Inspection Details

Key Part of Quality Management and performance management

The Ecoxplank WPC (wood plastic composite) product line uses a proven QC system to test and inspect every aspect of our outdoor composite WPC materials.From chemical element analysis to hazardous gas emissions and SRI value performance, our QC systems ensure that all Ecoxplank WPC product lines meet multiple stringent standards.

Raw Material Inspection

WPC wood powder inspection

Ecoxplank's high grade wood powder coating technology and polymer modification technology can enhance the compatibility of the PE substrate with the wood powder.

Chemical gas detection

The mobile spectrometer enables our technical department to test the chemical composition and moisture content of WPC raw materials to ensure that wpc raw materials comply with our procurement specifications.

High quality PE raw material particles

High-quality PE particles, each particle does not have any impurities, defects, uniform texture, uniform particle density and fine.

WPC PE inspection

Store Pe and wood flour raw materials independently to avoid increasing material moisture content.

Strict hierarchical regional division and management.

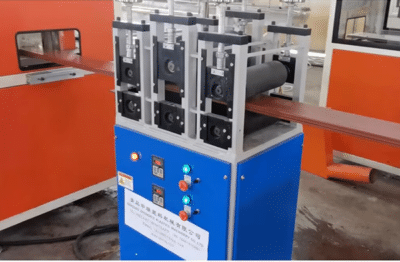

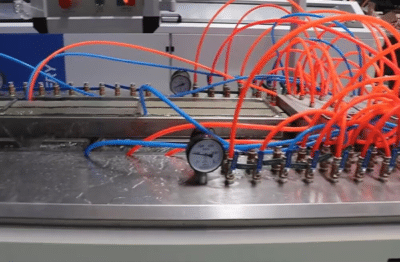

Production process inspection

WPC dosing and mixing monitoring

Ecoxplank is programmed with proportioning. Ensure that the ratio of additives and raw materials is accurate, and mixed evenly to ensure that there is no color difference or insufficient strength.

Granulation and drying test

Automatic detection of temperature and pressure during the granulation process. Avoid uneven heat or overheating, resulting in bubbles, to ensure that the moisture content of wood flour meets the drying standard.

WPC extrusion testing

Monitor the temperature and pressure of the extruded billet in real time to ensure that each WPC product will not have defects, uneven, and other problems during the billet process. To meet the standards of product shape and size.

Cooling balance test

Test the expansion and contraction performance of WPC products in forming, water condensation cooling, to check their temperature resistance and deformation.

Physical molding temperature control

It is mainly controlled under high pressure, and the consistency of temperature and humidity and pressure equivalent of the type wall under the design kg/m index. In this way, the strength and physical properties of WPC products are better.

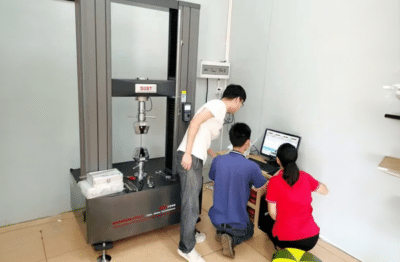

WPC Finished Product Inspection

WPC high temperature boiling test

Continuous boiling over 40 days high temperature boiling test. Temperature 95 degrees, soaked and boiled. Make sure there is no distortion or cracking. Test for weather resistance in extreme environments.

WPC bending pressure test

It is used to test the mechanical properties of WPC products such as bending strength, compressive strength and tensile strength

Detection of hazardous substances

Test formaldehyde release, heavy metal content (soluble lead, soluble cadmium, soluble chromium, soluble mercury) to ensure that WPC products comply with GBT35612-2017 standards.

Physical property test

Ecoxplank requires that the wall thickness of WPC products, whether hollow or round hole structure, must be greater than 4.5mm, in accordance with the national standard GB/T24508-2020, the minimum concentrated load ≥3400N, and the static bending strength ≥26Mpa

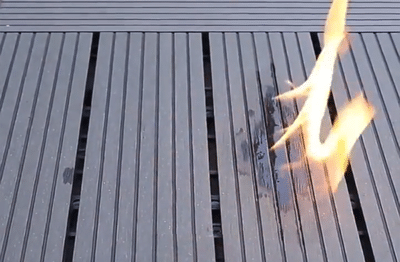

WPC fire resistance test

Test combustion temperature, combustion characteristics and gas release to test and evaluate the flame retardancy and safety of WPC finished products.

Meeting Your Quality Requirements by All Means

Ecoxplank has passed national standard tests, and professional tests conducted in conjunction with third-party institutions, including: LY/T 1613-2004, GB/T 24508-2009, GB/T 24137-2009, BS DD CEN/TS 15534-2:2007, ASTM D7032-14, ASTM D7031-11, ASTM D6109-13, ASTM D4495-12, ASTM D2394-05(2011), ASTM D696-08.

Through professional testing, we ensure that all WPC (wood plastic composite) comply with construction, outdoor and indoor industry standards. The test content covers: bending strength, bending modulus, drop hammer impact, friction coefficient, wear performance, linear expansion coefficient, tensile strength, compressive strength, shear strength, water content, water absorption thickness expansion rate, heating size change rate, nail holding force, weather resistance, hardness, frost resistance, creep.

The results provided by these agencies show the extent to which our wpc range meets your business or project requirements.

The lowest cost strategy is to choose a reliable Ecoxnplank WPC product

Ecoxplank has experienced specialists specializing in the manufacture of WPC composites and provides technical support and one-stop solutions for the global market.