Can You Install Composite Decking Directly on the Ground?

[seopress_breadcrumbs]

The surface of the bridge panel shall not be laid directly on the ground. The biggest problem is that direct installation may destroy the stability and safety of the overall structure of the composite deck because of the soft soil of the foundation, or the settlement of the water foundation.

Any composite bridge panel must be supported by a good base frame that complies with local building codes to ensure the surface stability of the bridge panel.

Next, we will delve into the best way to install composite decking panels on the ground.

Can Composite Decking Touch the Ground?

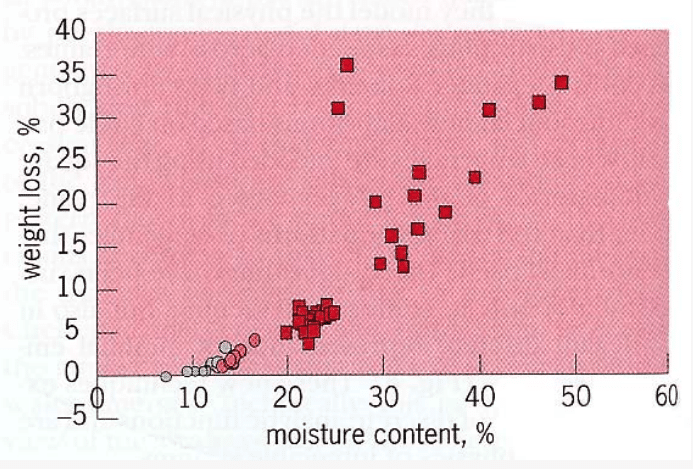

Although wood plastic composite decking (WPC) has properties such as insect and rot resistance and low water absorption, allowing it to come into direct contact with the ground, it is generally not recommended to install composite decking directly on the ground. Here’s why:

- Stability Requirements: Any decking planks require a solid underlying support structure. This support ensures that the deck remains securely in place, maintaining the stability of the surface and preventing shifting or warping over time. It also ensures the long-term reliability of the deck’s performance.

- Load-Bearing Capacity: Composite decking typically does not have the same load-bearing strength as some traditional woods, such as redwood. Direct contact with the ground may not provide adequate support, especially in cases where heavy loads are involved. Ground-level structures should use beams or joists to evenly distribute weight, ensuring the stability and safety of the decking system.

- Building Code Requirements: Many local building codes mandate a gap between the decking and the ground to ensure safety and durability. Failing to design and install the proper underlying support structure may compromise the overall safety and lifespan of the decking system and even violate local building regulations.

Benefits of Adding a Frame Between Composite Decking and the Ground

- Level Surface and Stability: Ground surfaces are often uneven, and even concrete patios may have minor imperfections. Installing composite decking directly on such surfaces can lead to an uneven deck, compromising its structural integrity and stability. Over time, these irregularities may cause sagging, warping, or structural damage, posing safety risks to users. A substructure provides a stable and level base for installation, preventing these issues.

- Effective Moisture Management: Direct contact with the ground can lead to water accumulation. Elevating the decking with a frame effectively channels rainwater and other liquids away, preventing moisture retention beneath the deck. This moisture management system reduces the risk of damage caused by dampness and significantly extends the lifespan of composite decking.

- Improved Air Circulation: By elevating the decking, the base frame allows for adequate airflow beneath the surface. This promotes faster moisture evaporation and prevents rot or mold caused by prolonged dampness, enhancing the durability and longevity of the decking.

- Height and Level Adjustment: A base frame system allows for flexible height and level adjustments, ensuring a flat and visually appealing deck surface even on uneven or irregular ground. This adaptability ensures the best possible installation outcome.

- Weight and Pressure Distribution: A substructure system evenly distributes the weight and pressure exerted on the decking, particularly under heavy loads. This prevents localized stress that could damage or deform the decking, ensuring the stability and safety of the entire structure.

- Adaptability to Various Ground Conditions: Substructure systems are highly adaptable and can be adjusted to suit different ground conditions. For instance, an adjustable system can be used on uneven surfaces, while corrosion-resistant materials are ideal for humid or damp environments. This versatility simplifies the installation process and enhances the overall stability and durability of the decking.

By incorporating a substructure system, composite decking can achieve improved performance, extended lifespan, enhanced safety, and a more polished aesthetic. It is the optimal solution for installing composite decking.

Installation Steps for Composite Decking on Concrete and Soil

Click to watch the composite deck installation video

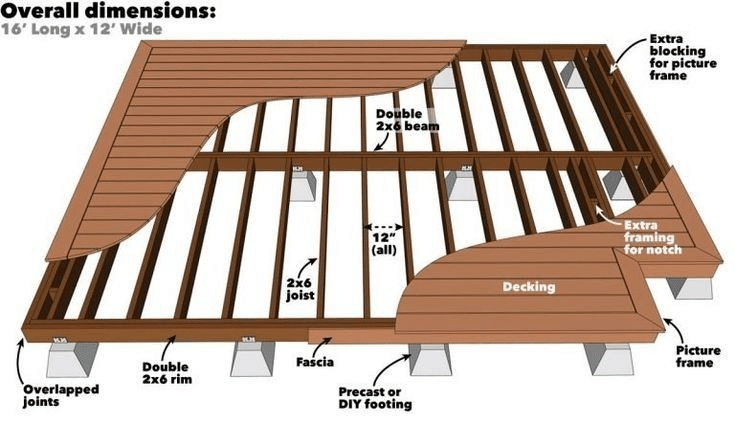

Installing Procedures | Concrete | Soil |

Ground Preparation | Clear the concrete surface of dust, debris, and gravel to ensure it is clean, level, free of loose sand, and without cracks or other issues. Check the drainage slope. | Remove weeds, stones, and other debris. Compact the soil to ensure ground stability. |

Protective Layers Installation | Install anti-corrosion pads on the concrete surface and secure them with expansion bolts. | Add weed barrier fabric or waterproof fabric to prevent plants from growing under the deck and to improve drainage. |

Support Structures Installation | Secure pads to the concrete using expansion bolts to provide a stable foundation while avoiding direct contact between the joists and concrete to improve ventilation. | For soil surfaces, install ground stakes to provide stable support for the joists. |

Joist Installation | Fix the joists onto the pads using expansion bolts or stainless steel screws at intervals of 30-40 cm | Position the joists on the ground stakes at intervals of 30-40 cm and secure them with screws, ensuring they are level. |

Composite Decking Installation | Fix the composite decking onto the joists using hidden fasteners or stainless steel screws, maintaining a gap of 5-6 mm between the boards. | Use clips, such as hidden fasteners or stainless steel screws, to secure each board and lay subsequent boards with uniform gaps (5-6 mm). |

Edge Finishing | Install edge trim at the deck edges to ensure a neat appearance and protect the deck edges. | Secure edge trim to the deck edges for aesthetics and added protection. |

Install deck on Soil:

Install deck on concrete:

In summary: Installation on concrete is relatively easy due to its stability, allowing for direct fixation. Installation on soil is more challenging, requiring ground compaction, the installation of ground stakes, and the use of weed barrier fabric.

Ecoxplank's Reliable Wood Composite Deckings

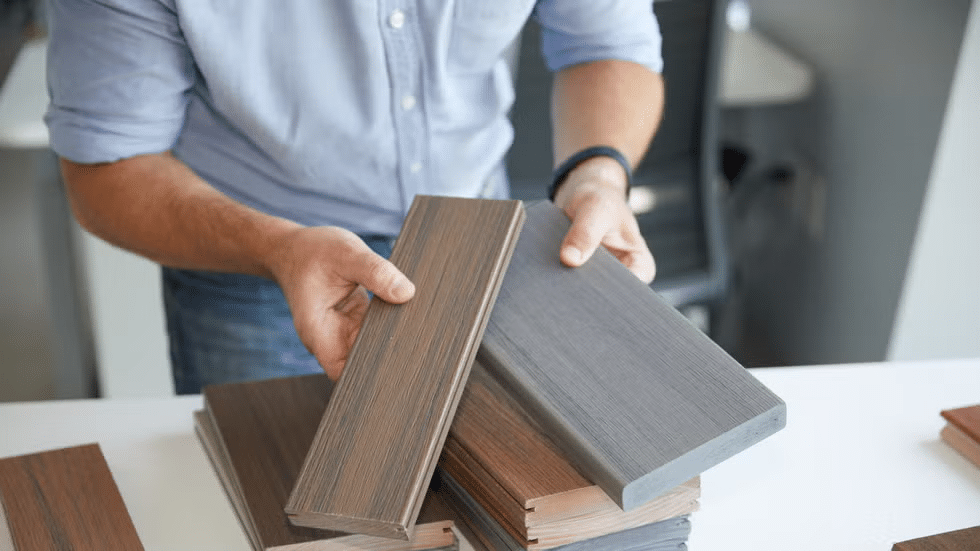

EcoxPlank’s co-extruded wood-plastic composite decking is built with a moisture-resistant layer, UV-resistant coating, and a specially formulated composite core, offering exceptional durability and eco-friendly performance.

- Moisture-Resistant Layer: This layer effectively blocks water and humidity, preventing swelling, mold, and decay, making the decking ideal for humid environments.

- UV-Resistant Coating: With UV absorbers and light stabilizers, this coating protects against fading and aging caused by direct sunlight, ensuring the decking maintains a fresh, vibrant appearance even after prolonged outdoor exposure.

- Innovative Composite Core: By optimizing the wood fiber-to-HDPE ratio and incorporating nano-enhancing materials, EcoxPlank achieves an exceptional balance of high strength, low water absorption, and superior impact resistance.

EcoxPlank also emphasizes proper installation designs, such as ventilated bases and corrosion-resistant joist supports, which minimize direct contact between the decking and the ground, further extending its lifespan.

As a leader in sustainable innovation, EcoxPlank’s composite decking boasts a remarkable 30-year durability and complies with international environmental standards, making it a premium choice for outdoor decoration worldwide.

Request a Sample to Quickly Start Your Next Project

Choose EcoxPlank’s best-quality composite decking to create a durable, elegant, and eco-friendly solution for your outdoor space! Contact us today to learn more about our products. We offer free samples and professional customization advice to help you find the perfect solution. Let EcoxPlank‘s innovative design and superior quality add value to your project!

FAQ

Will Composite Decking Rust or Rot If It Touches the Ground?

EcoxPlank composite decking is made from moisture-resistant and anti-corrosion materials, ensuring it won’t rust or rot. With superior resistance to humidity, mold, and pests, it maintains its durability even when in contact with the ground, making it an ideal choice for outdoor environments.

Does Composite Decking Still Require a Support Structure If It Touches the Ground?

Yes, while EcoxPlank composite decking can touch the ground directly, we recommend using a support structure, such as corrosion-resistant joists or ground stakes. These structures enhance ventilation, reduce moisture accumulation, and significantly extend the lifespan of the decking. They also provide better structural stability and load-bearing capacity.

What is the Ground Clearance for Composite Decking?

The recommended ground clearance for composite decking is typically 30 cm (12 inches) or more. This gap ensures proper ventilation, minimizes moisture buildup, and prevents mold and rot, extending the decking’s lifespan. In areas with heavy humidity, increasing the clearance to 45 cm (18 inches) is advisable to improve drainage and airflow further.

What is the Best Frame for Composite Decking?

The ideal frame for composite decking often includes:

Aluminum Joists: Lightweight, highly corrosion-resistant, and strong, suitable for long-term use in outdoor, humid environments.

Pressure-Treated Wood Joists:Economical and practical, these joists resist moisture and decay when treated properly.

Plastic/Composite Joists: Low-maintenance and corrosion-resistant, these are ideal for areas with high humidity.

Aluminum Joists: Lightweight, highly corrosion-resistant, and strong, suitable for long-term use in outdoor, humid environments.

Pressure-Treated Wood Joists:Economical and practical, these joists resist moisture and decay when treated properly.

Plastic/Composite Joists: Low-maintenance and corrosion-resistant, these are ideal for areas with high humidity.

Get A Free Quote

Related Blog

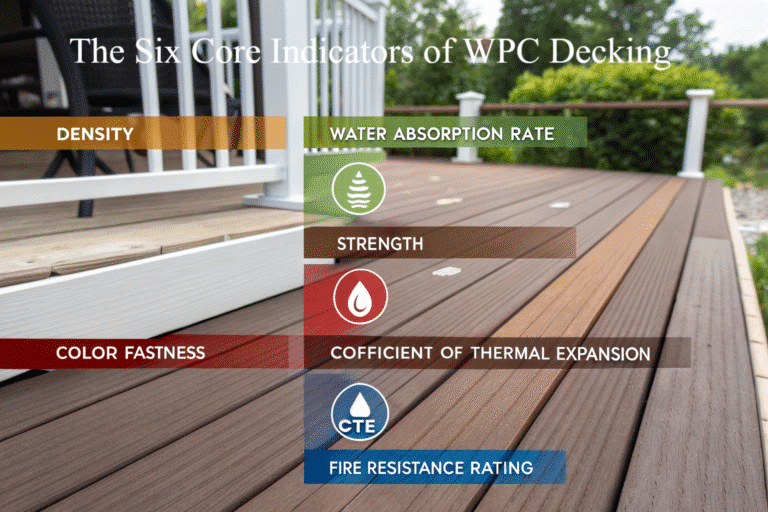

The 6 Most Important Technical Indicators of WPC Decking

When you approach the building materials market or browse e-commerce platforms, faced with hundreds or thousands of WPC decking (compos...

Should You Source WPC Fence from China?

If you are a wholesaler or project contractor, sourcing WPC fencing from China can help you cut costs significantly.

However, not all ...

Swimming Pool WPC Deck: Complete Manufacturer Guide

As a professional WPC composite decking manufacturer, we found that 90% of swimming pool projects face common issues.These include wate...

The 6 most popular WPC gate styles

As a WPC product manufacturer in China, we have collected numerous customer requirements for WPC fence gates from projects worldwide. W...

Load more posts

Loading...

4 thoughts on “Can You Install Composite Decking Directly on the Ground?”

What’s up, internet? Anyone use 9pkrgamedownload before? Curious about the selection and download speeds. Let me know! Link is here: 9pkrgamedownload

Your article helped me a lot, is there any more related content? Thanks!

PHWEN! Alright, never heard about Phwen before. It’s got a cool design, could use some update to the content though. Take a look for yourself: phwen

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Comments are closed.