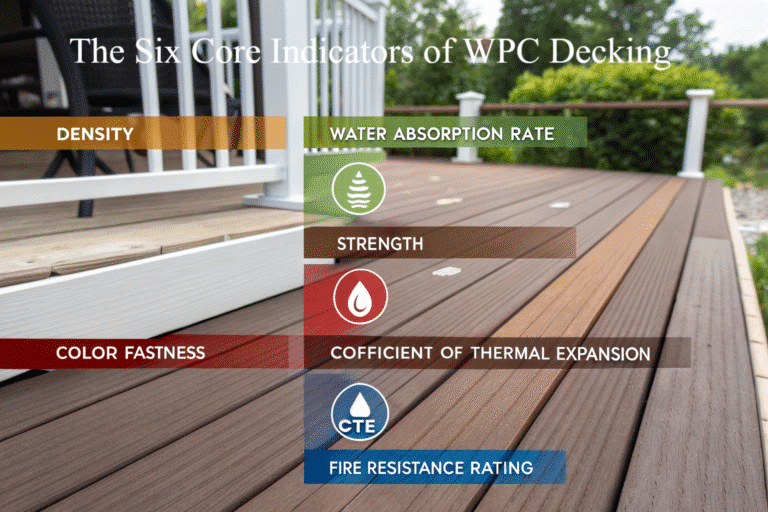

The 6 Most Important Technical Indicators of WPC Decking

When you approach the building materials market or browse e-commerce platforms, faced with hundreds or thousands of WPC decking (composite decking) products, do you feel dazzled or confused? Some products claim to be "sturdy and wear-resistant", others focus on "waterproof and fireproof", and some emphasize "environmental protection and pollution-free"—which one is more suitable for your project? WPC decking prices range from a few dollars to dozens of dollars: will cheap products be of poor quality? Will expensive ones mean wasting money?

The root of this confusion is often a lack of understanding of WPC decking’s core technical indicators. Once you grasp the meaning of these professional terms, you can avoid the risk of overpaying for inferior products. This article will break down the 6 key technical indicators of WPC decking (applicable to WPC wall panels, WPC fence panels, etc.) in plain language. Master these, and you’ll quickly identify quality among countless products, becoming a WPC selection expert.

Density: WPC Decking Strength Guarantee

Density refers to the weight of WPC decking boards per unit volume, usually measured in g/cm³. In some countries (e.g., China), density is also expressed as weight per meter length (Weight per Meter) in kg/m.

Reasonable Density Range

The ideal density range for WPC decking is 0.9–1.4 g/cm³. Higher density isn’t always better—choose based on your scenario:

- Home terraces/balconies: Use hollow WPC decking with lower density (0.9–1.2 g/cm³).

- High-traffic commercial areas: Opt for solid WPC decking with medium density (1.2–1.3 g/cm³).

- Heavy-traffic public areas (e.g., docks): Select ultra-high-density solid WPC decking (above 1.3 g/cm³).

How Density Affects Performance

| Performance | Details |

|---|---|

| Strength | High density boosts load-bearing capacity but increases brittleness, making boards prone to fracture in extreme cold. |

| Durability | Higher density enhances wear and impact resistance ( ISO 179-1), ideal for outdoor use. |

| Cost | For the same product type, higher density means higher costs; lower density is more economical. |

| Weight | Higher density increases weight; lower density makes transportation easier. |

| Water Absorption | Tighter packing in high-density products reduces water absorption (EN 317) and improves weather resistance. |

| Thermal & Sound Insulation | Higher density typically improves thermal and sound insulation. |

| Maintenance Cost | High-density products reduce long-term maintenance expenses. |

Water Absorption Rate: WPC Decking Waterproof Performance Indicator

Water absorption rate is the percentage of water mass absorbed by WPC decking boards in extremely wet or high-humidity environments relative to their dry weight (ASTM D7031-13). It reflects the material’s resistance to moisture and stability in humid conditions.

WPC Decking With Different Water Absorption Rates

Reasonable Absorption Range

International standards measure absorption after 24-hour and 7-day immersion:

- 24-hour immersion: 0.2%–2%

- 7-day immersion: 1%–5%

Choose based on environment:

- High-humidity areas (docks, pools): <1% (24-hour).

- General outdoor use: 1%–1.5% (24-hour).

- Indoor use: Relax to ≤2% (24-hour).

How Water Absorption Affects Performance

| Performance | Details |

|---|---|

| Dimensional Stability | High absorption causes expansion when wet and shrinkage when dry, leading to warping, deformation, and reduced installation accuracy/lifespan. |

| Strength | Excessive absorption weakens board strength, compromising load-bearing capacity. |

| Durability | High absorption raises risks of mildew, rot, and microbial growth—critical in outdoor high-humidity environments. |

| Appearance | Water absorption can cause fading, cracking, or blistering, harming aesthetics. |

| Service Life | Low-absorption products last longer in outdoor exposure to rain/snow. |

| Cost | Low absorption often requires costlier processes (e.g., co-extrusion) or high plastic content—balance performance and budget. |

Strength: WPC Decking’s Resistance to External Forces

Strength measures a WPC deck’s ability to resist damage from external forces, directly determining its suitability for load-bearing and impact scenarios. Key metrics include bending strength and impact strength.

Reasonable Strength Ranges

| Strength Type | Definition | Reasonable Range by Scenario |

|---|---|---|

| Bending Strength | Resistance to fracture under load (e.g., from people or furniture). | – Residential: >30 MPa – Commercial: >50 MPa – Public facilities: >60 MPa |

| Impact Strength | Resistance to sudden impacts (e.g., falling heavy objects). | – Residential: >10 kJ/m² – Commercial: >15 kJ/m² – Public facilities: >18 kJ/m² |

How Strength Affects Performance

- Higher strength means better load-bearing and impact resistance; low strength increases risk of bending or fracture.

- Insufficient strength leads to fatigue damage under repeated stress (e.g., foot traffic, wind), shortening lifespan.

- Match strength to your scenario to avoid "overdesign" (unnecessary cost) or "underdesign" (frequent replacements).

Color Fastness: Preventing WPC Decking Fading

Color fastness is a WPC deck’s ability to retain color stability under external factors like light, friction, humidity, and temperature. It’s critical for outdoor aesthetics, rated 1–5 using a "grayscale card" (5 = no color change; 1 = severe fading).

Recommended Color Fastness by Scenario

- Outdoor decking: Exposed to UV, heat, humidity, and rain—require ≥4 (prioritize high-fastness co-extruded WPC).

- Indoor/slight fading tolerance: ≥3 is sufficient.

How Color Fastness Affects Performance

| Performance | Details |

|---|---|

| Aesthetics | Poor fastness causes rapid fading, discoloration, or uneven color, making decks look aged and harming user experience. |

| Durability | Low fastness often accompanies surface aging (cracking, chalking), further reducing structural strength. |

| Maintenance Cost | Poor fastness requires frequent refinishing (repainting, sanding), increasing upkeep expenses. |

| Environmental Adaptability | High fastness resists harsh conditions in strong UV or coastal humid environments. |

Coefficient of Thermal Expansion: Explaining WPC Decking’s Thermal Expansion/Contraction

The Coefficient of Thermal Expansion (CTE) measures how much WPC decking changes dimension with temperature variations, critical for installation design, stability, and long-term performance. It’s expressed in 10⁻⁶/°C or µm/m·°C.

Reasonable CTE Range

CTE varies by formula, process, and design—industry range: 25–60 µm/m·°C.

Choose based on environment:

- Courtyards/terraces (large temperature swings): 30–50 µm/m·°C.

- Indoor/semi-indoor (stable temps): 50–60 µm/m·°C is acceptable.

- Seamless splicing/extreme environments (deserts, docks): 25–40 µm/m·°C (use co-extruded WPC).

How CTE Affects Performance

| Performance | Details |

|---|---|

| Installation Design | High CTE requires larger expansion gaps, increasing installation complexity and cost. Low CTE allows tighter splicing, reducing complexity and boosting aesthetics. |

| Dimensional Stability | In regions with large temperature differences (e.g., North America, Northern Europe), insufficient expansion gaps cause warping or cracking. Years of expansion/contraction wear edges or loosen fasteners. |

| Strength Attenuation | Excessive CTE leads to microcracks in fibers/plastics after repeated expansion/contraction, reducing flexural and impact strength. |

| Durability | Overexpansion concentrates stress, accelerating material fatigue or cracking and shortening lifespan. |

| Environmental Adaptability | Low CTE better resists temperature-induced deformation in extreme climates (deserts, cold regions). |

| Maintenance Cost | High CTE increases maintenance frequency (adjusting joints, replacing warped boards), raising costs. |

Fire Resistance Rating: WPC Decking Safety Guarantee

Fire resistance rating measures a WPC deck’s ability to resist combustion, flame spread, and smoke production in fires. It impacts safety, applicability, and compliance with building codes.

International Rating Standards

Different regions use standards like EN 13501-1 (Europe), ASTM E84 (U.S.), and GB 8624-2012 (China). This article references ASTM E84, which classifies ratings A (best) → B → C (worst).

Recommended Fire Ratings by Scenario

- Public places (malls, hotel terraces): Require B or higher for low flame spread and smoke.

- Residential outdoor decks: C or higher suffices (cost-effective, meets basic safety).

- Indoor use: Lower ratings acceptable but must comply with local codes.

- High-risk areas (near fire sources, critical buildings): Require A.

How Fire Rating Affects Performance

| Performance | Details |

|---|---|

| Safety | High ratings reduce fire risk, suitable for public and residential use. |

| Regulatory Compliance | Many regions (EU, U.S.) mandate specific fire ratings for outdoor flooring. |

| Durability | High-rated WPC decks have low heat release and smoke production, reducing fire damage. |

| Aesthetics | Flame retardants may affect color stability—balance fire rating and color fastness. |

| Cost | High ratings require more flame retardants or co-extrusion, increasing production costs. |

Conclusion

By understanding these 6 technical indicators, you’ll confidently select WPC decking that balances performance, durability, and cost for your specific project needs.

Resourse

WPC wall panels———————ECOXPLANK

WPC fence panels——————–ECOXPLANK

ISO 179-1——————————CDN

EN 317———————————-iTeh Standards

ASTM D7031-13———————-ASTM International