ASA Co-Extrusion Manufacturer & Supplier China

Premium ASA Co-extrusion outdoor series products Manufacturer and Supplier

Ecoxplank ASA co-extrusion products are made of ASA polymer materials and PVC co-extrusion products. ASA is a material

similar to acrylic and is internationally recognized as two polymer materials that are not easy to fade. ASA material contains about 50% acrylic components, which is more beneficial to anti-aging

and anti-fading when used outdoors in terms of material properties.

We adhere to scientific proportions, use imported high-end ASA high-grade materials, control every link well,

and produce the best quality, so that customers can feel comfortable when they see it and feel at ease when they

use it, and they can feel our intentions.

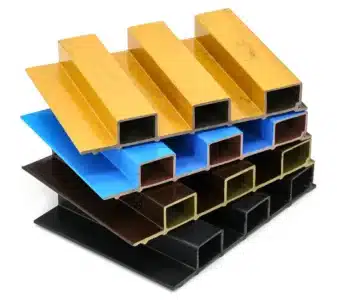

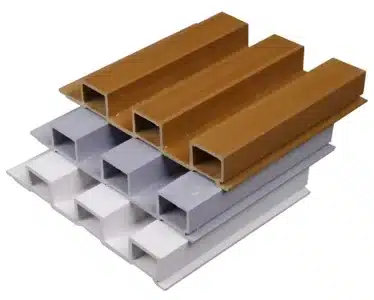

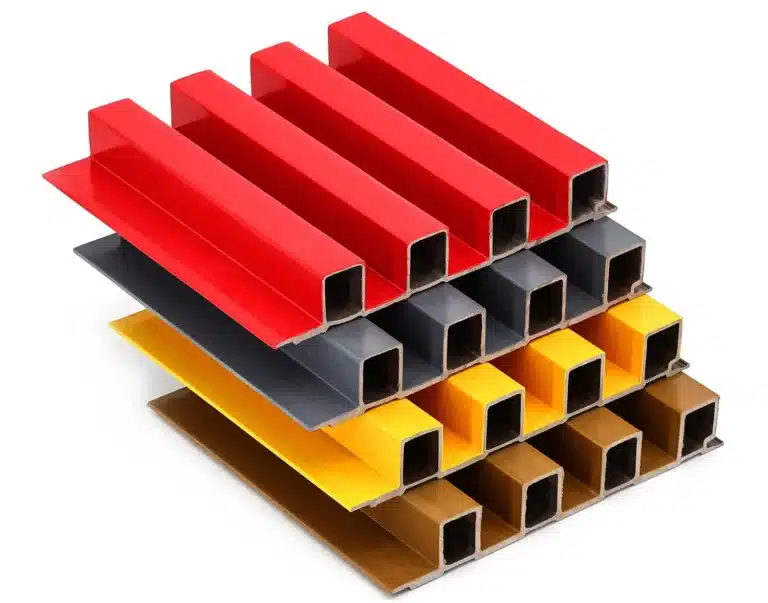

Wholesale Custom ASA Co-extrusion Products

Our ASA Co-extrusion is available in more than 20 colors, regardless product size can be customized.

ASA Co-extrusion Floor

ASA Co-extrusion Grille

ASA Co-extrusion Fence

ASA Co-extrusion Wave Board

ASA Co-extrusion Outdoor Floor

140*22 Outdoor floor

Product Size: 140*22

Length: 4 meters

ASA Co-extrusion Outdoor Grille

219*26 Outdoor grille

Product Size: 140*22

Length: 4 meters

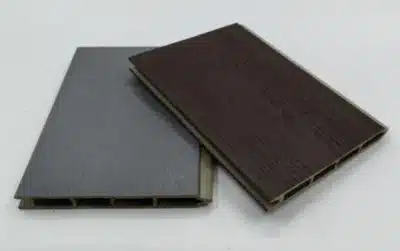

ASA Co-extrusion Outdoor Fence

150*15 Outdoor Fence

Material: ASA WPC Co-extrusion

Product Size: 150*15

Length: 3 meters

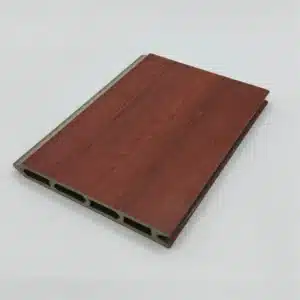

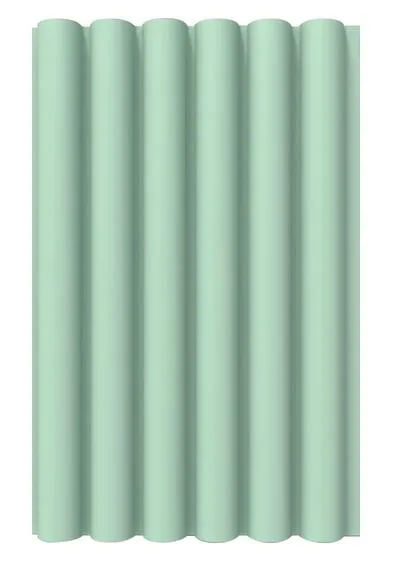

ASA Co-extrusion Wall Panels

100*17 mm Outdoor Wall Panel

Material: ASA WPC Co-extrusion

Product Size: 100*17 mm

Length: 3 meters

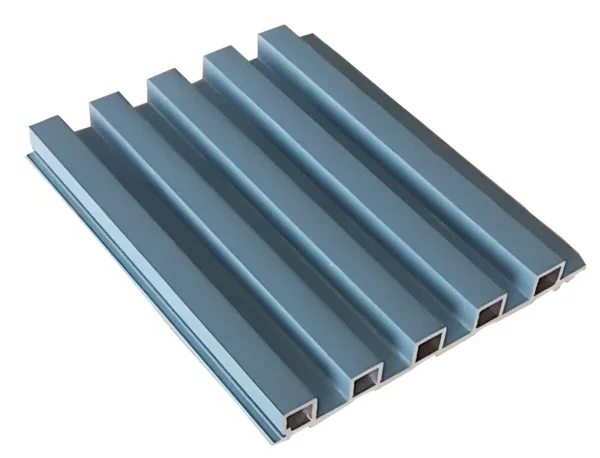

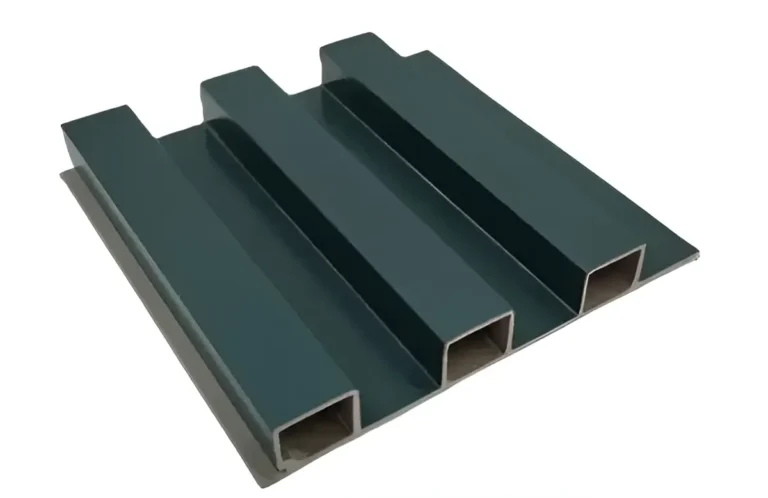

ASA Co-extrusion Outdoor Grille

195*28 mm Outdoor Grille

Material: ASA WPC Co-extrusion

Product Size: 195*28 mm

Length: 3 meters

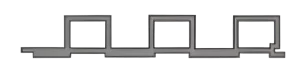

Cross Section Mold Drawing

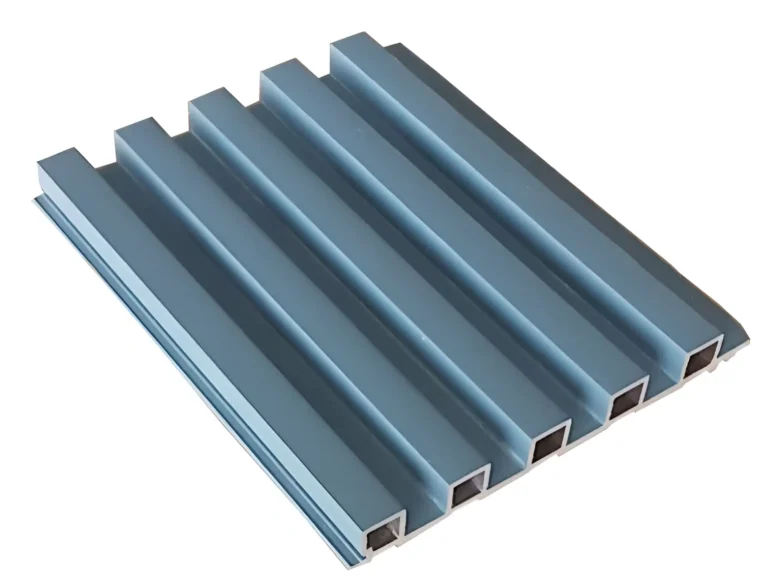

ASA Co-extrusion Outdoor Grille

150*16 mm Outdoor Grille

Material: ASA WPC Co-extrusion

Product Size: 150*16 mm

Length: 3 meters

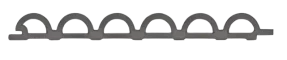

Cross Section Mold Drawing

ASA Co-extrusion Outdoor Wave Board

100*8 mm Outdoor Wave Board

Material: ASA WPC Co-extrusion

Product Size: 100*8 mm

Length: 3 meters

Available Colors

Monochrome series

Dream Blue

Chinese Red

Orange

Green Orange

Black

Emerald Green

Pink

White

White

Yellow

Coffee

Wood Grain series

Golden Maple

Straight grain teak

Metalic gray

Mahogany

Old Wood

Rosewood

Sandalwood

Yayou

Log

Black walnut

What is ASA co-extrusion?

ASA co-extrusion refers to a manufacturing process where Acrylonitrile Styrene Acrylate (ASA) is used as a top layer (or cap layer) over a base material, typically through a process known as co-extrusion. This process is commonly used in the production of building materials like decking, siding, and other outdoor products that require enhanced weather resistance.

There are two differences between the third generation ASA and the second generation PE wood plastic:

1. First of all, the core material of co-extruded ASA products is PVC, which is micro-foamed. The round shape has better load-bearing capacity and plasticity, which results in the coexistence of rigidity and flexibility in the product. It is far more rigid than PE wood plastic, but lacks product. The flexible one is much better.

2. Our product ASA is recognized as the best outdoor anti-fading material in the world. The price of our product is higher than the price of the first-generation ordinary wood-plastic and lower than the price of the second-generation co-extruded PE wood-plastic, which shows that the product is in the market. It is more cost-effective and practical for outdoor use.

3. The second generation of PE is PE+calcium powder, which is non-foaming. It is like the products being squeezed together, relatively brittle, and only focuses on rigidity, but no elasticity. The amount of calcium powder added is about 250%, so the bending strength is poor. Because the amount of calcium powder added is large, the surface of the product will easily calcify after being used outdoors for a long time (the powder will fall off when used outdoors, and the product will decompose)

What is ASA?

Introduction to ASA: ASA is currently recognized as one of the polymer materials with the best anti-fading effect for outdoor use in the world. ASA is copolymerized from styrene, acrylonitrile and acrylic rubber. Technically speaking, ASA not only maintains the main characteristics of ABS, but also combines the weather-resistant advantages of acrylic, allowing the product’s application to be extended to outdoor uses. Weather resistance, long-term use, and color stability make ASA co-extruded products a wider range of outdoor products with higher value. It is an engineering plastic that is widely used in the aerospace and automotive fields. We have applied this product to building materials.

What is Co-Extrusion?

Co-extrusion is: extruded from different extrusion channels through equipment plasticization into the same mold and then water-cooled to form. It is not a directly attached film, but a co-extruded film. It is weather-resistant, waterproof, anti-fading, and anti-fading. termite. The co-extrusion process is used in the military industry, aerospace, automobiles, etc.

What is the density of Co-Extruded ASA?

The density of the core material is 0.8kg/m3. The surface layer of this product is not foamed and is pure ASA. The price is very expensive. It is currently the best polymer material in the world for outdoor use, anti-fading and anti-aging.

What are the differences between co-extruded ASA outdoor products and indoor products:

The density of grids used indoors is only about 0.6kg/m3. However, through the combination of plastic modification and wood-plastic products in the material and density of our products, we have achieved a brand-new product that can be used outdoors.

Traditional ecological wood is made of PVC as the main material, with a foaming density of about 0.6. If used outdoors, its weather resistance, expansion coefficient, deformation rate, and fading rate are very poor, so it cannot be used outdoors. The density of the base material of our product is about 0.85, which greatly improves the weather resistance of the product for outdoor use, greatly reduces the deformation rate of the product, and has made a qualitative leap in the anti-aging and anti-fading aspects of the product, ensuring that the product The fading rate within 15 years will not exceed 5%.

Product application scope:

The company’s products are divided into two series: single color series and wood grain series products.

Application scope of monochromatic products: advertising, door signs, shop signs, wood grain series products: villa facades, building exterior walls, public place exterior walls. Orders of this type are generally engineering projects with large volumes. For some, the unit profit can be reduced appropriately.

Can the product be used indoors:

Of course, the surface of our company’s products is not covered with PVC film, but is a product that is co-extruded with a mold during production. The skin layer and the bottom layer are completely integrated, so the product does not contain harmful glue, formaldehyde, benzene and other harmful substances. It does not contain substances and does not contain the ink smell of PVC film or printing process. It will not peel off, the color is brighter and more environmentally friendly.

Is the co-extruded ASA attached on the surface through glue?

No, it is a product co-extruded from a mold. The skin layer and core layer of the product are completely integrated into a whole, so the product does not contain glue. Traditional products with sunscreen PVC films are prone to fading and blistering after being used outdoors for a long time. Such problems will not occur with our product.

How many years can our product be used outdoors?

Our company’s own testing shows that the fading rate within 15 years will not exceed 5%.

How much floor accessories are needed per square meter?

The keel is 3 meters per square meter and the buckles are 20 per square meter.

What is the difference between plastic buckles and stainless steel buckles?

After the plastic buckle is installed, the gap is 5MM, and the stainless steel buckle is 2MM.

The ground has been waterproofed. How to install the floor?

If the ground is waterproof, then the keel should not be fixed with expansion screws, but directly fixed with nail-free glue. After the overall installation, the floor will not move.

How to install wall panels and grilles?

You can drill keels on the wall and then fix them to the keels with gun nails, or you can use foam glue to fix them directly to the wall.

Is ASA co-extrusion Right for You?

Understanding ASA Co-Extrusion

ASA co-extrusion combines a durable Acrylonitrile Styrene Acrylate (ASA) top layer with a robust base material like wood-plastic composite (WPC) or PVC. This innovative process creates a product that is exceptionally resistant to weathering, UV rays, and environmental wear, making it a top choice for various outdoor applications.

Benefits of ASA Co-Extrusion

- Weather Resistance: ASA’s UV-resistant properties make sure that your outdoor products won’t fade, even after years of sun exposure.

- Low Maintenance: Unlike traditional materials that may require frequent staining or painting, ASA co-extruded products retain their appearance with minimal upkeep.

- Durability: The co-extrusion process results in a product that resists cracking, warping, and chemical damage, increase lifespan of your investment.

- Aesthetic Appeal: With a wide range of colors and finishes, ASA co-extruded products offers a modern, high-end look that enhances the visual appeal of any project.

Applications of ASA Co-Extrusion ASA co-extrusion is ideal for a variety of outdoor projects, including:

- Decking: Long-lasting and beautiful, ASA co-extruded decking can face harsh weather while maintaining its color and integrity.

- Siding and Cladding: ASA co-extruded siding provides excellent protection and an attractive appearance for buildings, ensuring long-term performance.

- Fencing: Create durable and stylish fences that resist the elements and maintain their color and strength over time.

Considerations Before Choosing ASA Co-Extrusion

- Budget: While ASA co-extruded products offer long-term savings in maintenance, the initial cost may be higher compared to other materials.

- Environmental Conditions: If your project is in an area with extreme weather, ASA co-extrusion offers unparalleled resistance to fading, cracking, and wear.

- Aesthetic Requirements: If you’re looking for a specific color or finish, ASA co-extruded products provide a wide range of options that hold up over time.

If you need a durable, low-maintenance, and aesthetically pleasing solution for your outdoor projects, ASA co-extrusion might be the perfect choice. Its superior weather resistance and longevity make it an excellent investment for both residential and commercial applications.

ASA co-extrusion Applications

Showcase our different applications, residential, industrial, commercial, public spaces etc.

advertising Board

shop signs

Garder Walls

building exterior walls

Door Signs

Public Place Exterior Walls

Wall cladding

Balcony

Machinery for Efficient Production

We have a large scale of automated production equipment to meet the simultaneous production of a variety of products, no matter the size of your order. In addition to producing WPC decking, WPC wall panels,WPC deck tiles,WPC wall cladding, composite fencing, etc. You can also quickly produce any WPC product to match your project needs.

65 Production Lines for WPC Composite Decking

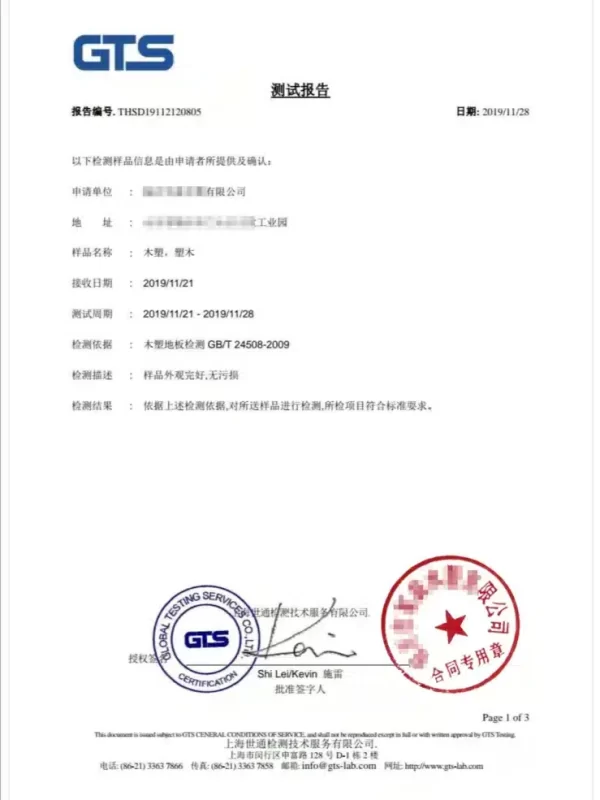

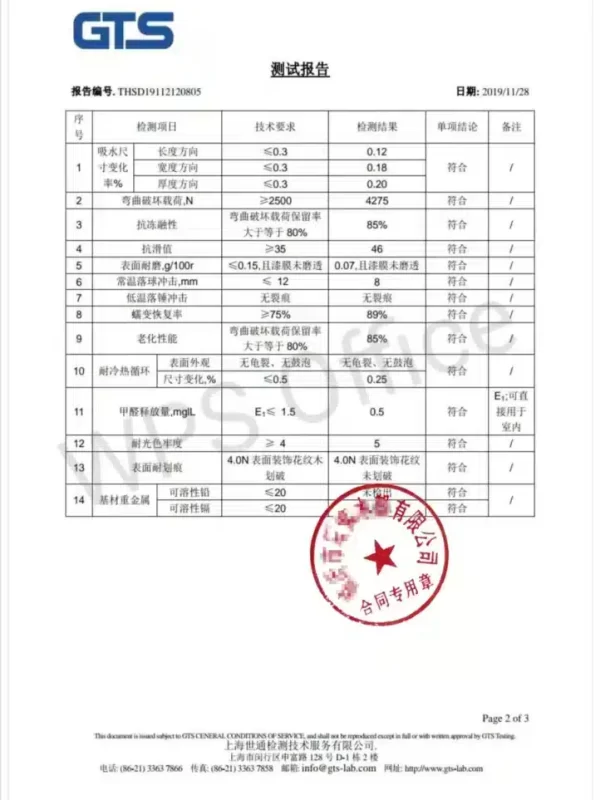

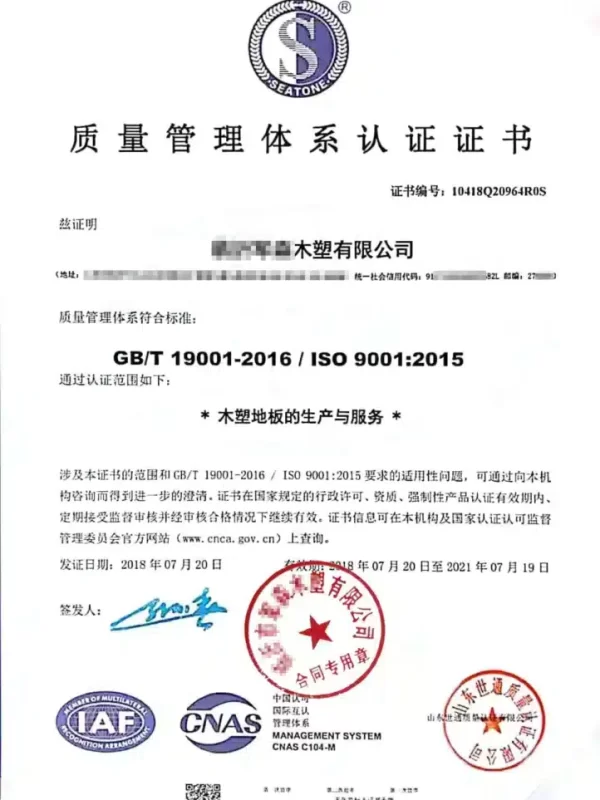

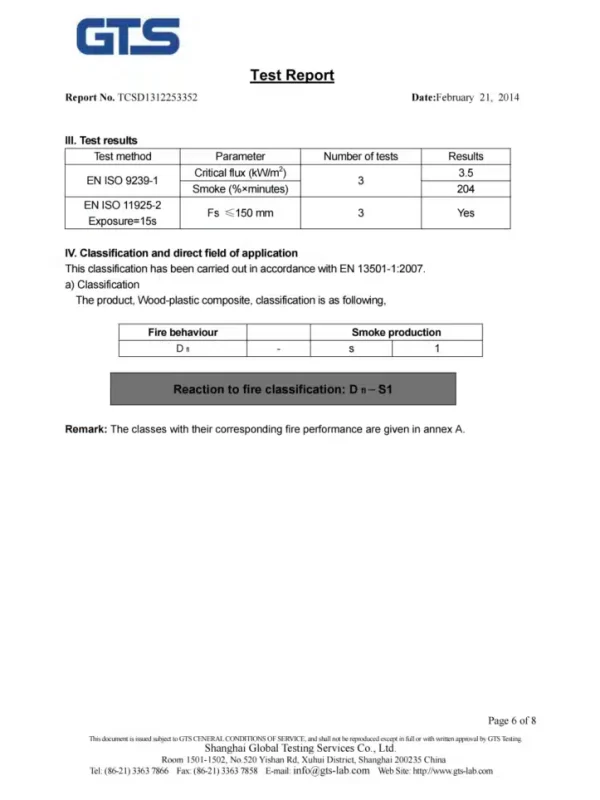

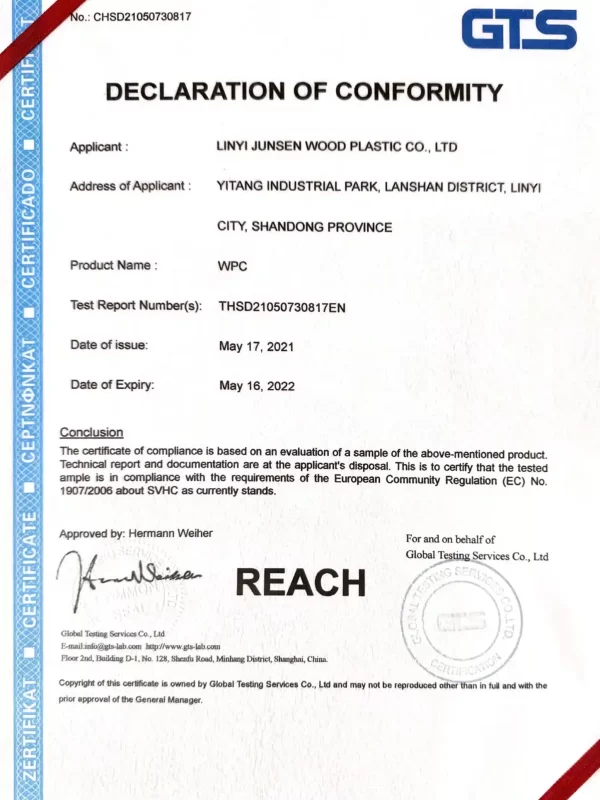

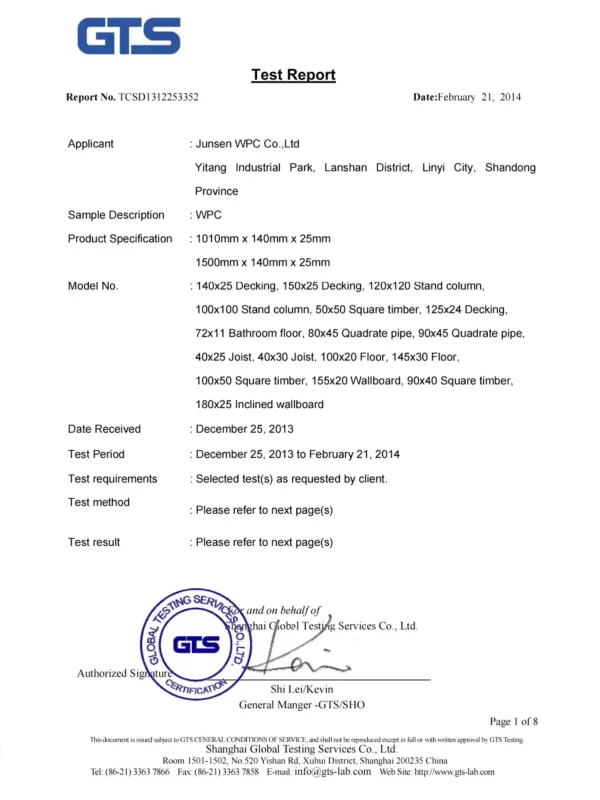

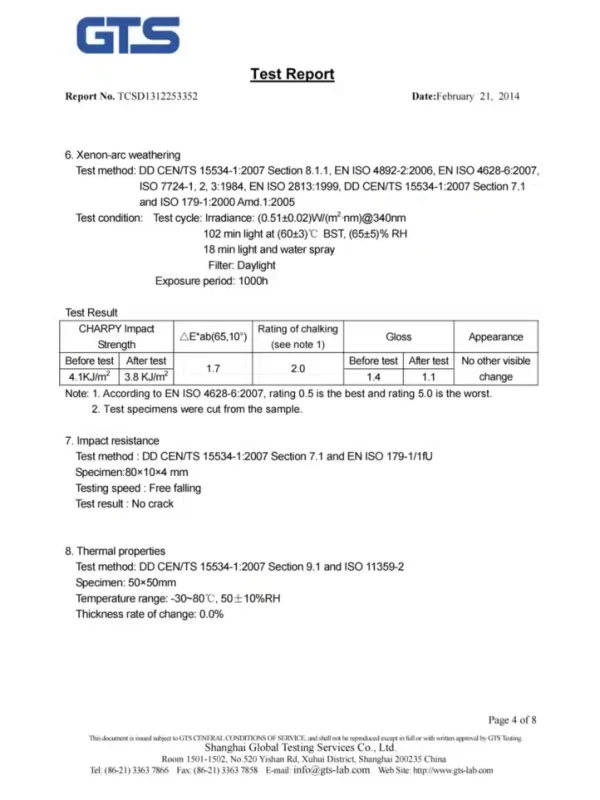

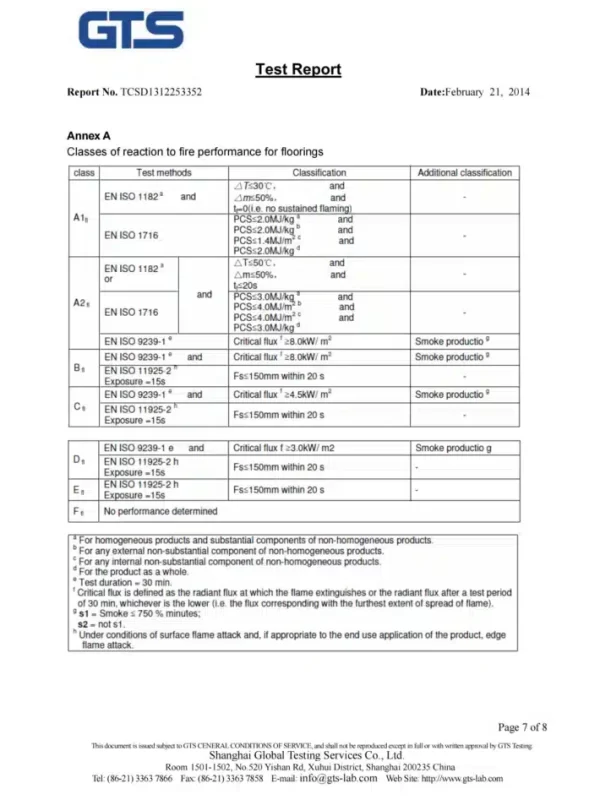

Authoritatively Certified

As our factory complies with ISO quality management requirements, EcoxPlank’s products are made following SGS,CE, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.

TELL US SPECIAL REQUIREMENTS FOR ASA Co-Extrusion

If our standard size or color do not perfectly match your needs, we also offer custom service.

Ecoxplank Blog

The 6 Most Important Technical Indicators of WPC Decking

Should You Source WPC Fence from China?

Swimming Pool WPC Deck: Complete Manufacturer Guide

FREQUENTLY ASKED QUESTIONS

Come Visit Us!

Business Address: No.1214, Block C, Jinhui Global Center, Yanta District, Xi ‘an, Shaanxi, China

Factory Address: Industrial Park, Caoxian County, Heze City, Shandong Province, China

Email: sales@ecoxplank.com

Our team is very friendly and ready to help you with any queryies.

If you would like to send us message, then please fill free to contact us via whatsapp or you can use this form. We will get in touch with you as soon as possible.

Get free samples and prices right now!

EcoxPlank is a leading manufacturer of high performance wood plastic composite (WPC) products in China. Contact us to get free samples. If our standard size do not match for you, we also provide custom service.