How to Lay Composite Deck Joist?

[seopress_breadcrumbs]

Composite deck joists are the core foundation supporting the deck. The right materials and installation can make the deck more stable, durable and beautiful to look at.

composite joists are the perfect alternative to traditional wood or metal joists and are favored for their superior durability, water resistance and maintenance-free properties.

This article will serve as a comprehensive guide detailing how to properly lay composite deck joists. Whether you are an experienced decorator or a beginner, we will provide practical steps and tips. You’ll learn the benefits of composite joists, installation methods, and maintenance recommendations to ensure your deck project is completed successfully.

What are Composite Deck Joists?

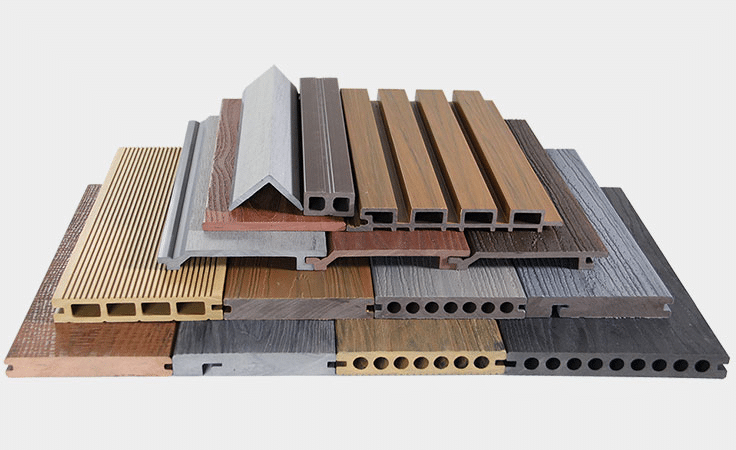

Composite deck board joists are structural components specifically designed to support composite decking boards. They are made from a blend of recycled materials such as plastic and wood fibers.

Compared to traditional wood or metal joists, composite deck joists offer superior resistance to rot, warping, and cracking. They are also highly resistant to moisture and insect damage, making them durable and low-maintenance, which makes them an excellent alternative to traditional wood or metal joists.

Composite deck joists are engineered for performance, featuring lightweight, corrosion-resistant, and sustainable properties. Manufactured with advanced material technology and tested to meet ASTM D7032 standards, they exhibit a water absorption rate of less than 1% and a lifespan of up to 25 years with proper maintenance.

This makes them an ideal choice for outdoor decking projects, as they provide a sturdy foundation capable of withstanding various weather conditions, including high humidity and temperature fluctuations. Their lightweight design is approximately 30% lighter than traditional wood joists, making installation significantly easier. Furthermore, their environmentally friendly composition helps reduce carbon footprints, aligning perfectly with modern environmental goals.

Composite Deck Joists vs. Traditional Joists

Composite joists for decking show significant advantages over traditional wood or metal joists in several ways.

- Comparison with wood joists:

Composite timber joists are susceptible to moisture and pests and can rot, deform, or even lose structural strength over time, resulting in frequent, high-cost maintenance. The composite joists have excellent moisture-proof and insect-proof properties, and can resist warping and maintain long-term stability. In addition, composite joists do not need to be regularly sealed or dyed like wood joists, requiring minimal cleaning and maintenance, greatly reducing maintenance costs.

- Comparison with metal joists:

Compared to heavy and corrosion-prone metal joists, composite decking bearers are lighter in weight, more flexible in design, and have a greater span capability for easy operation and installation. In addition, the composite joists do not rust from exposure to moisture or salt spray, and their structural integrity is able to withstand harsh weather conditions for many years. Although the initial cost of composite joists may be slightly higher, in the long run, it offers significant cost performance due to lower maintenance requirements and longer service life.

- Made from recycled materials, the composite joists not only reduce reliance on natural resources, but also avoid the deforestation problems that traditional wood can involve. Its environmental nature makes it ideal for green buildings and sustainable development.According to research data, the service life of composite joists is 20-25 years, while wood joists are only 10-15 years, and metal joists require frequent anti-corrosion treatment. In addition, a case study showed that composite joists in high-humidity environments reduced maintenance costs by about 40% over 10 years compared to wood joists.

Cost durability comparison table of the three joists:

Feature Composite Joist Wood Joist Metal Joist Weight Approx. 1.5 kg per meter Approx. 2.8 kg per meter Approx. 7 kg per meter Lifespan 20-25 years 10-15 years 30+ years Maintenance Clean once p Apply anti-corrosion treatment annually Frequent anti-corrosion and rust treatments required Environmental Impact High, made from recycled materials Moderate, may involve deforestation Low, but high emissions during manufacturing

What best Joists are Used for Composite Decking?

The best joists for composite decks are usually composite joists or treated metal joists because these two materials have excellent durability and are extremely compatible with composite panels. The selection of the appropriate joist material needs to be considered according to the specific location of the deck, load requirements and environmental conditions. Here is an analysis of the most common joist options: composite joists, metal joists.

- Composite joist: the choice of environmental protection,

low maintenance and ultra-high durability

Composite joists are made from a mixture of wood fiber and plastic, similar to composite deck materials. These joists have the following characteristics:

- Highly resistant to rot, moisture and pests: making it ideal for outdoor applications. Especially suitable for outdoor environments with high humidity or frequent rainfall.

- Environmental features: Made of recycled materials and compliant with green building standards.

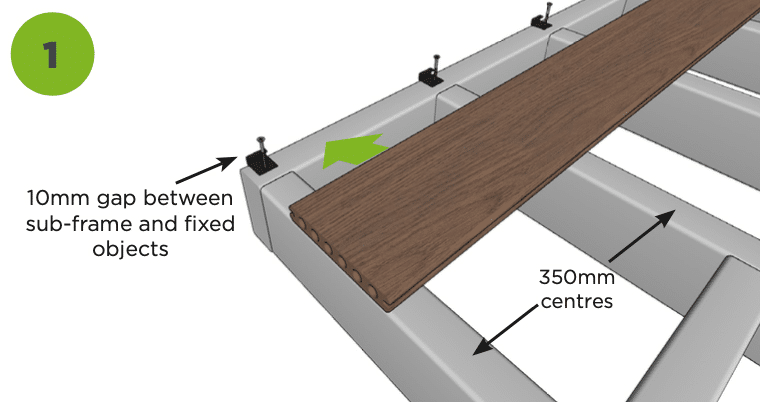

- Easy maintenance: no frequent handling required, only basic cleaning is needed to maintain performance.However, because the strength of composite joists is slightly lower than that of metal joists, smaller spacing supports (e.g. 350 mm) are usually required. Composite joists are more suitable for projects with low maintenance, low cost and higher demand for environmental protection.

- Metal joists: the choice of high strength and durability

Metal joists, such as aluminum or galvanized steel, are another recommended option due to their superior strength and corrosion resistance, especially when load-bearing requirements are high.

- High strength: Suitable for large or elevated deck projects, providing longer span support.

- Strong durability: no rust or warping, able to maintain structural integrity in extreme weather conditions.

- Long life: it can usually be used for more than 30 years, but for those without anti-corrosion treatment, frequent maintenance is required.Although the initial cost of metal joists is high, their long life and reliability make them the first choice for high-budget projects.

In Summary:

If the project is environmentally friendly and low cost, low maintenance needs are higher, and the budget is moderate, it is recommended to choose composite joists. Composite joists offer significant advantages in terms of daily maintenance and environmental friendliness, making them ideal for home and commercial projects and outdoor decks.

For decks with higher load-bearing requirements or for use in extreme weather conditions, metal joists are a more robust choice, especially in elevated or commercial projects. Despite the large initial investment, the long life value of the metal joists can save long-term costs for the project.

Key Considerations Before Installing Composite Deck Joists:What You Need to Know?

Before installing composite deck joists, carefully plan the joist spacing, ground clearance, and joist thickness. These key factors directly affect the structural stability, durability and overall experience of the deck. Here’s a detailed guide:

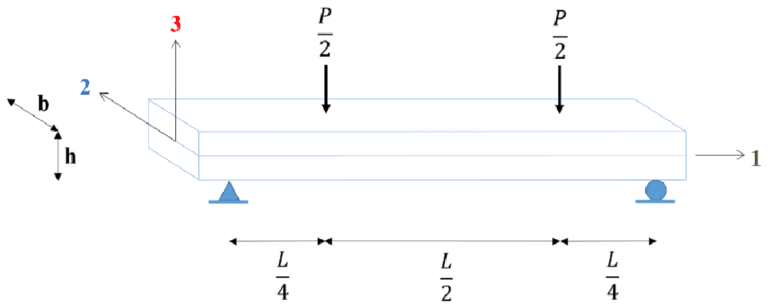

A. What is Correct Joist Spacing for Composite Decking?

The standard pitch for composite deck joists is usually 30 cm to 40 cm (12 in to 16 in) center pitch, depending on the following factors:

- Deck material properties: Different composite decks may have different requirements for support spacing.

- Usage scenario: The load requirements for residential and commercial use are quite different.

- Manufacturer’s advice: Always refer to the deck manufacturer’s specific installation guidelines.

Residential use:

For ordinary residential decks, 16 inch (40 cm) center spacing is a common standard, providing adequate support and stability.

Commercial use or high load areas:

For commercial projects or high-flow areas that require greater loads, it is recommended to reduce the spacing to 12 inches (30 cm) to enhance carrying capacity and prevent deck sinking or deformation.

Notes for special projects:

In projects with large span areas or high load requirements, denser spacing should be selected to enhance structural strength. Prior to installation, it is recommended to evaluate the joist design according to ASTM D7032 or the load calculation guidelines provided by the manufacturer to ensure that the joist design meets the project requirements.

Through reasonable joist spacing design, it can not only improve the stability and safety of the deck, but also extend its service life and avoid frequent maintenance and replacement.

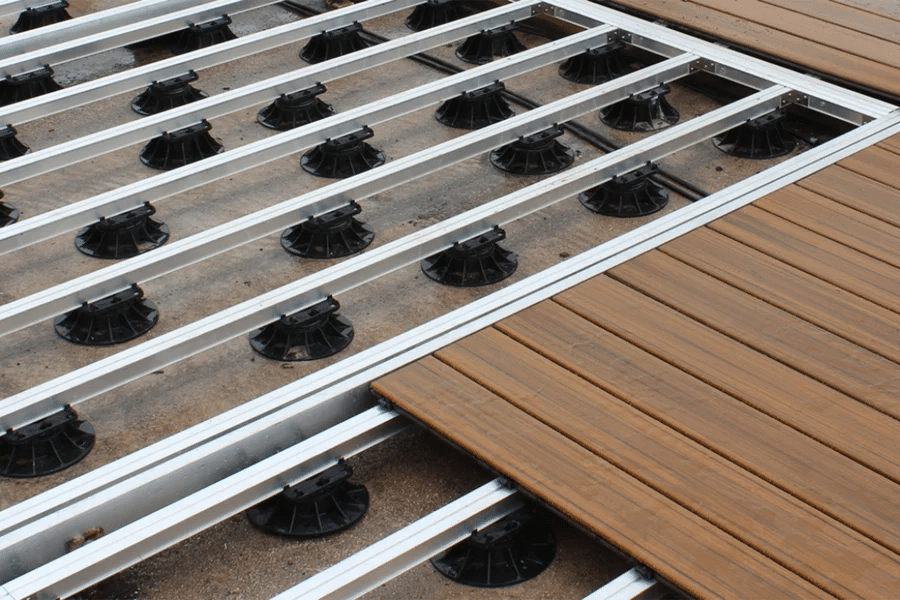

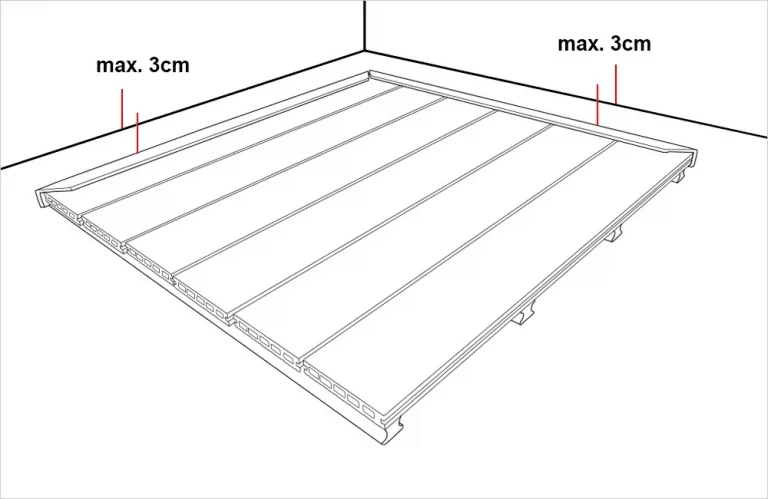

B. Ground Clearance and Composite Joist Height

Here are some best practice suggestions:

- Minimum ground spacing:

- Joists should be kept at least 12 inches (30 cm) away from the deck to prevent moisture buildup, mold growth, and corrosion.

- Where space is limited, the floor spacing should not be less than 6 inches (15 cm), while ensuring good ventilation conditions under the joists.

- Elevated deck:Elevated decks often require higher joist designs to enhance structural support. When installing elevated decks, it is recommended to select joists of higher specifications according to load requirements, while strengthening the connections between joists.

- Ground deck:Due to the proximity of ground decks to the ground, special attention should be paid to drainage and ventilation design. For example:

- In areas with poor drainage conditions, anti-moisture MATS can be laid or joists can be treated with special coatings to reduce moisture damage.

- By optimizing joist height and ground spacing, the deck’s moisture resistance and long-term stability can be significantly improved.

C. Joist Thickness

Joist thickness is one of the core parameters that affect deck load capacity and structural strength. The following are common joist sizes and application scenarios:

- Standard size:Common joist specifications include low profile 2×6, 2×8 and 2×10, which are typically 50 mm thick. These sizes meet the basic needs of most home deck projects.

- High load area:In areas with high load requirements or large spans, thicker joists (such as 2×8 or 2×10) are recommended. Thicker joists not only provide greater support, but also reduce joist spacing, thereby enhancing the overall stability of the deck.

- Light load area:In areas with low frequency of use or light load (such as decorative decks), standard thickness joists can meet support needs.

How to Install Composite Deck Joists (Step-by-Step)

Installing composite joists is a key step in ensuring the structural stability and durability of composite deck projects. We have arranged the installation videos of wood, metal and Composite Deck Joists for you respectively, for your reference according to your own needs:

Metal joist installation video

Composite Deck Joists installation video

Wooden Joists installation video

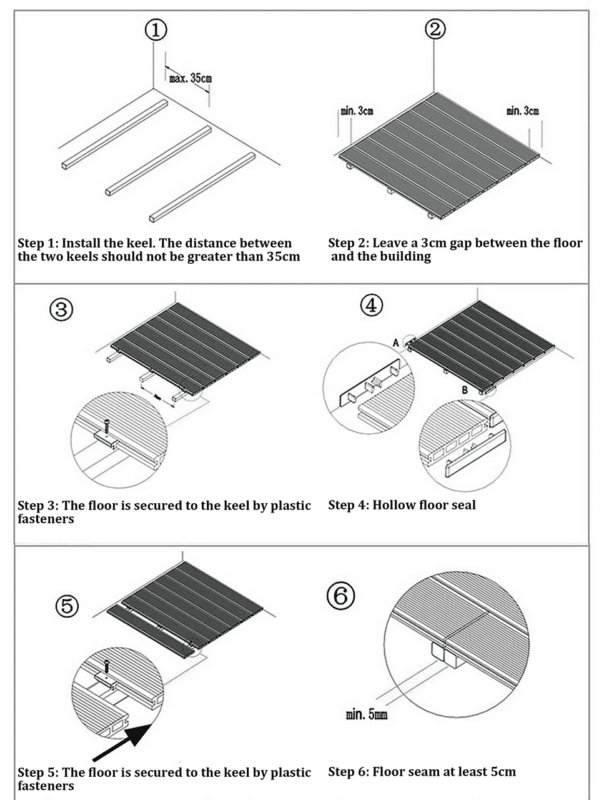

The following is a step-by-step guide based on industry best practices and authoritative standards such as ASTM D7032:

A. Preparation: Preparation Work

Before formal installation, adequate preparations must be made to ensure that the construction goes smoothly:

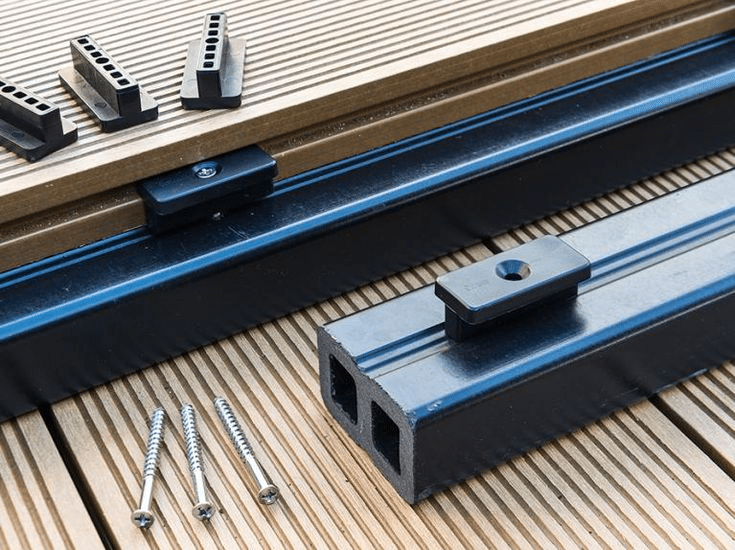

- List of tools and materials:

- Tools: level, electric drill, ruler, saw, screwdriver, protective gloves.

- Materials: composite joists, joist hangers, anti-corrosion coating, fixing screws, deck post bases.

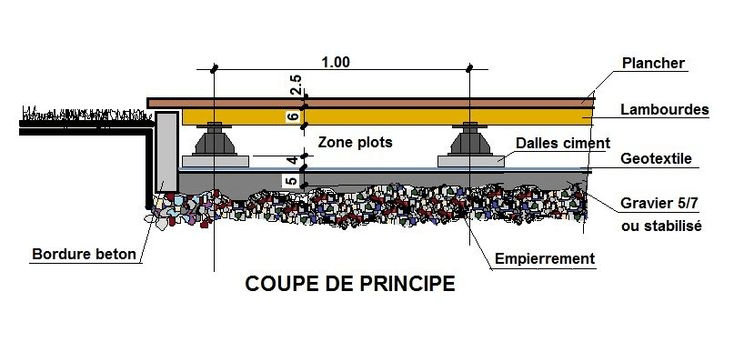

- Check the foundation:

- Ensure that the foundation is smooth and strong. If the foundation is soft or poorly drained, it is recommended to lay sand and gravel foundation or concrete cushion.

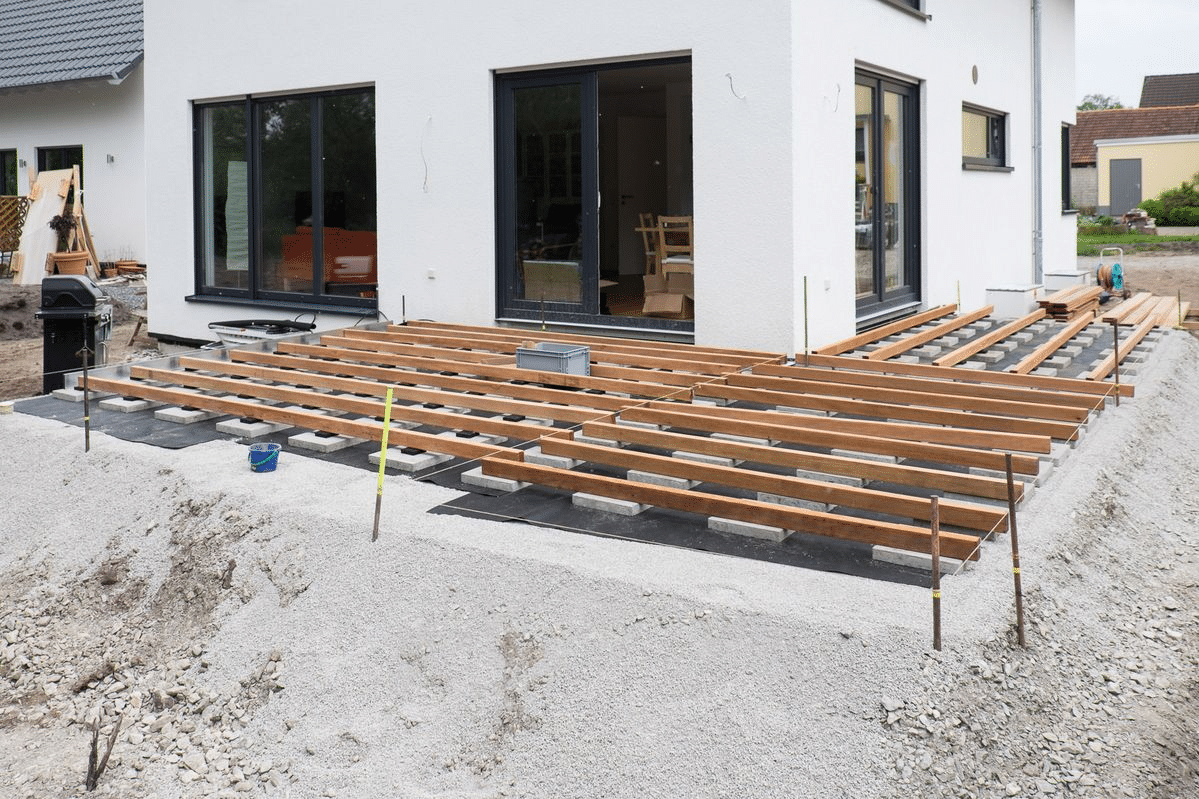

- Planning Joist Layout:

1. Mark joist spacing and orientation according to deck design requirements. Residential decks typically feature 16 inch (40 cm) center spacing, while high load areas are recommended to be reduced to 12 inches (30 cm).

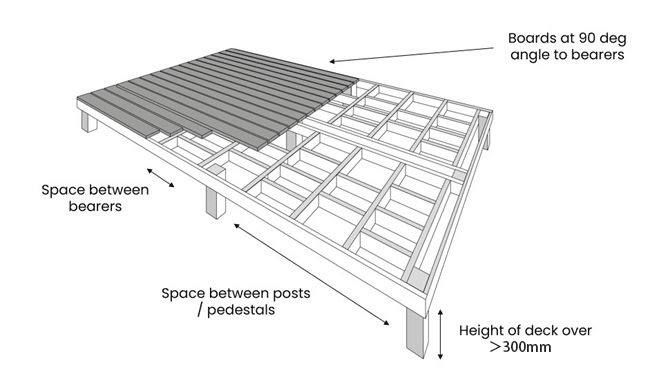

B. Step-by-Step Installation Guide

Step 1: Prepare the Base

- Lay a grass cloth on the ground to prevent the impact of plant growth on the joist structure.

- If the deck is designed to be elevated, use a concrete base to secure the pillars and ensure good drainage.

Step 2: Install the Ledger Board

- Secure the main beam to the house or other fixed structure to ensure its level.

- Use high-strength bolts (lag bolts) to secure the main beam firmly, and apply waterproof sealant around the bolts to prevent water intrusion.

Step 3: Place and Secure Joist Hangers

- Install joist pendants at intervals along the main beams, as determined by deck design requirements (e.g. 16 “or 12”).

- Ensure that joist pendants are aligned horizontally and secured with galvanized screws to enhance corrosion resistance.

Step 4: Lay the Joists

- Place the joist in the pendant, ensuring that its ends are securely connected to the pendant and the main beam.

- Use a level to check whether the joists are flat and adjust the joist height to ensure that the deck surface is not uneven.

Step 5: Add Blocking and Rim Joists

- Add blocking blocks between joists, especially in high load areas, to reduce lateral movement of joists.

- Install rim joists (rim joists) to seal and reinforce the entire frame.

Step 6: Check Alignment and Fix Any Issues

- Recheck the alignment of all joists to ensure there is no tilt or loosening.

- Tighten all screws, pendants and connectors to ensure the frame is secure and reliable.

C. Common Mistakes to Avoid

- Joist spacing is too large: too much spacing will cause the deck surface to sink or deformation, should strictly follow the 16 inch or 12 inch spacing standard.

- Uneven foundation: Uneven foundation will cause the joist frame to tilt, and the foundation condition should be carefully checked before installation.

- Use the wrong fasteners: It is recommended to use anti-corrosion galvanized screws or stainless steel screws to extend the service life.

- Ignore ventilation design: Insufficient ventilation between the joist and the ground will accelerate the accumulation of moisture, and sufficient air circulation space should be ensured.

Summary: The Key to a Successful Installation

Prior to construction, consult the manufacturer’s installation guidelines and relevant industry standards (such as ASTM D7032) to ensure that the project meets requirements. By following the step-by-step guidelines above and paying attention to common construction problems, you can ensure that the composite joists are installed to the best possible effect.

Properly installed joists not only provide solid support for the composite deck, but also extend the service life of the deck.

Your Trusted Partner for Composite Deck Joists

As an expert in composite joist exports, Ecoxplank delivers high-quality composite joist products that not only meet international environmental standards, but also pass a number of corrosion resistance and load-bearing performance tests to ensure excellent structural integrity in all types of adverse weather conditions.

Choose Ecoxplank and you will enjoy the following advantages:

- Excellent quality: Products are ASTM D7032 and other industry standards to provide durable joist products.

- Environmental commitment: Use recycled materials to help green buildings and reduce their carbon footprint.

Technical support: Ecoxplank offers professional installation guides and technical advice to help you complete your deck project with ease.

- Customized services: Whatever your WPC project needs, Ecoxplank offers a personalized solution.

If you are looking for high performance composite joists, Ecoxpplank will be your ideal partner. With us, you can not only complete a high-quality deck project, but also contribute to the environmental cause. Contact us today for more product details and technical support!

FAQ:

Common Mistakes to Avoid

The choice of 4×2 or 6×2 joists depends on the design requirements and load capacity of the deck:

- 4×2 joists are suitable for light load deck projects such as small courtyards or decorative platforms. Due to their smaller thickness, smaller joist spacing (e.g. 12 inches) is usually required to ensure structural stability.

- 6×2 joists are suitable for larger spans and heavy load areas, such as large residential decks or elevated decks. They provide greater support and reduce the number and spacing of joists required. Recommendation: If the deck has a large span or needs to carry heavy furniture and high human traffic, the 6×2 joists are preferred to ensure safety and durability.

What Is the Service Life of Composite Deck Joists?

Composite joists typically have a service life of 20 to 25 years, depending on the use environment and maintenance conditions:

- Corrosion resistance: Composite joists are resistant to rot, moisture and pests, especially suitable for wet or rainy environments.

- Low maintenance requirements: Compared to wood joists, composite joists do not require regular sealing or staining, and only basic cleaning is required to maintain performance. Note: Ensure that joists are spaced and ventilated in accordance with manufacturer recommendations to further extend their service life.

Can Composite Joists Be Used for Elevated Decks?

Yes, composite joists can be used for elevated decks, provided the following conditions are met:

- Load requirements: Composite joists are usually used for elevated decks with moderate loads. If you need to carry a higher weight, you can narrow the joist spacing or use metal joists.

- Support structure: It is recommended to use high-quality base brackets and connectors to ensure the stability and safety of the entire elevated frame. Summary: Composite joists are ideal for elevated decks, especially in low-maintenance and environmentally demanding projects.

Are Composite Joists Suitable for All Climates?

Composite joists are designed to perform well in a variety of climatic conditions, including:

- High humidity environment: The composite joists have excellent moisture resistance and will not rot or warp due to moisture.

- Cold climate: Low water absorption reduces the risk of freezing at low temperatures.

- High temperature area: has a low coefficient of thermal expansion, suitable for large temperature difference environments. Note: In extreme weather conditions, ensure that the manufacturer’s installation guidelines are followed to maintain joist performance.

What Is the Cost Difference Between Composite Joists and Conventional Joists?

- Initial cost: The initial cost of composite joists is usually about 20-30% higher than that of wood joists, but lower than that of metal joists.

- Long-term cost: The low maintenance requirements and longer service life of composite joists make them a more economical option. For example, compared to wood joists, composite joists can save about 40% in maintenance costs over 10 years. Summary: Although the initial investment is slightly higher, the composite joists have significant advantages in service life and maintenance costs, and are suitable for long-term investment.

Can You Put Composite Decking on Wooden Joists?

- Yes, WPC decking can be installed on wood joists, but the following points need to be noted:

- Quality of wood joists: Ensure that wood joists are pressure treated wood and are treated with preservatives to avoid rot and pests.

- Installation conditions: The composite deck boards spacing must be arranged strictly according to the requirements of the Composite fool (usually 16 inches or 12 inches). Note: If the deck project is located in a high humidity or wet area, it is recommended to prioritize composite or metal joists to reduce long-term maintenance requirements.

Get A Free Quote

Related Blog

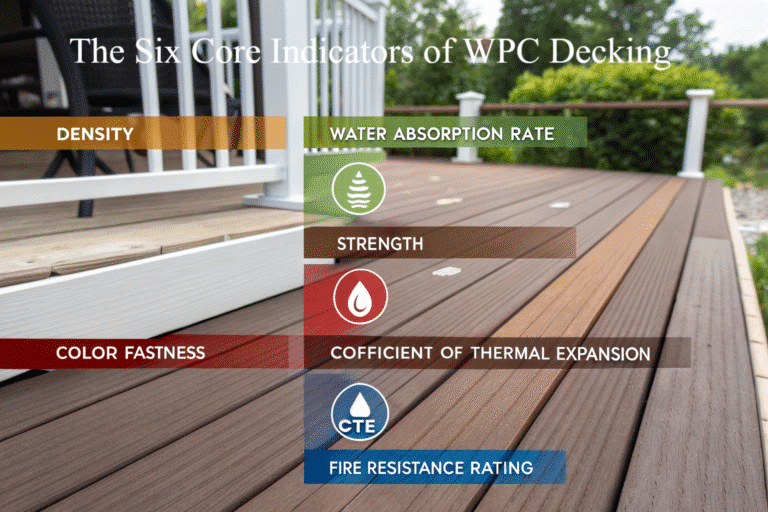

The 6 Most Important Technical Indicators of WPC Decking

When you approach the building materials market or browse e-commerce platforms, faced with hundreds or thousands of WPC decking (compos...

Should You Source WPC Fence from China?

If you are a wholesaler or project contractor, sourcing WPC fencing from China can help you cut costs significantly.

However, not all ...

Swimming Pool WPC Deck: Complete Manufacturer Guide

As a professional WPC composite decking manufacturer, we found that 90% of swimming pool projects face common issues.These include wate...

The 6 most popular WPC gate styles

As a WPC product manufacturer in China, we have collected numerous customer requirements for WPC fence gates from projects worldwide. W...

Load more posts

Loading...

2 thoughts on “How to Lay Composite Deck Joist?”

Heard some buzz ’bout 777bgame. Might be worth checking out if you’re looking for something new. Just saying 777bgame.

Xibetlogo is pretty legit, no doubt. The games keep me hooked for hours. Nice vibes all around, I say give it a shot. xibetlogo

Comments are closed.