most online calculators use generic formulas and may not account for the specific properties of your WPC product.

- Limited Input Options: They may not have options for all the factors that influence joist spacing (e.g., climate, specific WPC profiles).

- Code Compliance: Calculators may not be up-to-date with the latest building codes.

Using Calculators Wisely

- Use as a Starting Point: Get a preliminary estimate of joist spacing.

- Cross-Reference: Compare the calculator’s results with the manufacturer’s recommendations and local codes.

- Prioritize Manufacturer and Codes: If there are discrepancies, always follow the manufacturer’s instructions and local building codes.

- Consider seeking expert help if you are unsure.

Common Mistakes and How to Avoid Them?

Knowing the common pitfalls in deck joist spacing can save you time, money, and headaches. Even experienced builders can make these mistakes, leading to costly consequences.

The most common mistakes in deck joist spacing include ignoring manufacturer guidelines, underestimating loads, insufficient gapping, poor drainage, improper fastener use, and neglecting local building codes.

Mistake #1: Ignoring Manufacturer Guidelines

This is the cardinal sin of deck building. Every WPC product is different. The manufacturer’s instructions are not optional.

Solution: Always, without exception, consult and follow the manufacturer’s installation guide for your specific WPC product.

Mistake #2: Underestimating Load

This leads to sagging, bouncing, and potential structural failure. Standard spacing assumes typical residential use.

Solution: Carefully consider all potential loads (furniture, hot tubs, high traffic) and reduce joist spacing accordingly. Consult an engineer if necessary, especially for commercial applications.

Mistake #3: Insufficient Gapping

WPC expands and contracts. Insufficient gapping causes buckling and warping.

Solution: Follow the manufacturer’s recommendations for gapping between boards, at ends, and at butt joints. Double joists at butt joints are often recommended.5

Mistake #4: Poor Drainage

Trapped moisture leads to rot, mildew, and premature deterioration.

Solution: Ensure the substructure allows for adequate water drainage and airflow beneath the deck. Consider WPC joists for superior rot resistance.

Mistake #5: Improper Fastener Use

Using the wrong fasteners, or installing them incorrectly, compromises the deck’s integrity.

Solution: Use fasteners specifically designed for WPC decking (stainless steel or coated screws). Use hidden fastener clips if appropriate, and avoid over-driving screws.

Mistake #6: Ignoring Local Building Codes

This can lead to failed inspections, fines, and costly rework.

Solution: Always check and comply with your local building codes, which may have stricter requirements than the manufacturer’s recommendations.7 4

Mistake #7: Not Allowing Time for Acclimation

WPC decking needs time to adjust to the local temperature and humidity before installation.

Solution: Allow the WPC boards to acclimate to the environment for the manufacturer-recommended time before installation.

Mistake #8: Using Inadequate Cutting Tools

Solution: Using proper tools.

Choosing the Right WPC Decking: A Contractor’s Guide to Optimal Joist Spacing

Frustrated with decking materials that warp, rot, or fade? You want a product that delivers long-term performance and beauty, minimizing callbacks and maximizing client satisfaction.

Ecox WPC offers a superior decking solution, combining the beauty of wood with the durability and low maintenance of composite materials. Our products are engineered for exceptional performance and longevity.

Why Choose Ecox WPC?

-

Optimal Spacing Flexibility: Ecox’s advanced formulations allow for wider joist spacing (up to 16 inches OC) without compromising stability, saving you time and material costs.

-

Climate Resilience: Designed to withstand extreme temperatures and high humidity, Ecox WPC minimizes expansion and contraction, reducing the risk of warping or buckling.

-

Eco-Friendly & Durable: Made from recycled materials, Ecox WPC is resistant to rot, insects, and UV damage, ensuring long-lasting beauty and performance.

By carefully evaluating the product specifications and following Ecox WPC’s installation guidelines, you can ensure optimal joist spacing for a long-lasting, beautiful deck. Ecox WPC’s commitment to quality, sustainability, and comprehensive technical support, along with features, such as resistance to rot, insects, and fading, further enhances its appeal as a reliable decking choice.

Additionally, Ecox WPC has advanced, automated facilities, with over 150 production lines, and is strategically located for access to low-cost raw materials.

Get Started Today

Ready to build decks that exceed expectations? Ecox WPC provides the perfect balance of strength, aesthetics, and ease of installation.

Choose Ecox WPC—where innovation meets reliability.

FAQ

Should I use 16 or 24 joist spacing for a deck?

It depends on the decking material, load requirements, and local building codes. 16 inches OC is common for residential decks, but 24 inches OC may be allowed for some WPC products under specific conditions. Always consult the manufacturer and local codes.

What is the standard spacing for WPC deck joists?

16 inches OC for perpendicular installation, and 12 inches OC for diagonal installation are common, but always check the manufacturer’s instructions.

What are the best practices for spacing joists on a composite deck?

Follow the manufacturer’s guidelines, consider load requirements, account for expansion and contraction, ensure proper drainage, and comply with local building codes.

How does joist spacing affect the overall stability of a deck?

Proper joist spacing prevents excessive deflection (bending) of the decking boards, ensuring a stable and safe deck surface.

Are there specific joist spacing requirements for different types of decking materials?

Yes, different decking materials (wood, WPC, PVC) have different properties and therefore different joist spacing requirements.

What are the consequences of improper joist spacing in deck construction?

Sagging, bouncing, premature failure, voided warranties, and potential safety hazards.

How do local building codes influence deck joist spacing?

Local building codes may have specific requirements that supersede manufacturer recommendations. Always comply with local codes.7 4

Sources:

-

Choosing the right materials can significantly impact your deck’s longevity and appearance. Discover expert recommendations on materials here. ↩

-

WPC decking requires specific installation techniques. Discover expert advice on installation to ensure longevity and performance. ↩

-

Learn how proper joist spacing is vital for maintaining a deck’s structural integrity and preventing future issues. ↩ ↩

-

Local building codes are vital for legal compliance and safety. Learn more about their impact on your deck project. ↩ ↩ ↩

-

Manufacturer’s instructions ensure proper installation and safety. Discover why they are essential for your project. ↩ ↩ ↩ ↩ ↩

-

Understanding load requirements is crucial for ensuring your deck’s safety and longevity. Explore this link for detailed insights. ↩ ↩

-

The layout of your deck boards can significantly impact structural integrity. Discover the best practices for optimal spacing. ↩ ↩ ↩

-

Manufacturer recommendations ensure compliance with safety standards and optimal performance. Check this resource for detailed insights. ↩

-

Local building codes can significantly impact your project. Familiarize yourself with these regulations to avoid costly mistakes. ↩

-

Explore this link to find reliable online calculators that can help you quickly determine optimal joist spacing for your projects. ↩

6 thoughts on “Deck Joist Spacing: The Ultimate Guide for Contractors and Builders”

Great casino, huh? Decent selection, but nothing I’d write home about. Check them out if you’re curious: phgreatcasinolink

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Maintaining the structural integrity of a deck is why I tend to avoid this level of DIY project. We have a lot of the necessary tools and materials, but sometimes an expert is the best course of action.

Heard about giftcode79club from a friend and decided to check it out. Man, they got some pretty sweet deals! It’s definitely worth a look if you’re hunting for bonuses. You can find them here giftcode79club

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.info/en-IN/register?ref=A80YTPZ1

Comments are closed.