WPC Hollow composite decking

Our WPC Hollow Decking Boards has the best combination of natural wood combination also long lasting durability. Can be used for both residential and commercial outdoor projects. It has realistic wood grain texture. These boards are ideal for creating beautiful low maintenence projects.

Type: Hollow Decking

Available Options: Traditional/Capped/Embassed/ASA Co-extrusion

Size: 140×25mm(standard) sizes are customizable

Length: 2.4m, 2.9m, 3.6m, 4m, or customized

Component: 60% wood powder + 35% HDPE + 5% GERMANY IMPORTS BASF

Applications: Residential Deck, Commercial Satios, Pool Surrounds, Walkways, Garden Paths etc.

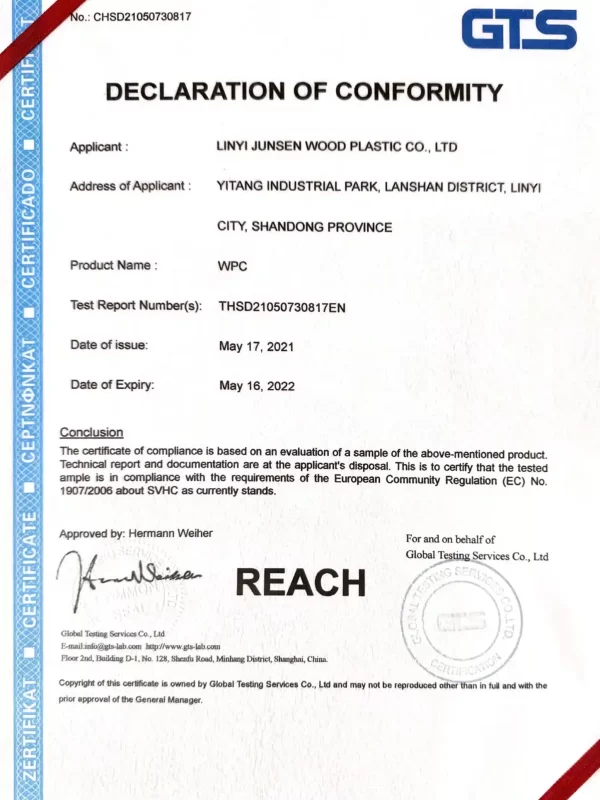

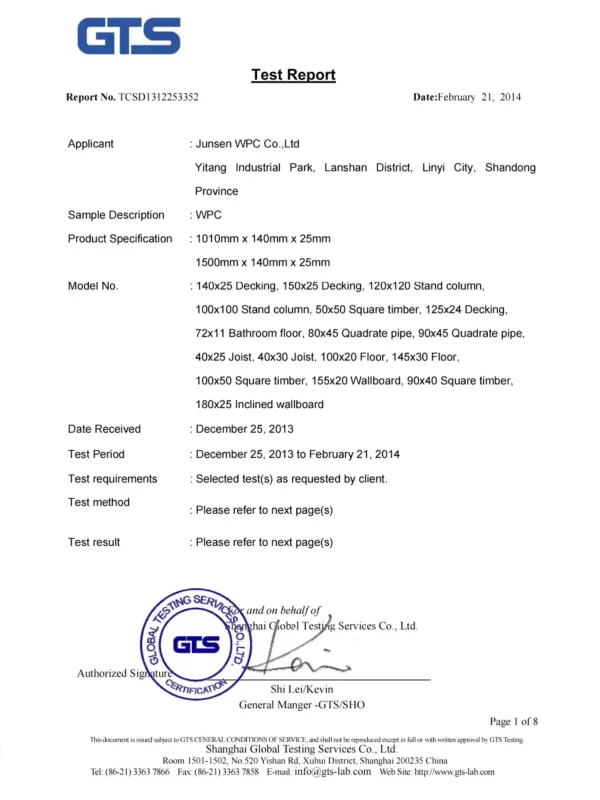

Certificates: SGS,CE, DIN, JIS, GOST and GBSGS,CE, DIN, JIS, GOST and GB

LEADING WPC HOLLOW DECKING MANUFACTURER & SUPPLIER IN CHINA

Wholesale Custom WPC Hollow Decking Boards

Our WPC Hollow Decking Board is available in 8 colors, regardless of thickness, length, panel color, texture can be customized.

Charcoal

Light grey

Grey

Chocolate

Red wood

Wood

Cedar

Coffee

DE146H24 - 3d Embossed WPC Hollow Decking

AS144H22 - WPC Hollow Decking

AS145H22 - WPC Hollow Decking

AS114H19 - WPC Hollow Decking

DE146H25 - 3d Embossed WPC Hollow Decking

CO140H25S - Hollow Capped Decking

CO140H24S - Hollow Capped Decking

CO140H23S - Hollow Capped Decking

embossed WPC decking Wholesale Price

- Embossed WPC decking Price: 12.5 – 32.9USD/SQM

- Minimum Order Quantity: 300㎡ per design & color

What is Hollow WPC Decking?

Our WPC material is made from 60% wood powder + 35% HDPE + 5% .

WPC (Wood Plastic Composite) hollow decking is a type of decking material made from a mixture of wood fibers and plastic. Unlike solid WPC decking, hollow WPC decking has a hollow core, making it lighter and often more cost-effective.

WPC hollow decking is commonly used in outdoor spaces such as patios, balconies, garden paths, and pool areas. It offers a sustainable, low-maintenance alternative to traditional wood decking.

Lightweight

The hollow core reduces the weight of the decking boards, make them easier to carry and install, especially in DIY projects. Reduced weight also leads to lower transportation costs, which can be significant factor for large projects,

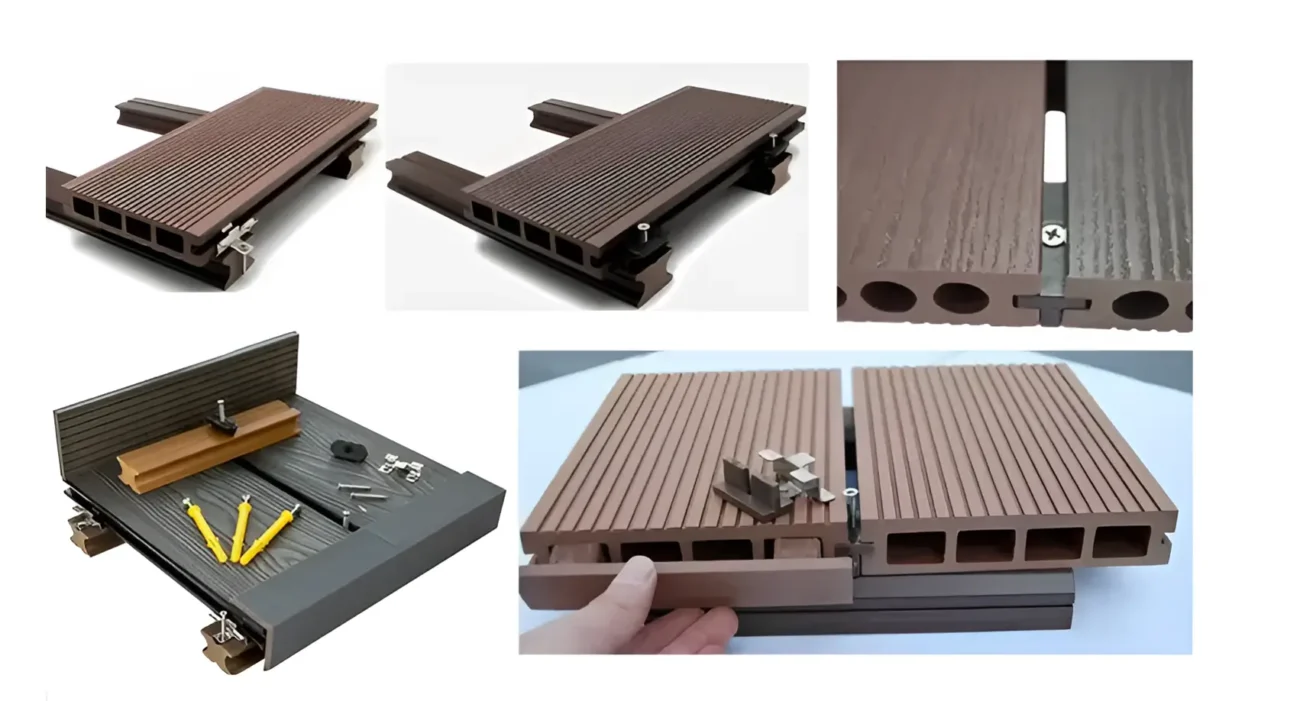

Installation Flexibility

The reduced weight of hollow WPC decking contributes significantly to its ease of installation. Because the boards are lighter, they are easier to position and secure into place. This is especially beneficial in situations where the decking needs to be installed in tight or hard-to-reach spaces, or on uneven surfaces.

Advantages of Hollow WPC Decking Boards

Durability

Highly resistant to rot, decay, and insect damage. It does not warp, crack, or splinter, making it an ideal choice for long-lasting outdoor spaces.

Low Maintenance

Requires less maintenance compared to wood. It does not need to be stained, painted, or sealed, and can be easily cleaned with soap and water.

Eco-Friendly

By using recycled materials, Composite decking is an environmentally friendly option. It helps reduce deforestation and the amount of plastic wastes.

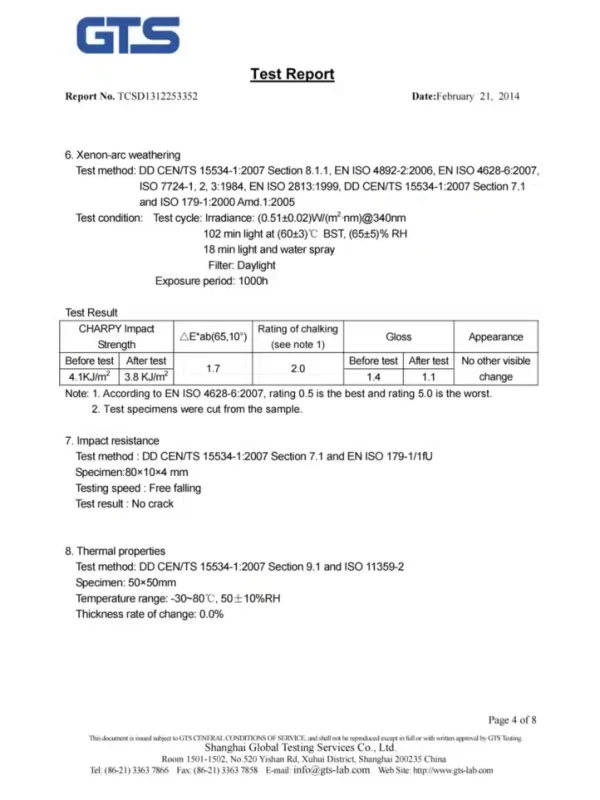

Weather Resistance

Resist various weather conditions, including heavy rain, snow, and intense sunlight. It is resistant to fading and staining, ensuring it maintains its appearance over time.

Anti-slip

This slip-resistant ensures a secure and safe walking experience, even in wet conditions. Ideal for pool surrounds, patios, and walkways.

Aesthetic Appeal

The natural wood grain texture and different color options make any outdoor area look beautiful. These boards are perfect for adding a stylish and attractive touch.

100% Water Resistance

Resistant to moisture, which prevents mold, mildew, and water damage. This feature makes them ideal for areas with high humidity or frequent rainfall.

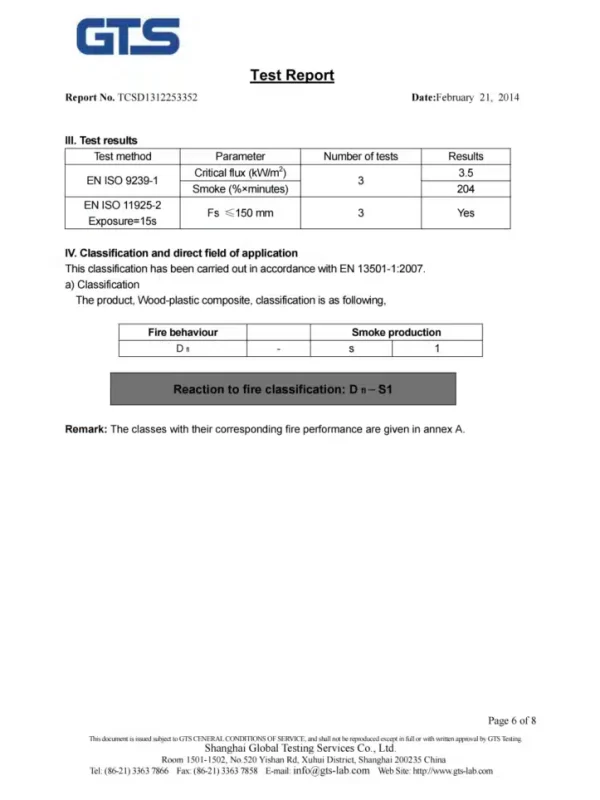

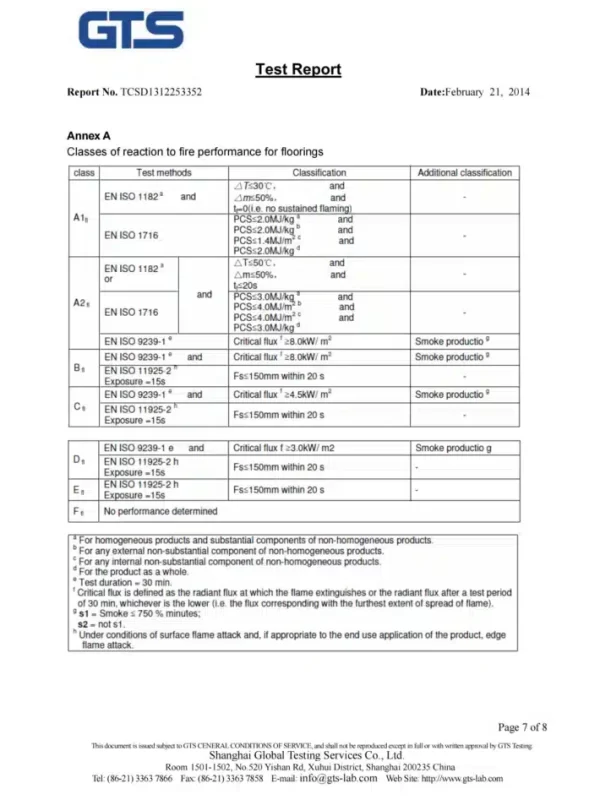

Fire Resistance

With a strong fire resistance and a B fire-proof rating, this material is highly flame-retardant and self-extinguishes if a fire occurs.

No Gap Option

If you are looking for no gap solution. Hollow WPC Decking Board will be a great option. It also extremely easy to fix.

Difference between Hollow vs Solid

Solid Deck Board

- High Strength: Solid boards are stronger and can support more weight.

- Natural Look: They look and feel more like traditional wood.

- Solid Sound: They provide a more solid, quiet sound underfoot.

- Long-lasting: Generally, solid boards have a longer lifespan.

Round Deck Board

- Lightweight: Hollow boards are lighter, making them easier to transport and install.

- Cost-effective: Generally, hollow boards are less expensive than solid boards.

- Cooler Underfoot: Hollow boards can dissipate heat more effectively, staying cooler underfoot in hot weather.

- Easier to Handle They can be easier to cut and handle during installation due to their lower weight.

Square Hollow Deck Board

- Lightweight: Lighter then Circle Hollow Board

- Cost-effective: Cheaper then Round Hollow Deck Board

- Easier to Handle Easier to install then Circle Hollow

- Most Popular: More Widely Used among them.

Colors of products

Charcoal

Light grey

Grey

Chocolate

Red wood

Wood

Cedar

Coffee

Customizable sizes

|

Width |

140mm |

140mm |

200mm |

|

Thickness |

20mm |

22mm |

22mm |

What Our Valuable Partners Say About Us

Solid WPC Decking Applications

Showcase our different applications, residential, industrial, commercial, public spaces etc.

Solid WPC Table Chair

Solid WPC Decking Belcony

Solid Composite Decking Stairs

Solid Composite Decking

Solid outdoor composite decking

Solid indoor composite decking

Solid WPC Belcony

Solid WPC deck stair

Solid WPC Decking

Solid WPC pool decking

Solid WPC Decking

Solid Outdoor decking

Installation Accessories for WPC items

Start Clips

Stainless steel clip

Plastic Clip

Plastic Clip

Expansion screw

Screw

Solid WPC joint

WPC L corner

|

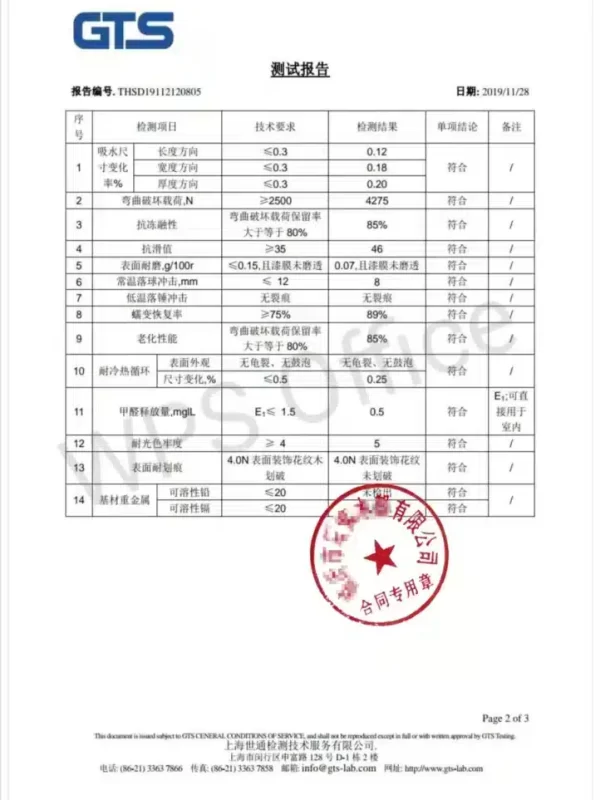

No. |

Inspection Item |

Standard Requirement |

Test Result |

Item Conclusion |

Test Basis |

|---|---|---|---|---|---|

|

1 |

Bending Strength |

≥2500 |

5315 |

Conforming |

GB/T 24508-2020, 6.5.4.1 |

|

2 |

Impact Resistance |

Bending Strength Retention Rate ≥80% |

93% |

Conforming |

GB/T 24508-2020, 6.5.10 |

|

3 |

Low-Temperature Impact |

No Cracks at -10°C |

No Cracks |

Conforming |

GB/T 24508-2020, 6.5.12 |

|

4 |

Constant Temperature Water Absorption |

Water Absorption ≤12% |

7.3% |

Conforming |

GB/T 24508-2020, 6.5.8 |

|

5 |

Density |

≥0.3 g/cm³ |

0.58 g/cm³ |

Conforming |

GB/T 24508-2020, 6.3 |

|

6 |

Surface Hardness |

≥2 |

1.2 |

Conforming |

GB/T 24508-2020, 6.5.3 |

|

7 |

Surface Abrasion |

≤0.15 |

0.15 |

Conforming |

GB/T 24508-2020, 6.5.5 |

|

8 |

Dimensional Stability |

0.62 |

Conforming |

GB/T 24508-2020, 6.5.16 |

|

|

9 |

Thermal Aging Resistance |

After aging, external appearance, color, no cracking, and no peeling |

No change in external appearance, no cracking, and no peeling |

Conforming |

GB/T 24508-2020, 6.5.2 |

|

10 |

Water Absorption Length Direction |

≤0.3% |

<0.1% |

Conforming |

GB/T 24508-2020 (6.5.7) |

| Water Absorption Width Direction |

≤0.3% |

<0.1% |

Conforming |

GB/T 24508-2020 (6.5.7) |

|

|

Water Absorption Thickness Direction |

≤0.5% |

<0.1% |

Conforming |

GB/T 24508-2020 (6.5.7) |

|

|

11 |

Heat Resistance Front, Back |

±1.0% |

0.2% |

Compliant |

GB/T 24508-2020 (6.5.8) |

|

Heat Resistance Dimensional Change Difference |

≤0.5 |

<0.1% |

Compliant |

GB/T 24508-2020 (6.5.8 |

|

|

12 |

Surface Quality Average Value |

≥1 |

1.41 |

Compliant |

GB/T 24508-2020 (6.3.7) |

|

13 |

Cold and Heat Cycle Resistance Surface Appearance |

No cracks, no bubbles |

No cracks, no bubbles |

Compliant |

GB/T 24508-2020 (6.5.9) |

|

Dimensional Change |

≤0.5 |

0.1 |

Compliant |

GB/T 24508-2020 (6.5.9) |

|

Sample Name |

Wood Plastic Decking |

Test Category |

Routine Inspection |

||

|

Commissioning Unit |

Ecoxplank |

Supplier |

Ecoxplank |

||

|

Manufacturer |

Ecoxplank |

Sample Status |

Complete Sample Received |

||

|

Sample Receipt Date |

March 17, 2022 |

Sample Quantity |

20 pieces |

||

|

Production Date/Batch No. |

Model Specification |

140mm×23mm×6000mm |

|||

|

Test Basis |

According to the test methods specified in GB/T 24508-2020 for wood plastic decking. |

Inspection Date |

March 21-23, 2022 |

||

| Judgment Basis |

Wood Plastic Decking GB/T 24508-2020 |

||||

|

Inspection Items |

Full Item Inspection |

||||

|

Inspection Conclusion |

The sample submitted has been tested according to the methods specified in GB/T 24508-2020 for wood plastic decking. All tested items meet the standard requirements. |

||||

|

Date |

April 1, 2022 |

||||

Machinery for Efficient Production

We have a large scale of automated production equipment to meet the simultaneous production of a variety of products, no matter the size of your order. In addition to producing WPC decking, WPC wall panels,WPC deck tiles,WPC wall cladding, composite fencing, etc. You can also quickly produce any WPC product to match your project needs.

65 Production Lines for WPC Composite Decking

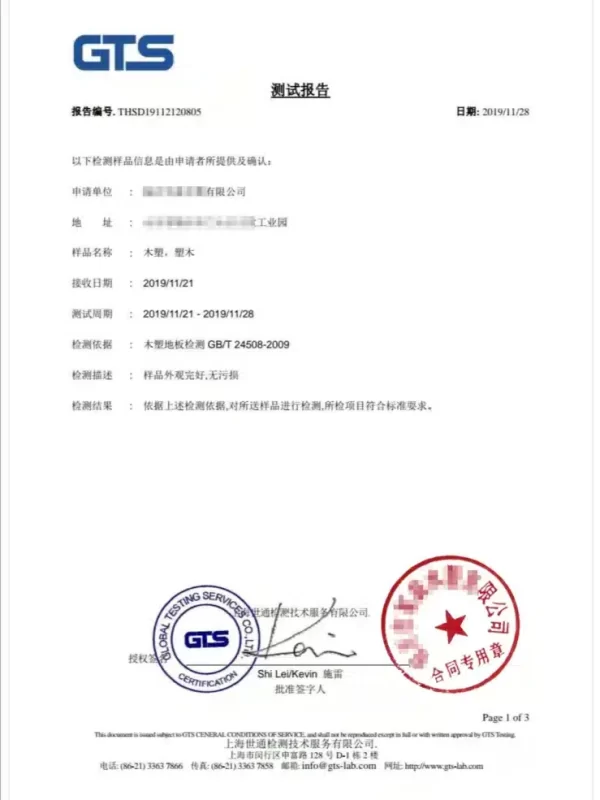

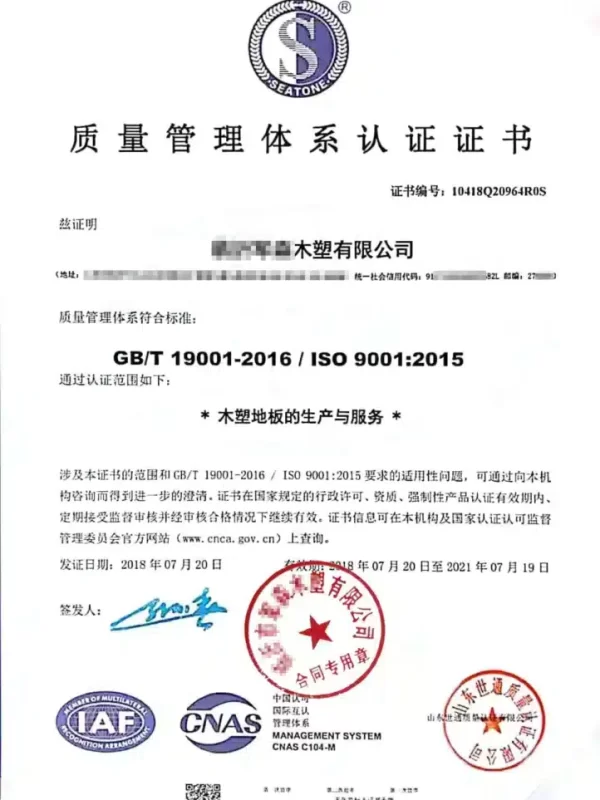

Authoritatively Certified

As our factory complies with ISO quality management requirements, EcoxPlank’s products are made following SGS,CE, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.

TELL US SPECIAL REQUIREMENTS FOR WPC Hollow Decking Boards

If our standard size or color do not perfectly match your needs, we also offer custom service.

Ecoxplank Blog

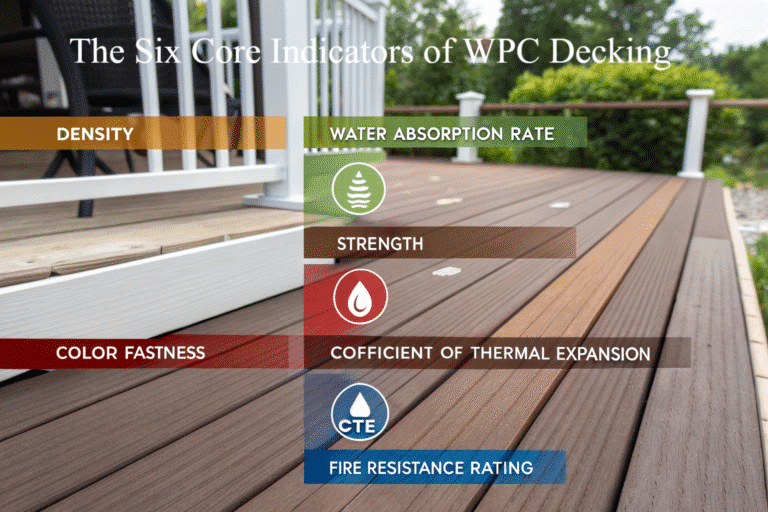

The 6 Most Important Technical Indicators of WPC Decking

Should You Source WPC Fence from China?

Swimming Pool WPC Deck: Complete Manufacturer Guide

FREQUENTLY ASKED QUESTIONS

Come Visit Us!

Business Address: No.1214, Block C, Jinhui Global Center, Yanta District, Xi ‘an, Shaanxi, China

Factory Address: Industrial Park, Caoxian County, Heze City, Shandong Province, China

Email: sales@ecoxplank.com

Our team is very friendly and ready to help you with any queryies.

If you would like to send us message, then please fill free to contact us via whatsapp or you can use this form. We will get in touch with you as soon as possible.

Get free samples and prices right now!

EcoxPlank is a leading manufacturer of high performance wood plastic composite (WPC) products in China. Contact us to get free samples. If our standard size do not match for you, we also provide custom service.