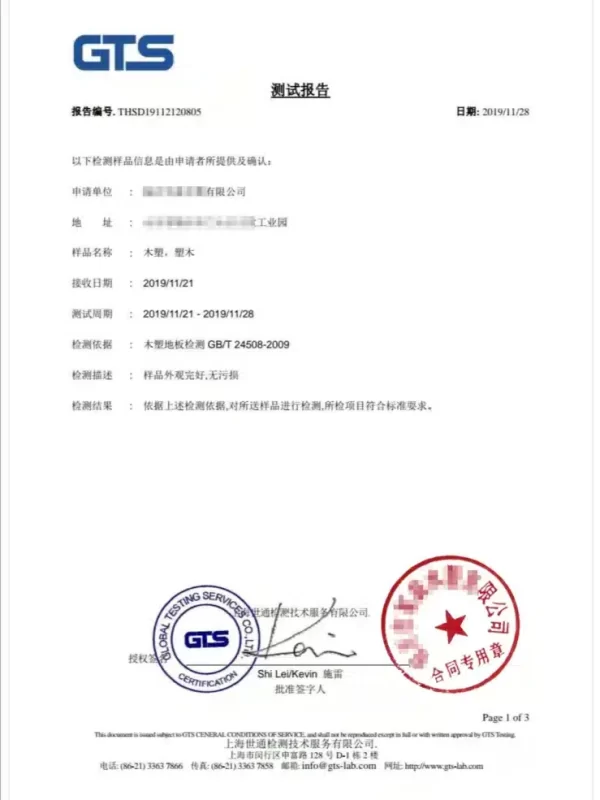

Authoritatively Certified

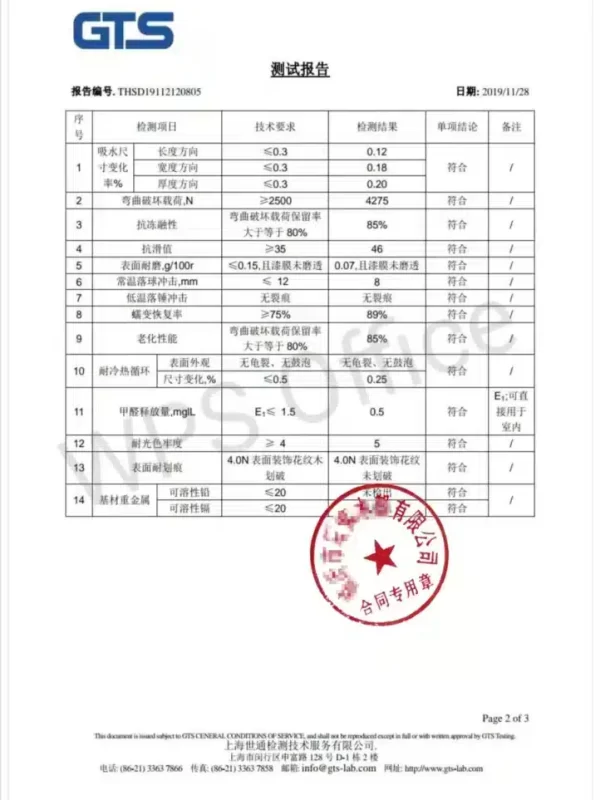

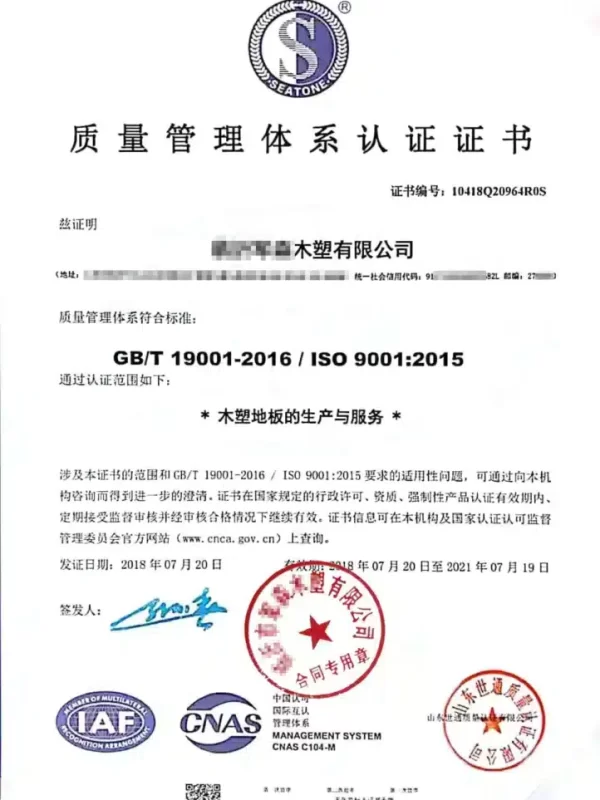

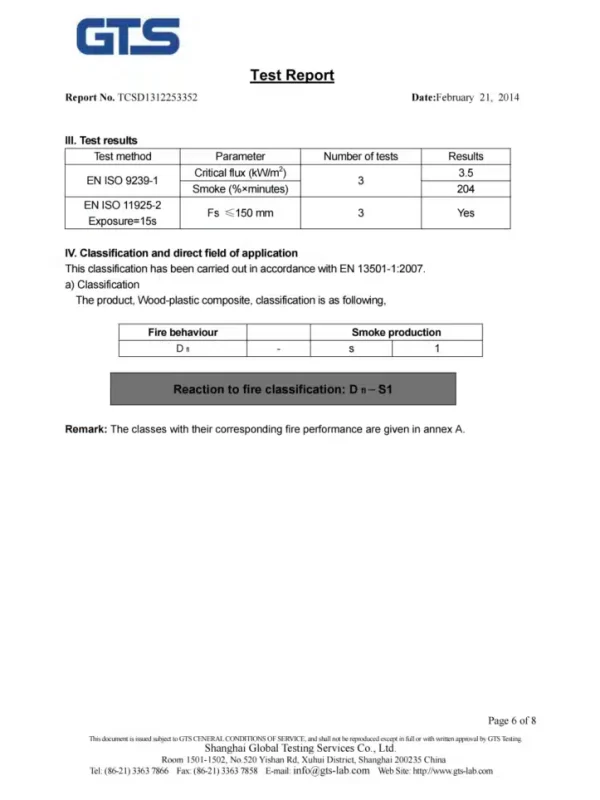

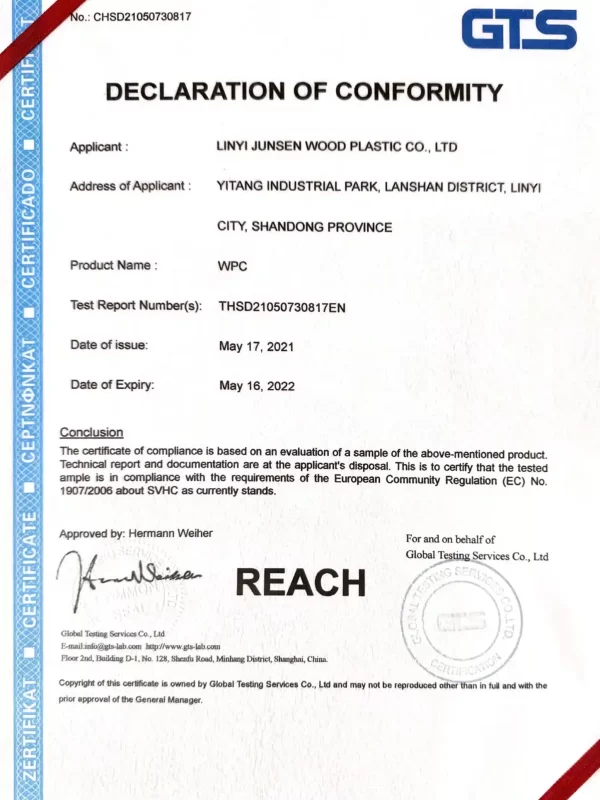

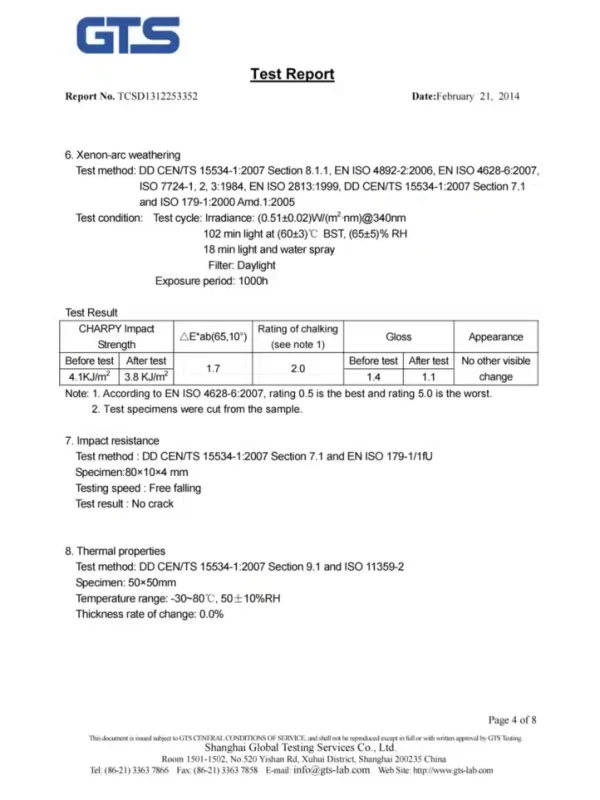

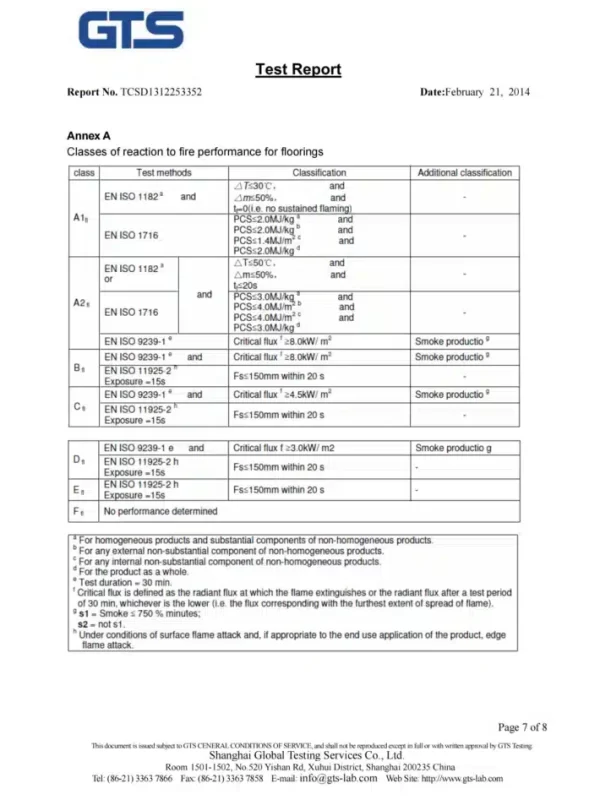

As our factory complies with ISO quality management requirements, EcoxPlank’s products are made following SGS,CE, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.