Swimming Pool WPC Deck: Complete Manufacturer Guide

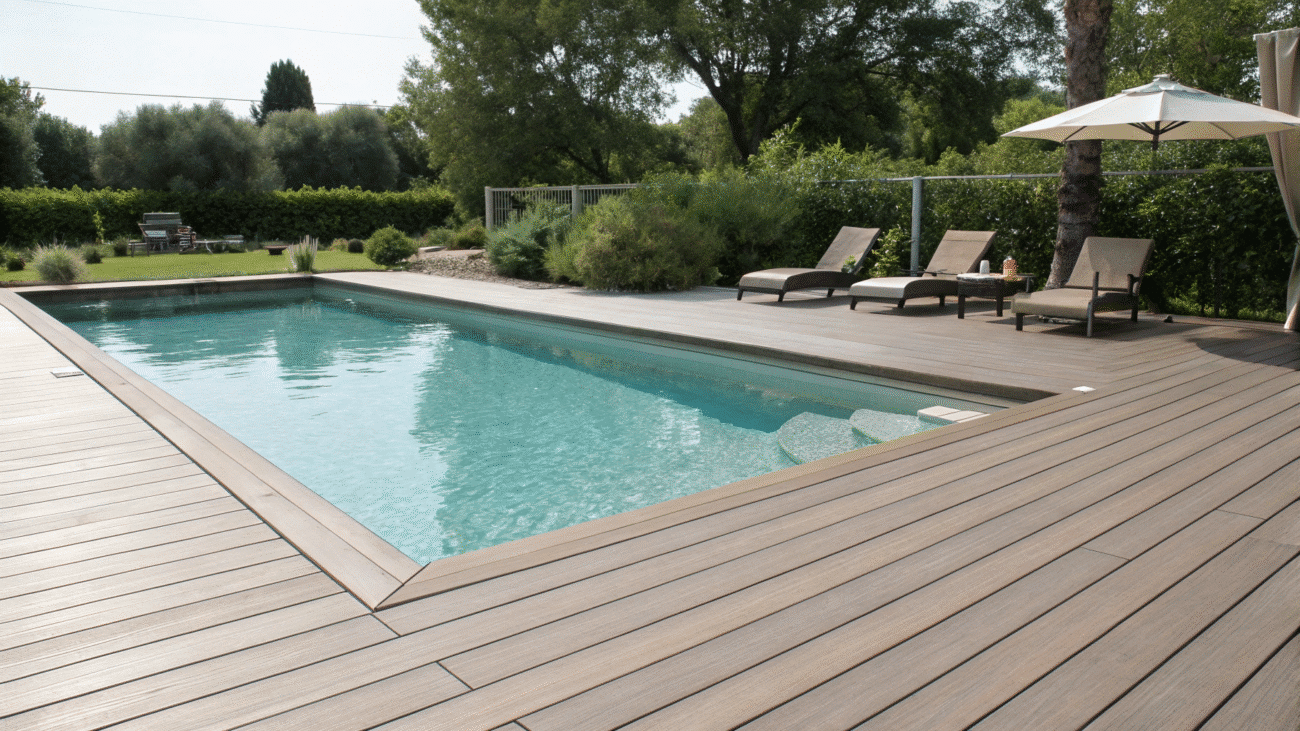

As a professional WPC composite decking manufacturer, we found that 90% of swimming pool projects face common issues.These include water penetration, slime buildup, warping, cracking, and fading problems.

This guide will help you avoid common pitfalls. You can choose the right swimming pool WPC decking material for your needs.

Last Updated: July 2025 | Estimated Reading Time: 8 minutes

This article will answer for you:

- Why is WPC deck the best choice for swimming pool areas?

- Which WPC outdoor decking type suits your pool project best?

- How can you identify truly high-quality swimming pool WPC decking material?

- How do you choose a reliable pool deck WPC manufacturer?

Why Choose WPC Deck for Swimming Pool Decking?

You can observe pool projects around you. You will notice problems with traditional materials. Real wood cracks and warps easily.

Stone surfaces become slippery and cost too much. But does WPC outdoor solve these problems? Of course!

WPC composite decking has become the top choice for 75% of high-end pool projects worldwide. This is no coincidence.

WPC decking perfectly replicates natural wood grain textures. Your pool area will look just like real wood flooring. Our 3D embossing technology creates WPC deck flooring. The touch and visual effect feel almost identical to wood grain.

Additionally, WPC composite made by Ecoxplank passes FSC certification. The wood powder content reaches 60-70% in raw materials. All materials come from recycled wood and agricultural waste. This achieves true environmental sustainability.

Professional-grade WPC decking outdoor can last 25-30 years. But this data only applies with strict joist spacing control (≤305mm) and correct installation. Even non-professional grade can last around 10 years. You might find many manufacturers claim 50-year lifespans. I tell you, that’s almost impossible.

From a manufacturing technology perspective, we now produce WPC planks with bending strength over 35MPa. This far exceeds the 20MPa standard for ordinary outdoor materials. This means even if you and your friends – 10-15 people – stand on one board for a pool party, the WPC deck flooring won’t deform.

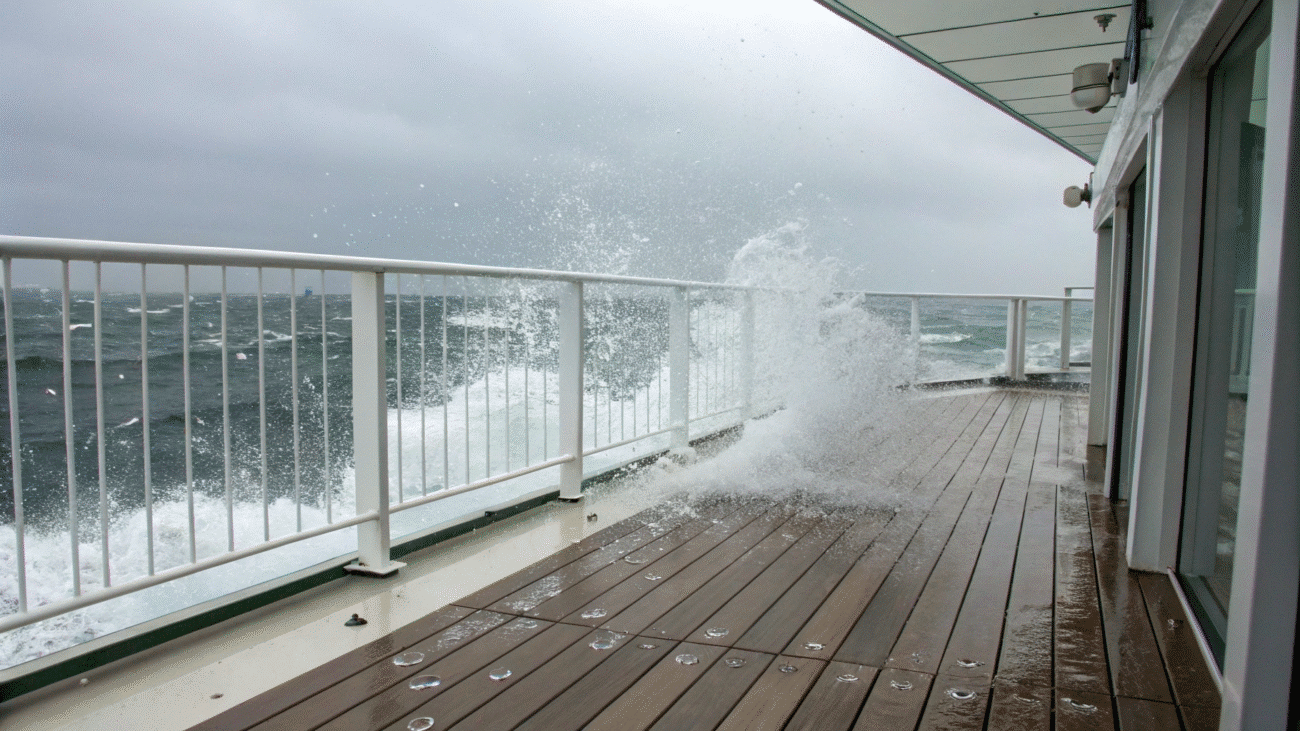

This is what you need to consider most. WPC outdoor decking contacts water for long periods.

Let’s look at test data: High-quality solid WPC controls 24-hour water absorption below 0.2%. In comparison, ordinary wood has water absorption rates of 15-20%.

You might not understand what this means. This is like coating the deck with a protective film. It can soak continuously for over 20 days in environments 1000 times more chlorinated than pool water. The color and strength won’t change at all.

Our project in Dubai proved this point. After 5 years of use, it still maintains its glossiness. You might think UV resistance isn’t important, like one of my customers did. But his previous supplier installed cheap WPC flooring around the pool. Under Dubai’s constant temperatures above 50°C, the floor started leaking slime and fading after 3 months.

So you must choose WPC decking floor with dual-layer coating technology. Its outer UV-resistant layer reaches 1.5mm thickness. This ensures no fading under intense sunlight.

You don’t need to worry about slipping. WPC floor decking surface has an anti-slip friction coefficient above 0.6. It provides sufficient grip even in wet conditions. The surface has no splinter design. It won’t scratch bare feet. This makes it especially suitable for families with children.

Moreover, Ecoxplank’s outdoor WPC passes CE certification and ASTM safety standard tests. This ensures the material releases no harmful substances. It remains eco-friendly even under high-temperature sun exposure.

If you want to use it for over 15 years without maintenance, WPC outdoor decking will satisfy you. You install it and never need to spend money again. But real wood decking needs annual maintenance. You will fall into cleaning anxiety every year. The longer the time, the more splinters, fading, and mold appear.

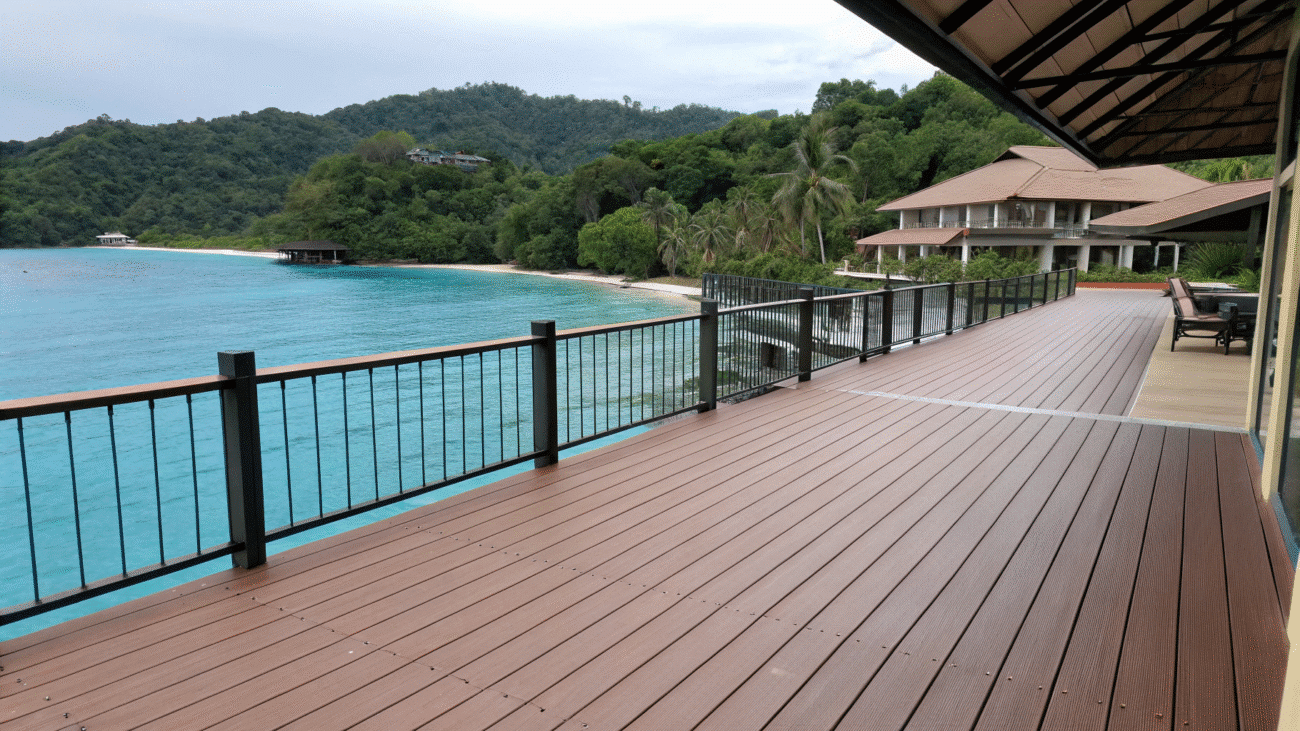

We installed our seawater-resistant WPC deck exterior at a resort in Kuala Lumpur, Malaysia in 2019. After 5 years of tropical marine climate testing, the color and structure remain like new.

What Are the Best WPC Outdoor Decking Types for Swimming Pools?

Based on our experience with 40+ pool projects worldwide, the following four types work best for swimming pool applications.

Solid WPC decking is the most pressure-resistant choice for pools. This works especially well when pools have high foot traffic. This material has better load-bearing capacity and anti-deformation performance. Bending strength can reach above 40MPa. This is 1.5 times that of hollow WPC decking. It suits commercial pools or high-frequency home pools perfectly.

This type of WPC solid board has higher density. It feels more solid when stepped on. It won’t create a hollow feeling. In pool edge areas that need to withstand diving impacts, solid WPC performs exceptionally well.

If you have commercial pools, resorts, or high-end private pools, it offers strong load-bearing capacity, solid feel, and long service life. But the cost is relatively high. The weight is heavier and requires reinforced joist support.

3D embossed WPC composite decking has rich surface texture layers. The touch feels over 95% close to natural wood. This process not only enhances appearance but also strengthens anti-slip performance. Texture depth usually ranges between 0.5-0.8mm.

Color choices are abundant. From classic teak color to modern WPC decking grey, all can blend perfectly into different pool design styles. The surface micro-textures also help hide minor scratches. This maintains long-term beauty.

If you have landscape design projects or applications that focus on aesthetic effects, this material offers real wood feel, good anti-slip properties, and high beauty. But cleaning requires attention to texture gaps. You need to avoid dirt accumulation.

Hollow WPC has the cheapest price. It achieves lightweight design through internal cavity structure. This reduces material costs while maintaining basic performance. WPC hollow board wall thickness design is optimized. Main load-bearing areas have wall thickness of 4-6mm. This ensures structural strength.

The hollow design also brings certain heat insulation effects. In hot regions, surface temperature is 3-5°C lower than solid products. This improves usage comfort.

If you have a very low budget and need large-area installation for home pools, you can choose this option. It has low cost, light weight, and good heat insulation. But load-bearing capacity is relatively low. You need to reduce joist spacing to below 250mm.

Capped technology is the highest standard in the WPC composite decking industry. The outer protective cap thickness reaches 1.5-2mm. It provides 360° comprehensive protection. This technology suits harsh pool environments particularly well. It effectively resists chloride corrosion and UV damage.

The outer protective cap uses special polymer materials. It’s not only waterproof and stain-resistant but also has self-cleaning functions. Even with long-term exposure to pool chemical environments, it maintains like-new appearance.

If you have commercial pools, seaside projects, or pools with high chemical concentrations, you should choose this material. It has the strongest protection capability, chemical corrosion resistance, and maintenance-free benefits. The downside is the highest cost.

We also created a summary table. You can choose based on your own scenario. If you’re unsure how to choose, you can also click here to contact Ecoxplank manufacturer. We will provide professional answers.

| WPC Type | Load Capacity | Cost Level | Best Suited Scenarios |

|---|---|---|---|

| Solid WPC | Highest (40MPa+) | Medium-High | High-density/high-frequency pools |

| 3D Embossed WPC | High (35MPa+) | Medium-High | Aesthetics-focused residential pools |

| Hollow WPC | Medium (25MPa+) | Low | With a limited budget family pools |

| Capped Composite | High (38MPa+) | Highest | Harsh environments/high-quality commercial projects |

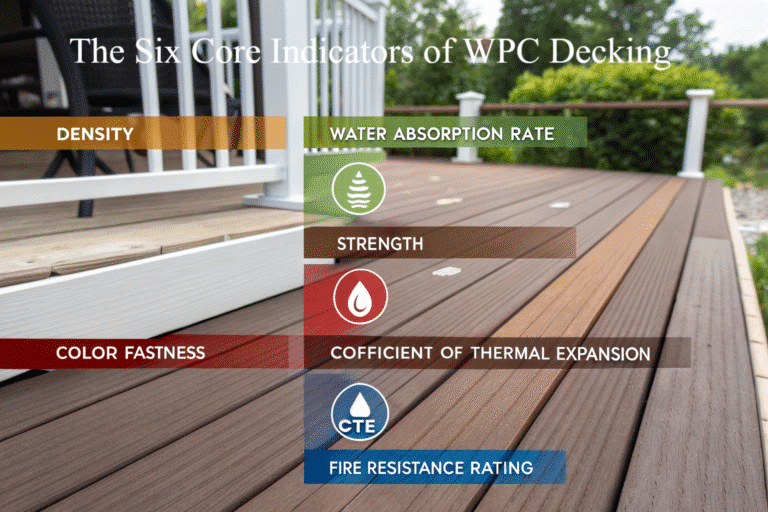

How to Choose the Right Swimming Pool WPC Deck Material?

As a professional manufacturer, we have seen too many project failures caused by wrong material choices. 90% of people only look at WPC decking price and appearance when choosing WPC decking material. This dooms them to problems.

If You Want to Choose Dual-Layer Coating?

WPC outdoor uses dual-layer coating technology. The outer UV-resistant layer thickness reaches 1.5mm. This is the key to ensuring no fading. Many manufacturers reduce the protective layer thickness to 0.8mm or even thinner to lower WPC decking price. This causes products to show obvious fading within 1-2 years.

The inspection method is simple: Ask manufacturers to provide product cross-section diagrams. They should clearly mark each layer thickness. If manufacturers cannot provide detailed layer structure explanations, you can basically judge it as a low-end product.

Many composite WPC decking products on the market claim 25-50 year lifespans. But this data can still be misleading. You cannot distinguish between true and false. If WPC deck flooring produced by Ecoxplank wants to exceed 20 years of actual service life, it must meet the following conditions:

- Joist spacing strictly controlled at ≤305mm

- Use stainless steel or hot-dip galvanized fasteners

- Reserve expansion joints according to standards

- Regular cleaning and maintenance

This means you must install according to different manufacturers’ requirements. If not, even the best WPC decking floor may have problems within 5-8 years.

Thermal Expansion and Contraction Control Standards

Professional-grade WPC floor decking must control linear expansion coefficient below 2.5×10⁻⁵/°C. This is the life-or-death line for pool applications. Exceeding this value will cause obvious expansion and contraction deformation in environments with large temperature differences. This leads to joint cracking or board warping.

So you must require suppliers to provide third-party testing reports. If they cannot provide them, we recommend choosing carefully.

Real Standards for Load-Bearing Capacity

True pool WPC bending strength must reach above 35MPa. But 80% of products on the market cannot reach this standard. Many manufacturers provide theoretical values or laboratory optimal condition data. Actual product performance may differ by 30-50%.

Inspection method: Request to see ASTM D790 bending strength test reports. Note that test conditions must be standard environment of 23°C and 50% humidity. If test results are under other conditions, reference value is limited.

Chloride Resistance Standards

Excellent WPC decking outdoor can withstand 3000ppm chlorine concentration soaking for 500 hours without changes. Many manufacturers don’t even know this test standard. This comes from our actual project experience in Indonesia.

If WPC outdoor decking cannot pass high-concentration chloride testing, it will show surface powdering, fading, or even structural damage in pool environments. This is the root cause why many cheap products have frequent problems after 1-2 years of use.

Water Absorption Standards

Seawater environment corrosivity is over 10 times that of ordinary environments. So when you choose WPC materials for seaside projects, products need to pass ASTM testing. ASTM salt spray testing simulates high-salt, high-humidity conditions of marine environments. Only products that pass testing can be used long-term in seaside pools.

If you choose unqualified products, serious corrosion problems may appear within 6 months.

Seawater Environment Standards

Excessive water absorption in WPC decking board causes material expansion and deformation. It may also cause freeze cracking in winter when freezing occurs.

Before we choose, we check the water absorption ratio in material test reports. If this indicator exceeds 0.5, we don’t recommend it for pool projects.

Professional Tip: When choosing WPC decking material, always request complete technical parameter sheets and third-party testing reports. If suppliers cannot provide these materials, or if data is vague and unclear, we recommend changing suppliers. True professional manufacturers will actively provide detailed technical documentation.

Best Decorative Color Choices for Outdoor WPC Pool Deck

In pool environments, choosing the wrong color may cause surface overheating or rapid fading problems.

Based on our project experience in different climate zones worldwide, the following color combinations perform best in swimming pool WPC deck applications.

Grey Tones

WPC decking grey is currently the mainstream choice for global pool projects. It accounts for over 60%. Grey matches perfectly with modern architectural styles.

Additionally, neutral grey has a solar light reflectance of 30-40%. This means in hot summer days, this temperature difference determines whether you can walk barefoot comfortably. Grey systems are more resistant to common pool stains (like leaf marks, water stains, etc.).

Dark Colors

Dark brown, charcoal black, and other dark WPC outdoor colors look grand in appearance. But they need special attention in pool applications. Under direct sunlight, surface temperatures can reach 50-60°C. This easily burns bare feet.

Additionally, dark products require higher UV stabilizer standards. If material quality is poor, fading will be very obvious. We don’t recommend deep grey unless it’s not exposed to sunlight.

Light Colors

Ivory white, light wood color, and other light colors are basically applied in small pool areas. Light colors have high reflectance and relatively lower surface temperatures. They suit hot regions well. Light colors also enhance the sense of open space.

Color Matching Suggestions: Consider overall landscape coordination. WPC decking grey + blue pool is a classic combination. If you pursue natural feel, choose light wood grain color with green plants. Modern minimalist style suggests choosing pure grey with geometric line design.

How to Choose the Right WPC Pool Deck Manufacturer?

From the multiple problem projects we have taken over, 90% were caused by choosing the wrong manufacturer. When choosing manufacturers, you absolutely cannot only look at WPC decking price and promotional materials. You must conduct in-depth evaluation from multiple dimensions.

Common Consequences of Wrong Manufacturer Selection

UV Additive Corner-Cutting: Because anti-UV stabilizers are expensive, costs account for 15-20% of raw material costs. Cheap product manufacturers will use low-end UV agents or reduce addition amounts. This causes serious fading in products within 6-12 months. The key is you cannot discover this after receiving goods. This will cause you great losses.

Process Technology Defects: Color retention technology requires controlling Delta E values below 2. This needs special co-extrusion processes. Only 5% of manufacturers master this technology. Manufacturers lacking this technology produce WPC composite decking with gloss levels that drop sharply within 2-3 years.

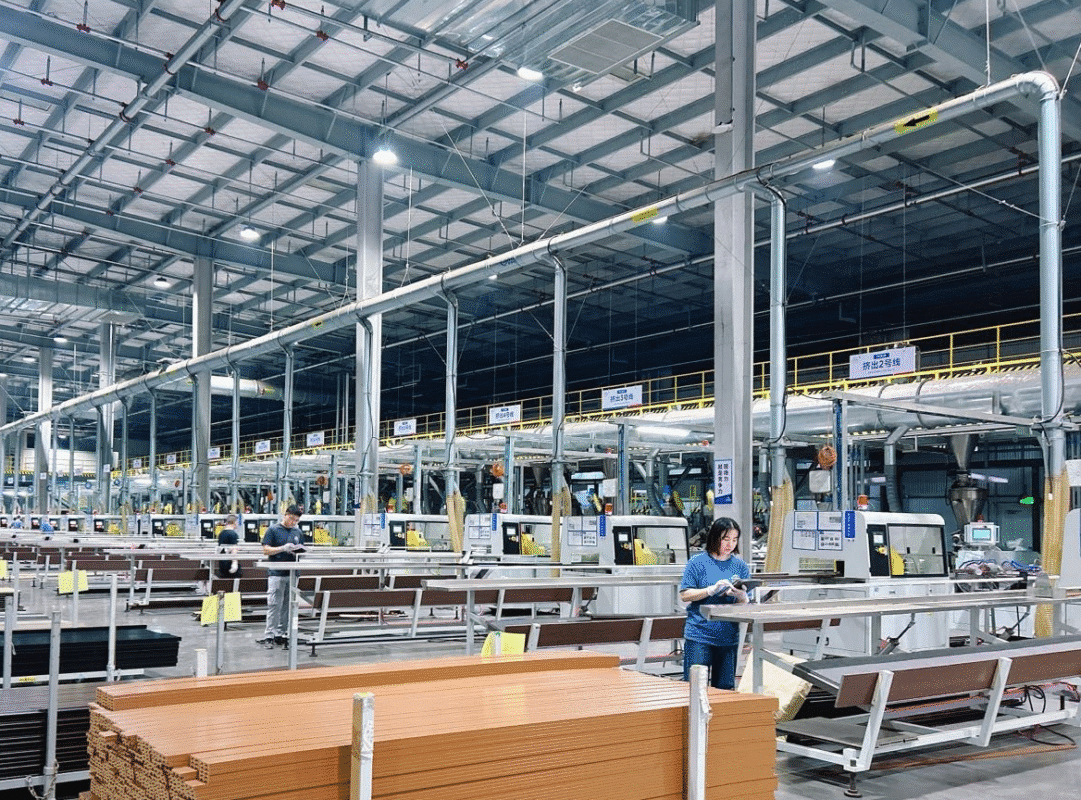

Unstable Quality Control: Some small manufacturers lack complete quality control systems. Performance differences in the same batch of products may reach over 30%. This causes inconsistent performance after installation. Ecoxplank conducts quality inspections twice before shipping. We completely match sample colors.

You Can Screen Manufacturers Through These Methods

Technical Documentation Completeness: Professional manufacturers will provide detailed installation guides, technical parameter sheets, maintenance manuals, etc. If manufacturers cannot provide these materials, or if material content is rough, this shows insufficient technical strength.

Ask Professional Questions: Ask factories about thermal expansion and contraction, joist spacing, fastener selection, and other technical issues. Professional manufacturers will immediately give detailed technical solutions.

Quality Assurance System: Look at factory production process video details. They must have standardized production lines. Understand the manufacturer’s annual capacity, production line numbers, and key equipment conditions. Professional WPC production needs expensive extrusion equipment and post-processing facilities, plus professional test reports like FSC, CE, ASTM.

Look at Global Experience Projects: For example, Dubai’s extreme high temperatures, strong UV radiation, and dust environments are ultimate tests for WPC deck exterior products. Products that can be used stably in Dubai for over 3 years will have basically no problems in other environments.

Southeast Asia: Malaysia’s high temperature, high humidity, frequent rainfall, and strong UV conditions are similar to many tropical regions.

Request Actual Photos and Videos: Ask manufacturers to provide project photos, customer contact information, usage years, and other detailed information. If manufacturers cannot provide these, this shows limited experience.

Based on our industry experience, the following types of manufacturers deserve priority consideration:

Large Comprehensive Manufacturers: Annual capacity over 10,000 tons, with complete industrial chains. They usually have strong technical strength and stable quality.

Professional WPC Manufacturers: Focus on WPC composite products for over 10 years. Although scale may not be large, they have specialized technology and strong innovation capabilities.

Internationally Certified Manufacturers: Manufacturers certified by developed countries like the US and EU. Product quality and management levels are usually higher.

Don’t choose manufacturers only based on WPC decking price. Prices that are too low often mean quality compromises. We recommend focusing on evaluating their technical strength and service capabilities. A responsible manufacturer will actively inform you of product application scope and limitation conditions.

56 thoughts on “Swimming Pool WPC Deck: Complete Manufacturer Guide”

We are a group of volunteers and starting a new scheme in our community. Your web site provided us with useful info to paintings on. You have performed an impressive process and our entire group will be thankful to you.

https://cracksports.me/basketball-streams

Just want to say your article is as astounding. The clarity in your post is simply excellent and i could assume you’re an expert on this subject. Fine with your permission let me to grab your feed to keep up to date with forthcoming post. Thanks a million and please carry on the rewarding work.

https://gullybet.tv/

I’m really inspired together with your writing talents and also with the structure in your weblog. Is that this a paid subject or did you modify it your self? Anyway keep up the excellent high quality writing, it is rare to peer a great weblog like this one today..

http://www.tlovertonet.com/

28dm65

Just wish to say your article is as amazing. The clarity in your post is just great and i could assume you are an expert on this subject. Well with your permission let me to grab your feed to keep updated with forthcoming post. Thanks a million and please keep up the enjoyable work.

https://bookthatcondo.com/

I always was interested in this topic and still am, thanks for putting up.

https://www.gorillasafariscompany.com/

ckxeh4

I truly appreciate this post. I¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

https://www.gorillasafariscompany.com/

3en62a

z3dwn1

I really pleased to find this internet site on bing, just what I was looking for : D also bookmarked.

https://appealhealthcare.com/

Absolutely indited articles, thank you for selective information. “You can do very little with faith, but you can do nothing without it.” by Samuel Butler.

https://buffsports.io/upcoming-events

I do like the manner in which you have presented this specific difficulty plus it does indeed give me personally some fodder for consideration. However, coming from what precisely I have experienced, I simply trust as the actual feed-back pack on that folks continue to be on point and in no way get started on a soap box regarding some other news of the day. Still, thank you for this superb point and even though I can not really concur with the idea in totality, I regard the point of view.

https://mlbbox.me/mlb-2024-live-streams

Very interesting topic, regards for putting up.

https://qatarstreams.me/

I’ve been absent for a while, but now I remember why I used to love this website. Thank you, I will try and check back more often. How frequently you update your web site?

https://myswissmailaddress.com

4sopxx

8okcgt

It’s a pity you don’t have a donate button! I’d definitely donate to this fantastic blog! I guess for now i’ll settle for bookmarking and adding your RSS feed to my Google account. I look forward to fresh updates and will talk about this blog with my Facebook group. Talk soon!

https://mediluxayurveda.com/

I wish to express thanks to you for bailing me out of this situation. Right after browsing throughout the world-wide-web and finding suggestions which were not helpful, I was thinking my life was done. Being alive minus the strategies to the problems you’ve resolved all through your article is a crucial case, as well as those that would have adversely affected my career if I had not encountered your website. Your good understanding and kindness in handling all the details was important. I’m not sure what I would’ve done if I had not encountered such a step like this. I’m able to at this moment look ahead to my future. Thanks a lot very much for this specialized and result oriented guide. I won’t be reluctant to propose your site to anybody who desires counselling about this subject.

https://www.clenbuterol4sale.com/clinique-dramatically-different-moisturizing-gel-review/

You have remarked very interesting details ! ps decent internet site.

https://www.gorillasafariscompany.com/

I simply could not go away your site prior to suggesting that I really loved the usual information an individual provide in your guests? Is gonna be again steadily in order to inspect new posts

https://silvioprint.it/kit/grafiche-forcellone/

Its like you read my mind! You seem to know a lot about this, like you wrote the book in it or something. I think that you could do with a few pics to drive the message home a bit, but instead of that, this is great blog. An excellent read. I will definitely be back.

https://youtu.be/ZIDvc_OuC_w

Hi! I could have sworn I’ve been to this blog before but after checking through some of the post I realized it’s new to me. Nonetheless, I’m definitely glad I found it and I’ll be bookmarking and checking back often!

https://youtu.be/JWMaV6is3ew

After examine a few of the blog posts in your web site now, and I truly like your means of blogging. I bookmarked it to my bookmark web site record and will be checking again soon. Pls take a look at my website as nicely and let me know what you think.

https://allthatjazzuk.com/

Yay google is my queen helped me to find this great web site! .

https://youtu.be/VdbP6Zf-vRs

Howdy! I know this is kinda off topic nevertheless I’d figured I’d ask. Would you be interested in trading links or maybe guest authoring a blog article or vice-versa? My site goes over a lot of the same subjects as yours and I feel we could greatly benefit from each other. If you’re interested feel free to send me an e-mail. I look forward to hearing from you! Wonderful blog by the way!

https://www.dstglobalsolutions.com/

I have been exploring for a bit for any high quality articles or weblog posts on this sort of space . Exploring in Yahoo I at last stumbled upon this site. Reading this info So i am satisfied to express that I’ve a very just right uncanny feeling I discovered exactly what I needed. I most certainly will make certain to do not overlook this site and give it a glance regularly.

https://bookthatcondo.com/

Hey there just wanted to give you a quick heads up. The text in your post seem to be running off the screen in Safari. I’m not sure if this is a formatting issue or something to do with web browser compatibility but I figured I’d post to let you know. The design look great though! Hope you get the issue fixed soon. Thanks

https://www.gorillasafariscompany.com/

You really make it seem really easy along with your presentation but I to find this matter to be actually one thing which I believe I’d by no means understand. It sort of feels too complex and very extensive for me. I am taking a look ahead in your subsequent submit, I’ll try to get the hang of it!

https://bpas.bbmpgov.in/app/62020fi7-Gullybet.shtml

You have remarked very interesting points! ps decent site.

https://cracksports.me/serie-a-streams

Very interesting info !Perfect just what I was searching for! “Peace, commerce and honest friendship with all nations entangling alliances with none.” by Thomas Jefferson.

https://mainstreams.io/soccerstreams/live

Your place is valueble for me. Thanks!…

https://www.royalminiatureschnauzer.com/available-pups/

I am really loving the theme/design of your weblog. Do you ever run into any internet browser compatibility issues? A number of my blog visitors have complained about my site not working correctly in Explorer but looks great in Safari. Do you have any tips to help fix this issue?

https://gzwdj.com/

ctfdny

Whats up! I simply would like to give an enormous thumbs up for the good info you’ve got right here on this post. I will be coming again to your weblog for more soon.

https://cracksports.me/

Thankyou for helping out, excellent information.

Great paintings! That is the kind of information that should be shared around the net. Shame on the search engines for no longer positioning this put up higher! Come on over and consult with my web site . Thanks =)

Hi there, i read your blog occasionally and i own a similar one and i was just curious if you get a lot of spam remarks? If so how do you stop it, any plugin or anything you can suggest? I get so much lately it’s driving me crazy so any support is very much appreciated.

What¦s Taking place i’m new to this, I stumbled upon this I’ve discovered It positively useful and it has helped me out loads. I hope to give a contribution & help other customers like its aided me. Great job.

Alright, straight up, g666ios works great on my iPhone. No glitches, smooth gameplay. If you’re an iOS user, give it a go. Peep it here: g666ios

I’d forever want to be update on new content on this website , saved to my bookmarks! .

What¦s Going down i am new to this, I stumbled upon this I’ve discovered It positively helpful and it has aided me out loads. I am hoping to contribute & help other customers like its aided me. Good job.

This is really interesting, You’re a very skilled blogger. I have joined your rss feed and look forward to seeking more of your fantastic post. Also, I have shared your web site in my social networks!

The following time I read a blog, I hope that it doesnt disappoint me as much as this one. I imply, I do know it was my option to read, but I truly thought youd have one thing attention-grabbing to say. All I hear is a bunch of whining about one thing that you can repair should you werent too busy on the lookout for attention.

I really enjoy looking through on this web site, it has good articles.

Thanks for one’s marvelous posting! I actually enjoyed reading it, you are a great author.I will remember to bookmark your blog and will often come back later on. I want to encourage you to continue your great work, have a nice evening!

I’m still learning from you, while I’m improving myself. I definitely liked reading everything that is posted on your website.Keep the stories coming. I enjoyed it!

Hi! Someone in my Facebook group shared this site with us so I came to check it out. I’m definitely enjoying the information. I’m bookmarking and will be tweeting this to my followers! Fantastic blog and superb design.

Been playing on jlph7 for a bit. Decent selection of games and the payouts are… okay. Worth a look if you’re scouting around. Here is the link: jlph7

Enjoyed looking at this, very good stuff, thanks. “Talk sense to a fool and he calls you foolish.” by Euripides.

Whats up very cool website!! Guy .. Excellent .. Amazing .. I’ll bookmark your blog and take the feeds also?KI am happy to seek out so many useful info right here within the put up, we want develop extra strategies in this regard, thank you for sharing. . . . . .

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

It’s the best time to make a few plans for the long run and it’s time to be happy. I’ve read this publish and if I may I desire to counsel you some interesting things or suggestions. Maybe you can write subsequent articles regarding this article. I want to learn even more things about it!

Very interesting subject , thanks for posting.

I conceive this web site contains some really superb information for everyone. “Dealing with network executives is like being nibbled to death by ducks.” by Eric Sevareid.

Its like you read my mind! You seem to know so much about this, like you wrote the book in it or something. I think that you could do with a few pics to drive the message home a little bit, but instead of that, this is excellent blog. An excellent read. I will certainly be back.

Comments are closed.