How Much Does a 20’x20 Composite Deck Cost in 2025?

Composite decking project cost [2025 data]

$40-$80 per square foot installation cost

$5,750-$11,500 Average build cost (12’x12′)

$16,000-$32, 000 Average construction cost (20’x20′)

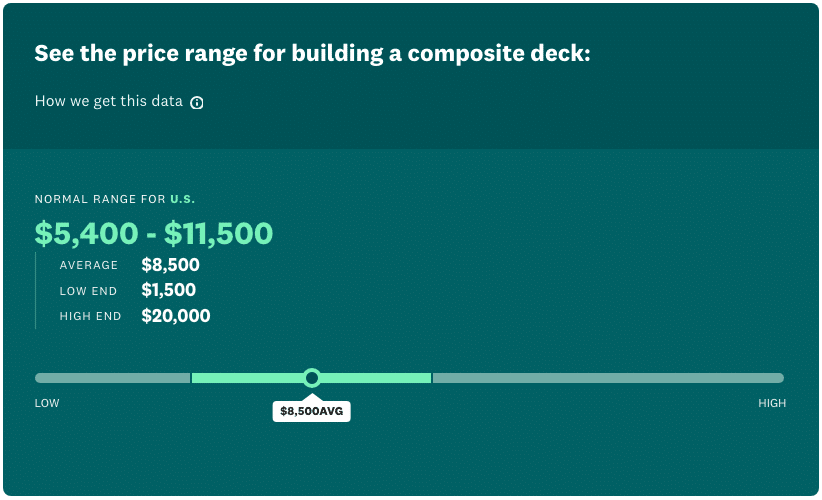

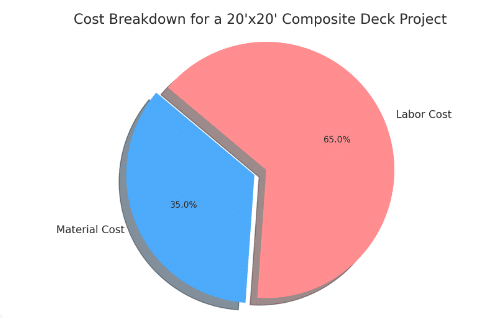

Typical costs for a composite deck range from $5,400 for a small area to $32,000 for a large deck project, with most owners choosing to install a composite deck project averaging $8,500. In fact, if you have higher quality requirements, your required budget will be higher, and labor costs will usually account for more than 65% of the cost of your composite deck project.

While enjoying summer barbecues and parties on the deck, relax on the comfortable, clean deck chairs and enjoy the perfect outdoor space. You’ll feel like the composite deck has changed your life and it’s all worth it.

This article will calculate the numbers for you so that you can choose your budget to enjoy the premium outdoor composite deck space.

Total cost and budget for the Composite deck (20'x20') project

The total cost of building a 20’x20′ (400 square feet) composite deck is about $16,000 to $32,000.

This is the sum of materials and labor costs, etc., which is the overall cost of the entire project, including materials, labor and substructure.

Table 1 shows the total cost comparison of the WPC deck material project:

| Item | Low-End Cost (USD) | High-End Cost (USD) |

| Material Cost | $6,400 | $12,800 |

| Labor Cost | $9,600 | $19,200 |

| Total Cost | $16,000 | $32,000 |

*If you plan to install a composite deck project, at least keep your budget within this range.

Here is a detailed cost analysis:

- Material cost:

Price: $16-$32 per square footMaterials typically account for 35% or less of the total cost. Material prices for composite decks vary by brand and quality (such as the market price of Trex or Ecoxplank or Fiberon), with material costs around $16 to $32 per square foot. Especially for the composite deck of the high-end product line.

Low-end material cost: 400 sqft x $16 = $6,400

High-end material cost: 400 sqft x $32 = $12,800

- Labor cost:

Price: $40-$80 per square foot

According to HomeGuide, labor accounts for 60% or more of the total cost, based on labor quotes from construction contractors. This range typically includes all labor and material costs for deck installation, with reference to the total cost of the actual project. Labor costs vary depending on the complexity of the project (such as design, additional features) and labor market prices in the region.

Total labor cost:

Low-end labor cost: 400 sqft x $24 = $9,600

High end labor cost: 400 sqft x $48 = $19,200

20’x20’WPC deck project cost pie chart:

The cost of composite deck

Installation costs of $40 to $80 per square foot per composite deck:

- Composites are priced from $16 to $32 per square foot.

- Labor costs for building composite decks are $24 to $48 per square foot.

Table 2 – Estimated Average Cost of various composite decks:

| Deck Size (ft) | Total Area (sq ft) | Total Cost Range (USD) | Material Cost Range (USD) | Labor Cost Range (USD) |

|---|---|---|---|---|

| 8×8 | 64 | $1,600 – $5,120 | $640 – $2,048 | $960 – $3,072 |

| 8×10 | 80 | $2,000 – $6,400 | $800 – $2,560 | $1,200 – $3,840 |

| 8×12 | 96 | $2,400 – $7,680 | $960 – $3,072 | $1,440 – $4,608 |

| 10×10 | 100 | $2,500 – $8,000 | $1,000 – $3,200 | $1,500 – $4,800 |

| 10×15 | 150 | $3,750 – $12,000 | $1,500 – $4,800 | $2,250 – $7,200 |

| 10×20 | 200 | $5,000 – $16,000 | $2,000 – $6,400 | $3,000 – $9,600 |

| 12×12 | 144 | $3,600 – $11,520 | $1,440 – $4,608 | $2,160 – $6,912 |

| 12×16 | 192 | $4,800 – $15,360 | $1,920 – $6,144 | $2,880 – $9,216 |

| 12×20 | 240 | $6,000 – $19,200 | $2,400 – $7,680 | $3,600 – $11,520 |

| 14×14 | 196 | $4,900 – $15,680 | $1,960 – $6,272 | $2,940 – $9,408 |

| 15×15 | 225 | $5,625 – $18,000 | $2,250 – $7,200 | $3,375 – $10,800 |

| 15×20 | 300 | $7,500 – $24,000 | $3,000 – $9,600 | $4,500 – $14,400 |

| 20×20 | 400 | $10,000 – $32,000 | $4,000 – $12,800 | $6,000 – $19,200 |

* Suitable for connecting ground and elevated composite decks

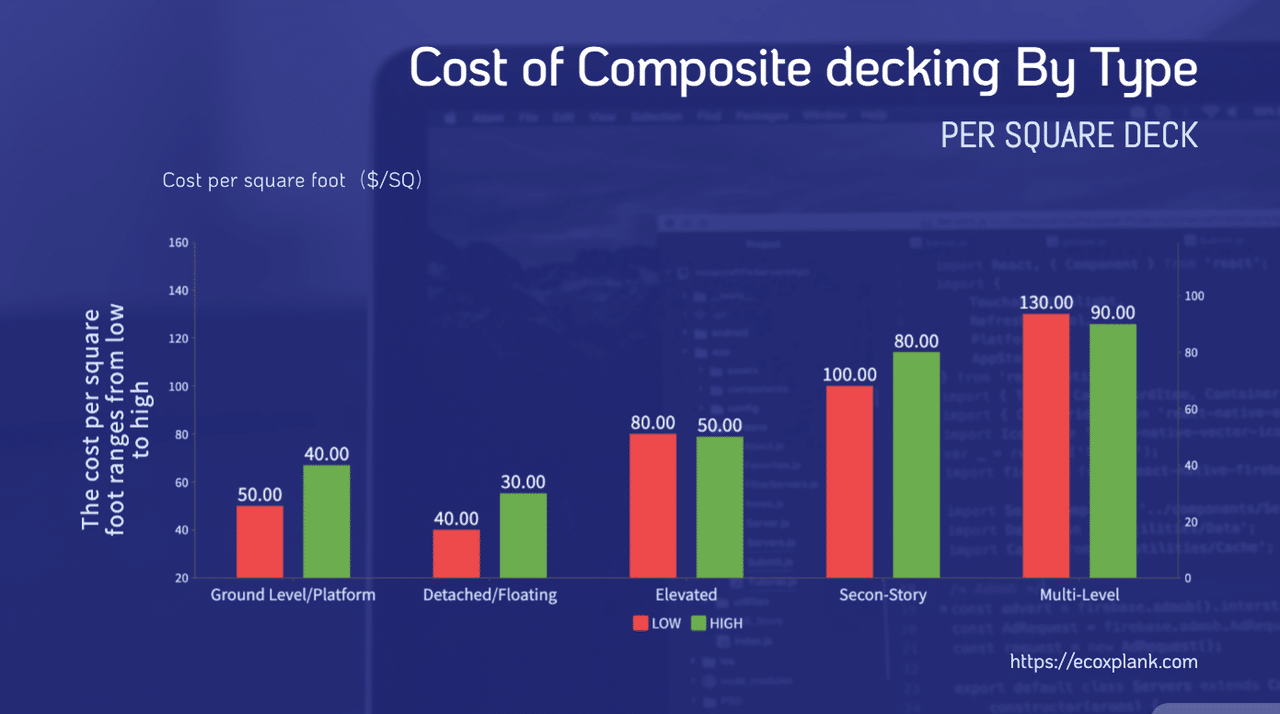

Different types of composite deck costs

Composite deck cost by type

| Deck Design Type | Installation Cost per Square Foot |

|---|---|

| Ground/Platform | $40–$50 |

| Detached/Floating (Standalone, No Rails, No Stairs) | $30–$40 |

| Elevated | $50–$80 |

| Second Story | $80–$100 |

| Multi-Level | $90–$130 |

* Price includes substructure and deck surface.

Composite WPC deck types Comparison table

| Deck Type | Key Features | Ideal Scenarios | Considerations |

| Ground-Level Deck | Height below 30-36 inches, simple design, optional railings. | Small backyards, budget-friendly projects, casual leisure spaces. | May require additional foundation for uneven ground; added steps or railings increase costs. |

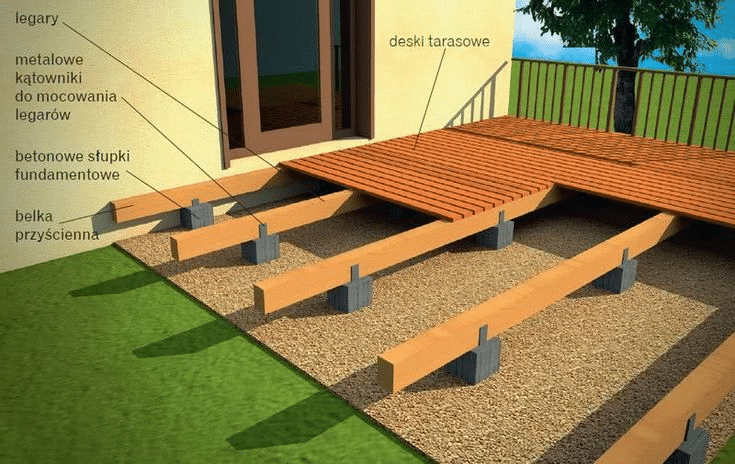

| Detached Deck | Not attached to the home, requires no railings, supported by gravel/concrete blocks. | Garden relaxation areas, flexible outdoor setups, low-budget installations. | Stability depends on gravel/concrete base; not suitable for extreme winds or soft ground. |

| Elevated Deck | At least 3 feet above ground, reinforced concrete base, requires railings. | Enhanced views, drainage avoidance, long-term structural stability. | Requires solid base; high views may block neighbor visibility, needs careful planning. |

| Second-Story Deck | Located outside the second story, creates a covered porch underneath, needs strong pillars. | Multi-story homes, additional shaded spaces, high-traffic areas. | Foundation strength and railing compliance with local codes; rainwater drainage required. |

| Multi-Level Deck | Most complex, multiple connected levels, separate zones for dining and lounging. | Luxury residences, maximized outdoor space, multi-functional zones. | Extended construction time; significant budget needed for structural supports. |

Factors affecting the cost of composite deck pavement

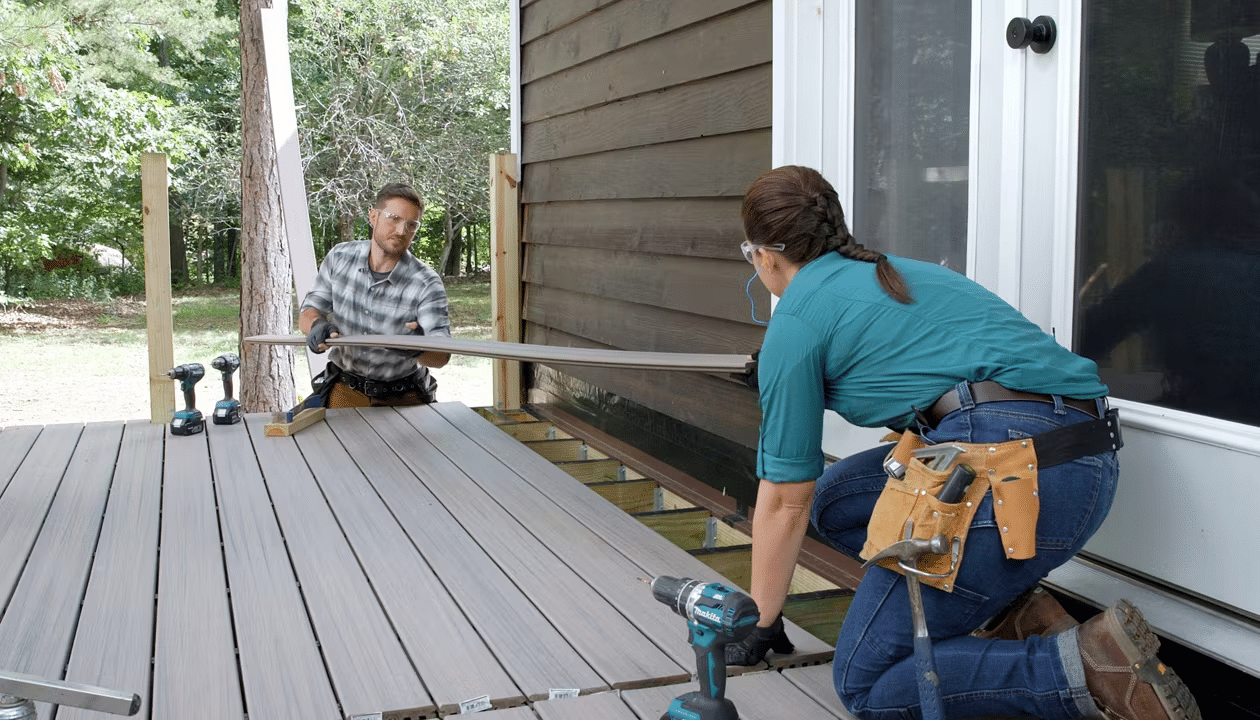

The labor cost of building a composite deck is higher than that of a wooden deck, because the composite requires additional parts to be assembled more carefully.

| Cost Factor | Cost per Square Foot | Description and Value |

|---|---|---|

| Material Cost | $15 – $30 | Material costs include composite decking, support systems, and fasteners. High-end materials offer better moisture resistance and UV protection. |

| Labor Cost | $20 – $45 | Professional installation ensures quality construction, including substructure assembly, decking installation, and fastener tightening. |

| Substructure and Support | $10 – $20 | Includes joist structures, support posts, and foundational materials to ensure the deck is stable and meets safety standards. |

| Additional Costs | $5 – $10 | Includes cleanup, waste removal, transportation, and tool rental fees. |

| Total Installation Cost | $40 – $75 | The total cost is below the market average, ensuring high cost-effectiveness and construction quality, with precise quotes based on actual project needs. |

Cost factors of WPC deck include:

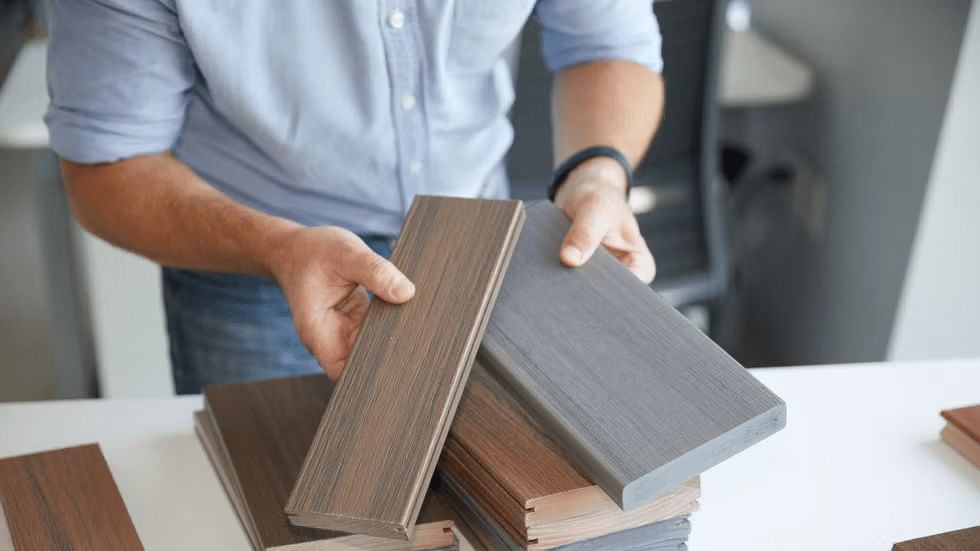

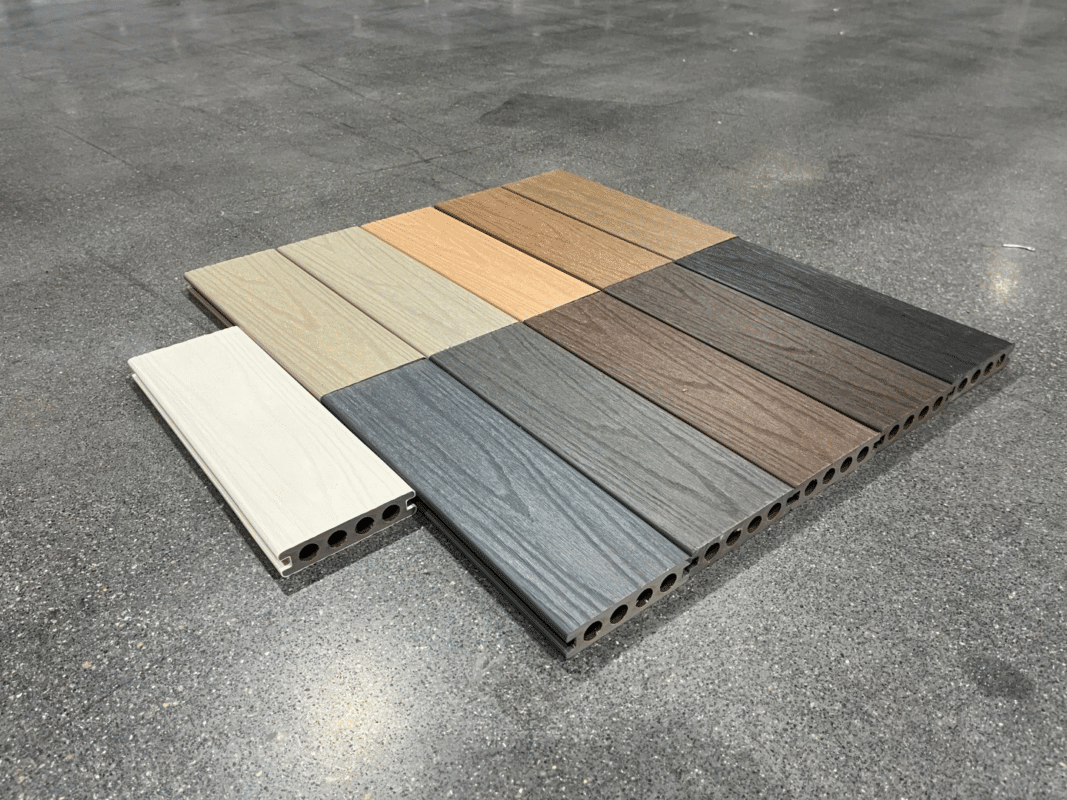

- Composite deck texture – Usually composite deck manufacturers will have a variety of colors to choose from without additional cost, but if it is a custom texture or complex design and wood texture, special abrasive tools are required to increase the cost.

The Ecoxplank manufacturer’s (ISO 9001 quality certified) deck costs nothing, and there is no additional cost for custom models.

- Covered and uncovered WPC deck – Covered composite is a co-extruded composite deck, that is, the surface has a layer of high-density protective coating, anti-slip, higher waterproof strength, so the cost will be higher than the uncovered deck cost. For ground decks or light structures, hollow panels are a cost-effective choice, and solid panels should be preferred for elevated or two-story decks to ensure safety and durability.

Cost variance:

Covered material: $25-$32/ sq ft

Materials without cover: $16-$20/ sq. ft

- Solid with hollow WPC board: Hollow composite deck suitable for light weight pressure, if in public places will cause deformation. Solid deck panels are dense and structurally robust, making them suitable for high-load applications (such as elevated decks), but at a higher price.

Cost variance:

Solid board: $20-$28/ sq ft

Hollow panel: $15-$22/ sq. ft

Fastener type – The hidden fasteners of today’s deck are more convenient and faster (refer to the best hidden firmware), and make the deck surface cleaner and safer. The cost of metal fasteners is higher than that of plastic fasteners, which can almost be ignored in the total cost.

Cost variance:

Traditional fasteners: $1-$2/ sq. ft

Hidden fasteners: $3-$5/ sq. ft

Foundation and drainage systems— in rainy areas, priority is given to installing drainage systems to protect deck structures.

Surface deck drainage system: Installation cost $1,000-$4,000, can effectively prevent moisture accumulation, avoid deck support structure rot.

Elevated deck drainage system: Increase the drainage and downpipe system under the deck, suitable for the second deck, the cost is higher.

Gravel base — Cost range: $0.85-$2.80 per square foot (including installation and material costs). Function: Prevent weed growth and promote rainwater drainage, suitable for elevated and second deck. Suitable for ground and elevated deck, long-term protection effect is good.

WPC deck foundation treatment in cold climates— Site survey before construction to accurately locate frost lines and reduce rework risks.

Concrete feet: In cold areas, support columns must be installed below the frost line to ensure structural stability and prevent foundation movement.

Cost impact: Increased excavation and concrete filling costs.

Add railings – Add wood railings or vinyl railings to the deck. It costs $20 to $60 per linear foot.

Installing stairs— Cost range: $20-$30/ linear feet (stairs themselves) + $80-$160 (concrete foundation). Length and complexity of stairs: Longer or guardrail stairs cost more. Purchase stairs together with deck materials to save transportation costs.

Foundation preparation and cost— Cost range: $500-$1,000 per yard/area.

Mainly affected by land smoothness slope, ground or soft soil areas need additional reinforcement and filling work. There are also support systems: elevated or two-story decks require additional concrete or steel support structures. It is recommended to hire a professional installation team for on-site investigation to reduce the cost of later changes.

- Geographical location and labor costs: Different geographical locations, labor costs are different, you can choose to flexibly choose the construction time, construction in the off-season with low labor costs (such as winter), while speeding up the construction progress.

Cost variance:

– Urban areas: Cost range: $50-$150 (depending on project size and regional policy).

– Rural areas: Low demand, low labor costs, about $20-$35/ hour.

- Permit fees and building regulations:

Cost range: $50-$150 (depending on project size and district policy).

Elevated or multi-deck decks require strict compliance with local building codes and permits must be applied for.

License fees and approval times vary by region. Check with local authorities in advance to find out what permits and regulations are required.

Prepare design drawings at the same time: Ensure that complete structural and safety assessment materials are submitted to speed up approval.

- Design and structural engineering costs:

Cost range: $100-$220/ hour (Structural engineer fee).

Design complexity: Multi-deck or curved, staircase designs require professional engineering evaluation.

Design drawings: Large areas or complex structures may require custom design, increasing design costs.

Optimized design requirements: on the premise of meeting the function, simplify the structure and reduce the workload of engineers.

Choose an experienced design team: complete the professional design once and avoid repeated modifications.

Custom features and add-ons Cost

- Comfort and entertainment features cost

| Function | Cost Range | Description and Value |

|---|---|---|

| Outdoor Furniture | $500 – $1,500/set | Purchase a high-quality set of outdoor furniture suitable for relaxation, gatherings, and dining scenes. |

| Outdoor Lighting | $80 – $300/light | Provides functional lighting and ambient illumination. LED lights are recommended for energy savings and extended lifespan. |

| Ceiling Fan | $150 – $400/unit | Install ceiling fans in shaded areas to ensure cool and comfortable air circulation. |

| Outdoor Outlets | $180 – $350/unit | Convenient for charging devices or connecting lighting, barbecue equipment, and other electrical appliances. |

| Hot Tub | $3,000 – $10,000 | Offers a luxurious outdoor relaxation experience. Installation costs range from $150 – $500. |

| Built-in Bench Seating | $1,000 – $1,500 | Aesthetic and practical seating option, saving space while providing additional storage functionality. |

- Shading and coverage options cost

| Function | Cost Range | Description and Value |

|---|---|---|

| Awning | $200 – $6,000 | Includes seasonal, manual, and retractable awnings, providing flexible shading solutions for decks. |

| Prefabricated Pergola (Partial Shade) | $1,450 – $5,570 | Simple structure providing partial shade, suitable for users with a moderate budget. |

| Deck Cover (Permanent Roof) | $10 – $60/sq ft | Based on materials (e.g., metal, PVC, or wood), it offers complete shading and protection functionality. |

| Permanent Patio Cover | $4,300 – $10,000 | Provides long-term protection, suitable for users requiring year-round deck usage. |

- Outdoor recreation and decoration function cost

| Function | Cost Range | Description and Value |

|---|---|---|

| Outdoor Fireplace | $1,500 – $9,000 | Provides warmth and a gathering center, ensuring compliance with local building codes for safety. |

| Outdoor Kitchen | $3,000 – $10,000 | Installs built-in grills and sinks to meet high-end outdoor cooking needs. |

| Concrete Walkway | $7 – $17/sq ft | Durable and practical walkway connecting the deck to the yard or garden. |

| Stone Walkway | $16 – $35/sq ft | Aesthetic and elegant walkway that enhances the overall luxury feel of outdoor design. |

- Custom design and professional support costs

| Function | Cost Range | Description and Value |

|---|---|---|

| Landscape Designer (Custom Service) | $50 – $100/hour | Professional designers provide customized solutions to maximize deck functionality and aesthetics. |

| Structural Engineer | $100 – $220/hour | Provides structural evaluations and professional design drawings to ensure large projects are safe and compliant. |

Prices of different types of composite flooring materials

The price of composite decks includes not only surface materials, but also additional costs such as lower structures, stairs, railings and fasteners.

The following are the base cost ranges:

- Composite deck material price: $4 – $16/ sq. ft.

- Substructure (support system) : $10 – $20/ sq. ft.

- Railing and stairs: $20 – $60/ linear feet.

Composite deck material prices by type

| Deck Type | Material Price per Square Foot | Features and Advantages | Suitable Scenarios |

| Polyethylene (PE/HDPE) | $3 – $11 | – Texture close to real wood, natural and aesthetic appearance. | Suitable for areas seeking a wood-like appearance, moderate budget, and limited sunlight. |

| – Easy to maintain but prone to heat retention under high temperatures. | |||

| – Surface is relatively susceptible to scratches and abrasions. | |||

| PVC (Polyvinyl Chloride) | $5 – $13 | – Wide range of colors, low maintenance cost, and good moisture resistance. | Suitable for users in humid environments and with low maintenance needs. |

| – Prone to swelling and shrinking; caution is advised in areas with large temperature differences. | |||

| – Susceptible to mold growth. | |||

| Polypropylene (PP) | $5 – $21 | – Surface offers a glossy effect, excellent high-temperature resistance. | Suitable for decks in extremely high-temperature regions and dry climates. |

| – Does not deform easily, but can become brittle in cold climates. |

How to choose a composite deck according to your needs?

1. The pursuit of authentic wood appearance:

- Recommended: Polyethylene (PE/HDPE) composite deck.

- Reason: Its texture is closest to natural wood, suitable for users who want to enhance the natural beauty of the courtyard.

- Note: Not recommended for exposure areas, easy to store heat.

2. Wet or rainy areas:

- Recommended: PVC composite deck.

- Reason: PVC material has good moisture resistance, easy to clean and not easy to deformation.

- Note: Check for mold growth regularly, especially in poorly ventilated areas.

3. Extreme heat or sun areas:

- Recommended: Polypropylene (PP) composite deck.

- Reason: PP material has excellent high temperature resistance, the surface will not be deformed or faded due to high temperature.

- Note: Not suitable for long-term low temperature

Comprehensive analysis of composite deck brand price and characteristics

Price of laminate flooring by brand

This table is for brands of composite deck materials, of which Ecoxplank is the source deck manufacturer.

| Brand | Material Price per Square Foot | Features and Advantages | Suitable Scenarios |

| Ecoplank | $1.28 – $1.61 | Factory-direct sales, no middleman price difference, high cost-effectiveness, economical. OEM manufacturer for major brands. | Suitable for large projects, direct export pricing, focusing on stable quality. |

| Berg | $7 – $9 | Mid-range price, excellent value for money. High material quality, easy maintenance, suitable for most climates. | Suitable for mid-range budgets and households focusing on design aesthetics. |

| Decorators | $5 – $9 | Offers a variety of color and texture options with an attractive appearance. Low maintenance cost, long-term durability. | Suitable for users seeking cost-effectiveness and diverse choices. |

| Envision | $5 – $16 | Covers the premium market, providing superior wood texture. Adapts well to hot and humid climates. | Suitable for users demanding high-quality, high-performance outdoor spaces. |

| Fiberon | $7 – $14 | Industry leader; materials offer excellent anti-scratch properties. Provides long-term warranty services. | Suitable for the premium market and projects with higher quality requirements. |

| Genovations | $4 – $7 | Low price, lightweight, and easy to install. | Suitable for projects with limited budgets and basic functional design. |

| Moosewood | $6 – $12 | Offers strong water resistance and durability for long-term use. Adapts to high-temperature environments. | Suitable for coastal and humid environments. |

| Sun Deck | $3 – $8 | Budget-friendly option, lightweight, and easy to install. Low maintenance cost. | Suitable for low-budget, simple outdoor decking projects. |

| TimberTech | $6 – $13 | Rich wood grain appearance with excellent durability. Provides long-term warranty services with high customer satisfaction. | Suitable for general applications, targeting users with long-term durability needs. |

| Trex Decking | $5 – $15 | Industry leader, premium material production, low maintenance costs. Provides multiple product tier options. | Suitable for high-end applications, users seeking branded and durable products. |

Composite vs. Wood floor construction costs

If you are considering the long-term value of a deck, you must choose a WPC deck.

Composite decks initially cost $40 to $80 per square foot to install, and wooden decks cost $25 to $50 per square foot. But we can’t just look at the initial cost, we have to look at the service life and maintenance costs to make a comprehensive comparison.

Composite Decking

| Feature | Description and Advantages |

|---|---|

| Installation Cost | The installation cost per square foot is $40 – $80. While the initial cost is relatively high, composite decking requires minimal maintenance, significantly reducing long-term costs. |

| Lifespan | The lifespan reaches 25 – 50 years, with no need for replacement or resealing. |

| Maintenance Requirements | Low maintenance: no need for polishing, staining, or anti-rot treatment, requiring only periodic cleaning to maintain its appearance. |

| Appearance Options | Offers a variety of colors and textures, with a wood-like appearance suitable for various design needs. |

| Durability | Resistant to corrosion, moisture, and cracking, making it ideal for outdoor environments with high humidity or extreme temperatures. |

| Color Stability | Difficult to repaint, but the color remains long-lasting and does not easily fade. |

Wood Decking

| Feature | Description and Advantages |

|---|---|

| Installation Cost | The installation cost per square foot is $25 – $50, with relatively low initial investment. |

| Lifespan | The lifespan is 5 – 15 years, depending on maintenance frequency and material type. |

| Maintenance Requirements | Requires regular maintenance, including polishing, staining, and waterproof sealing, leading to higher long-term costs. |

| Appearance Options | Natural wood appearance with a warm texture; colors can be changed through staining or oiling. |

| Durability | Prone to cracking, warping, and rotting, especially in high-humidity or extreme climates. |

| Long-term Cost | Maintenance costs increase over time, and board replacement may be necessary. |

The advantages and disadvantages of composite deck and wooden deck

| Comparison Factors | Composite Decking | Wood Decking |

|---|---|---|

| Initial Installation Cost | $40 – $80/sq ft | $25 – $50/sq ft |

| Long-term Maintenance Cost | Extremely low, only requires cleaning | High, requires regular polishing, sealing, and staining |

| Lifespan | 25 – 50 years | 5 – 15 years |

| Durability | Resistant to rot, moisture, and UV rays | Prone to rot, cracking, and insect damage |

| Maintenance Requirements | No additional maintenance required | Requires frequent maintenance |

| Appearance and Color | Realistic wood-like appearance, stable color retention | Natural wood grain, color can be changed |

How to choose the right deck for you?

1. Budget and long-term costs:

- If initial costs are important, wooden decks are an affordable option.

- If the pursuit of low maintenance and long-term savings, composite deck is more cost-effective, is the most ideal choice.

2. Maintenance requirements:

- Users who do not want to invest maintenance time are advised to choose composite decks.

- If you like DIY maintenance and wood texture, wood deck is more suitable.

3. Climate and Environment:

- In areas of high humidity or extreme climates, composite decks perform better, resist rot and moisture and last longer.

- Wooden decks are more suitable for mild and dry climates.

Although the initial installation costs of the WPC deck are higher, its low maintenance requirements, extremely long service life and durability make it the first choice for modern home and commercial projects.

Wooden decks are suitable for users with a limited budget and a preference for natural texture, but require time and money to invest in long-term maintenance.

FAQ about laminate flooring

What is composite decking?

Laminate flooring is an environmentally friendly material that combines wood fiber with recycled plastic and is designed to replace traditional wooden decks. It combines the beauty of natural wood with the high durability of plastic, is resistant to moisture, rot and pests, and does not crack or deform easily.

The core advantages of laminate flooring are its low maintenance costs and long service life, making it ideal for outdoor terraces, pool decks and commercial Spaces.

Can you brad nail composite decking?

Nails (such as fine nails) cannot be used to fix composite decks because they do not have enough holding power, are prone to bending or breaking, and cannot effectively withstand the weight and environmental changes of the deck.

Instead, it is recommended to use specially designed deck hiding firmware screws that have better holding force to secure the screws to the hiding firmware and nail them into the keel of the deck and better accommodate the expansion and contraction of the composite material, ensuring the safety and durability of the deck. It can be used for decades without screws loosening.

How to clean composite decking?

Composite decks require almost no complex cleaning, just ordinary surface cleaning and water gun flushing, or you can follow our detailed composite deck cleaning process.

Regular cleaning: To clean a composite deck, first empty the deck of furniture and items, and then use a broom to sweep away loose dust and debris. Next, rinse the deck surface with warm water to better remove dirt. Then, mix warm water and mild dish soap in a bucket and use a soft brush to gently scrub the deck, making sure to clean along the grain to avoid scratching the surface.

For stubborn stains, a mixture of vinegar and water can be applied topically. Finally, rinse the deck thoroughly with water to ensure there is no residual soap and dirt to keep its appearance fresh.

How long does composite decking last?

Composite decks typically have a service life of between 25 and 50 years, depending on the quality and maintenance of the material. High quality composite decks, when properly maintained, are resistant to decay, deformation and insect infestation, far exceeding the 5 to 15 year service life of traditional wooden decks.

Manufacturers like the Trex even offer up to 50 year warranties, further proving its durability and low maintenance needs.

Can you stain composite decking?

Ecoxplank is a famous professional deck manufacturer in China, we very much do not recommend to paint the composite deck, but this mainly depends on the type of deck. For older, unclad composite decks, coloring can be used. However, modern composite decks have PE cladding, a design that does not allow the stain to adhere effectively, and attempting to stain may void the warranty.

If you do plan to dye, it is recommended to use products designed for composite materials, such as ZAR Deck & Siding Solid Color Coating, which provide good adhesion and durability. Make sure to clean the deck thoroughly before dyeing for best results.

How to install hidden fasteners on composite decking?

To install concealed fasteners on the composite board, all necessary materials should be gathered at the beginning, including the composite board, concealed fasteners, starting clips, and standard woodworking tools.

See how to install hidden firmware.

Is composite decking slippery?

Not really. Much depends on the type of composite deck. Older generations with smooth surfaces are more likely to become smooth due to moisture, algae, and mold buildup, which can create dangerous conditions.

In contrast, second-generation composite paving products typically have textured surfaces and anti-slip properties that enhance grip and reduce slippage even in wet conditions. Ecoxplank has developed a third generation rubber coating, which is highly resistant to slip, and the wood grain is more realistic and durable.

Do you need a special blade to cut composite decking?

Yes, you need a special saw blade to cut laminate flooring effectively. It is recommended to use a fine-toothed hard diamond saw blade, especially one with about 80 teeth, as this type provides a good balance of speed and accuracy while minimizing splitting.

A circular or miter saw is the ideal tool for this task, and the use of a blade designed for composite materials ensures a clean and precise cut. In addition, Ecoxplank manufacturers recommend using a specific size of blade with a dense number of teeth to achieve smooth cutting without damaging the material (for cutting sections over 20cm, Ecoxplank will use a PCD diamond saw blade with 120 teeth at a cost of $630 per piece).

Will composite materials increase home values?

Yes, installing a composite deck can significantly increase the resale value of a home and is a high-return investment. According to the latest market data, the return on investment of composite deck projects is as high as 85%, and the average value of the home is about $15,000.

About hiring a deck contractor

When choosing a deck installation team, Avoid the underquote trap:

Often they use low-quality materials, hide extra costs during construction, or have workers who lack professional skills, leading to rework or delays. Be sure to follow these steps:

Step 1: Select the right composite deck installer

- Get multiple quotes: Compare at least 3 different contractors to ensure prices are transparent and reasonable.

- Verification of qualifications and licenses:

– Contractor’s license and proof of insurance (business liability insurance and workers’ compensation insurance).

– Manufacturer’s authorized installation certificate.

– Relevant Association certification (e.g., North American Deck and Railing Association). - Past Project references: Ask to see photos of past composite deck projects completed by the contractor to ensure the style meets your needs.

- Customer reviews and word of mouth: Check out real user reviews on Google, Yelp, HomeGuide, etc., to understand the quality and reliability of their work.

- Provide a list of references: The contractor is required to provide at least 3 references from previous clients for further verification.

Step 2: Key questions to ask before hiring

- When communicating with the deck installation team, the following issues should not be ignored to ensure a smooth project and avoid hidden costs:

1. Company qualification and experience

– How long have you been in the composite decking business?

– Do you have relevant licenses, insurance and installation certificates?

2. Project plan and design

– Can you provide photos or examples of past projects?

– Which designs and materials best suit my family’s needs and budget?

– Does the installation process require a license? Can you help with the application?

3. Project time and cost

– What is the detailed project start and completion time?

– Are there any unexpected charges? If so, how to deal with it?

– Does the quotation include: materials, labor, structural support, cleaning and garbage removal?

4. Installation quality and warranty

– Do you offer installation quality assurance? How long is the warranty period?

– Does the material used have a manufacturer’s warranty?

– If there is a problem, how to solve the after-sales service?

5. Team and management

– Who will supervise the construction during the project?

– How many workers are on your team? How long is the working day?

– How do you manage site safety and construction quality?

3 thoughts on “How Much Does a 20’x20 Composite Deck Cost in 2025?”

Okay, s666fyford. I would recommend it! And it’s very easy to navigate, and it’s very fast. Check it out for yourself: s666fyford.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Heard some buzz about 888jogobet. Anyone played there? How’s the gaming experience? Is it worth checking out? See for yourself: 888jogobet

Comments are closed.