Premium WPC Wall Panel for Lasting Performance

Best WPC Wall Panel Manufacturer & Supplier in China

Ecoxplank WPC Wall Panels, also known as Wood Plastic Wall Panels, Composite Wall Panels, WPC Wall Boards, and WPC Wall Cladding, are designed to enhance the exterior and interior walls of buildings.

When selecting materials for your project, consider the advantages of composite wood wall panels. They are highly durable, low-maintenance, 100% waterproof, splinter-free, eco-friendly, and resistant to harsh weather—features not commonly found in other materials.

Once you decide to use wall paneling, it's important to select the best decorative material available. Ecoxplank composite fencing boards offer an exclusive technological advantage with Xshield, solidifying our reputation as a leading provider in China.

Wholesale Custom WPC Wall Panel

Our Embossed WPC Wall Panel is available in 8 colors, regardless of thickness, length, panel color, texture can be customized.

Charcoal

Light grey

Grey

Chocolate

Red wood

Wood

Cedar

Coffee

WPC Wall Pannel Factory Wholesale Price

- WPC wall cladding Price:11- 17 USD Per sqm

- Minimum order Quantity: 300 square metres per design & color

What is WPC Wall Panel?

A WPC (Wood Plastic Composite) wall panel is a building material made from a combination of wood fibers and plastic. This innovative material is designed to replicate the appearance of natural wood while offering enhanced durability and resistance to environmental factors. WPC wall panels are commonly used for both interior and exterior wall cladding, providing a stylish and low-maintenance alternative to traditional wood or other cladding materials.

WPC wall panels are known for their long-lasting performance, as they are resistant to moisture, termites, and rot. They also require minimal upkeep, making them a popular choice for those looking to achieve a natural wood look without the associated maintenance. Additionally, WPC panels are eco-friendly, as they are often made from recycled materials, and they contribute to energy efficiency by providing insulation.

Ideal for various architectural styles, WPC wall panels are available in a wide range of colors, textures, and finishes, allowing for customization to suit different design preferences. Whether used for residential or commercial projects, WPC wall panels offer a combination of aesthetic appeal, durability, and sustainability.

Ecoxplank is a leading WPC wall panel manufacturer & supplier with 12+ years of experience. Our WPC panel has been sold to 120 countries, such as UK, America, Canada, Australia, Serbia, Panama, Brazil, Qatar, Kuwait, Colombia, Uruguay, Oman, etc. Our factory offer a variety of WPC exterior wall panel comes in different colors, patterns, and lengths.

Where can we use?

WPC (Wood Plastic Composite) wall panels are versatile and suitable for both interior and exterior use. Indoors, they enhance living rooms, kitchens, and bathrooms with their water-resistant and low-maintenance properties. In commercial spaces like offices and restaurants, they offer a modern, durable finish. Outdoors, WPC panels are ideal for residential facades and garden structures, providing weather-resistant, eco-friendly cladding. Whether for decorative or functional purposes, WPC wall panels deliver a stylish and long-lasting solution.

Eco-Friendly Sustainability

WPC wall panels are an environmentally conscious choice, made from a blend of recycled wood fibers and plastic. This sustainable composition not only reduces the need for deforestation but also repurposes plastic waste, contributing to a greener planet. Additionally, WPC panels are recyclable at the end of their lifecycle, making them a truly eco-friendly alternative to traditional building materials.

Advantages of WPC Composite Decking

Durability

Unlike traditional wood, Composite Fencing is highly resistant to rot, decay, and insect damage. It does not warp, crack, or splinter, making it an ideal choice for long-lasting outdoor spaces.

Low Maintenance

Composite Fencing requires less maintenance compared to others. It does not need to be stained, painted, or sealed, and can be easily cleaned with soap and water.

Eco-Friendly

By using recycled materials, Composite Fencing is an environmentally friendly option. It helps reduce deforestation and the amount of plastic wastes.

Weather Resistance

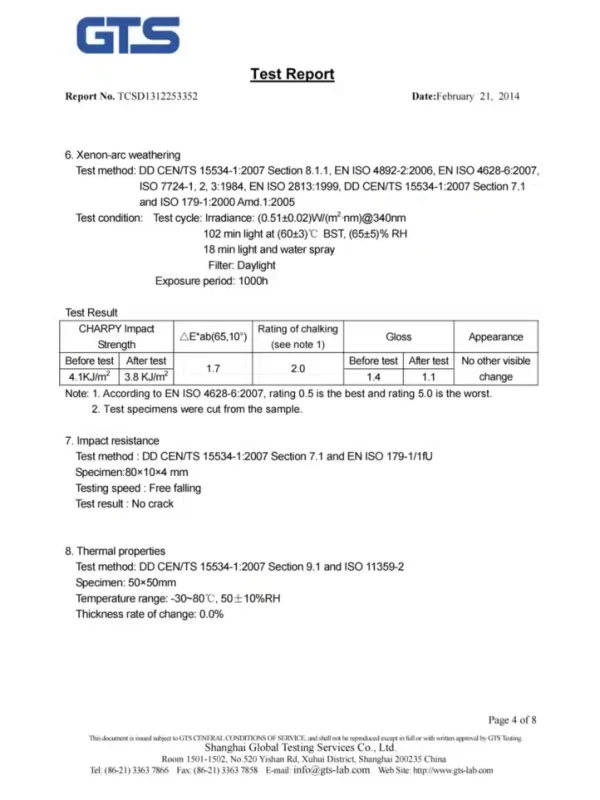

Composite Fencing is designed to withstand various weather conditions, including heavy rain, snow, and intense sunlight. It is resistant to fading and staining, ensuring it maintains its appearance over time.

Aesthetic Appeal

The natural wood grain texture and different color options make any outdoor area look beautiful. These boards are perfect for adding a stylish and attractive touch.

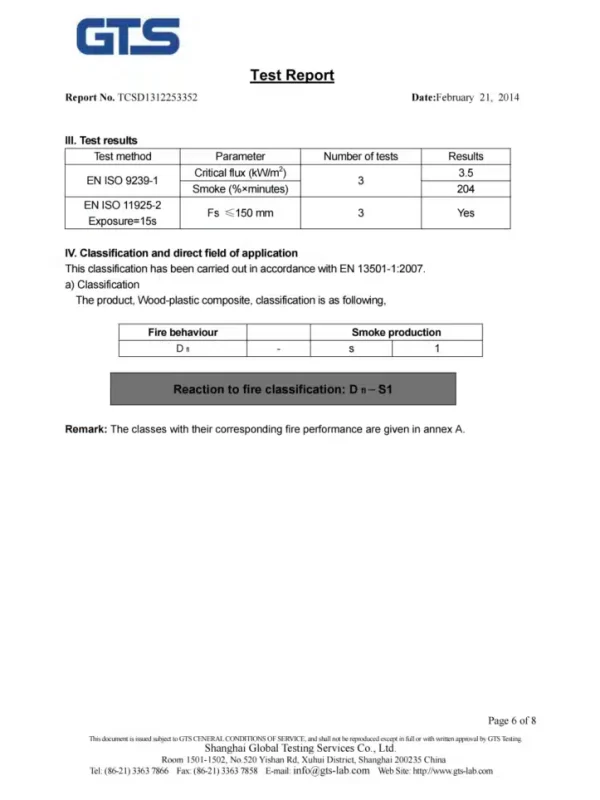

Fire Resistance

The material's high durability is due to its resistance to weathering. WPC is fire and water resistant. Depending on its composition

100% Water Resistance

Resistant to moisture, which prevents mold, mildew, and water damage. This feature makes them ideal for areas with high humidity or frequent rainfall.

Sound Insulation

They offer good sound insulation properties, making them suitable for both residential and commercial spaces.

Is WPC Wall panel stronger than wood?

Yes, WPC (Wood Plastic Composite) wall panels are generally stronger and more durable than traditional wood. Here’s how:

1. Enhanced Durability: WPC panels are engineered to withstand harsh environmental conditions better than wood. They are resistant to moisture, termites, rot, and warping, making them more durable and long-lasting.

2. Impact Resistance: WPC panels typically have better impact resistance compared to wood. They are less likely to dent or crack under pressure, which contributes to their overall strength and longevity.

3. Weather Resistance: WPC panels are designed to endure extreme weather conditions, including UV exposure, rain, and temperature fluctuations, without significant degradation. This makes them more resilient than traditional wood, which can warp, crack, or fade over time.

4. Low Maintenance: While wood often requires regular maintenance and treatments to retain its strength and appearance, WPC panels need minimal upkeep. Their resistance to environmental factors reduces the need for frequent repairs or replacements.

Overall, WPC wall panels offer a combination of strength, durability, and low maintenance that typically surpasses that of traditional wood.

Which is better, PVC or WPC?

WPC offers a more natural appearance and better long-term durability.

WPC has the advantage of being more eco-friendly.

WPC Tube Applications

Showcase our different applications, residential, industrial, commercial, public spaces etc.

WPC Tube exterior wall

WPC Tube Decorative

WPC Tube Pergola

Composite Tube Exterior

Composite Tube Pergola

WPC Tube Parking Structures

WPC Pergola for Outdoor Living Spaces

WPC Balcony Pergola

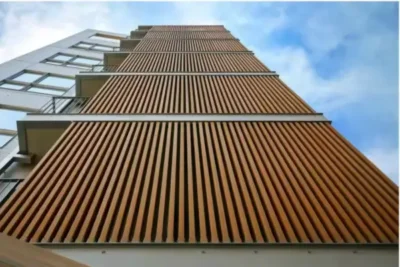

WPC Vertical Slat Facade for Modern Exteriors

WPC Brise Soleil for Shading and Privacy

WPC Rooftop Pergola for Outdoor Lounging

WPC Vertical Facade Cladding for High-Rise Buildings

Machinery for Efficient Production

We have a large scale of automated production equipment to meet the simultaneous production of a variety of products, no matter the size of your order. In addition to producing WPC decking, WPC wall panels,WPC deck tiles,WPC wall cladding, composite fencing, etc. You can also quickly produce any WPC product to match your project needs.

65 Production Lines for WPC Composite Decking

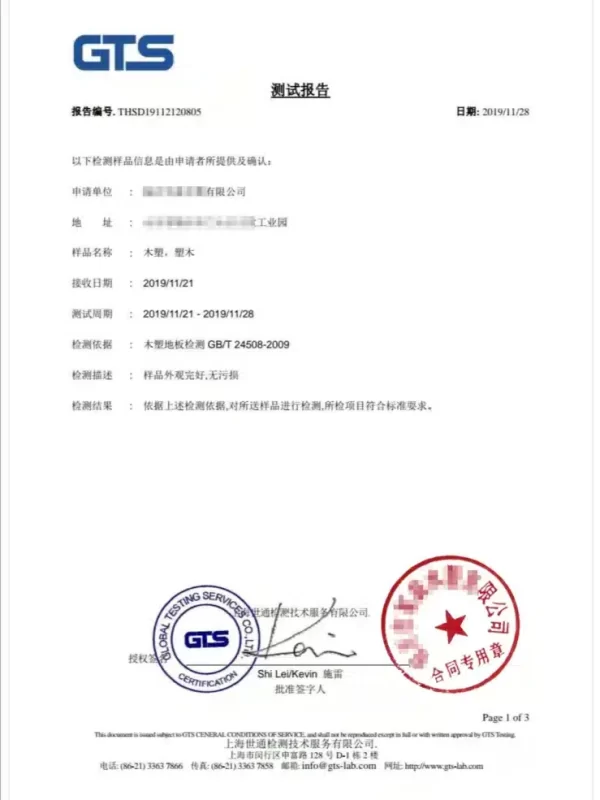

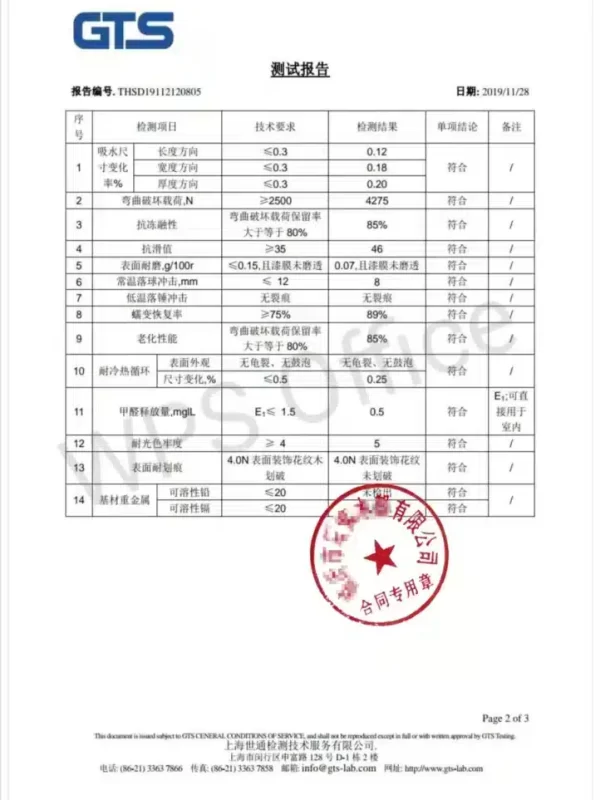

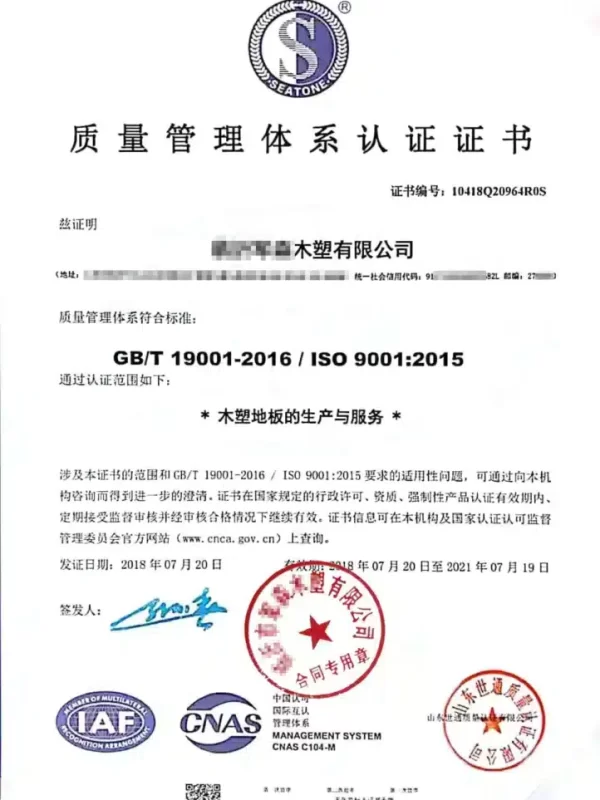

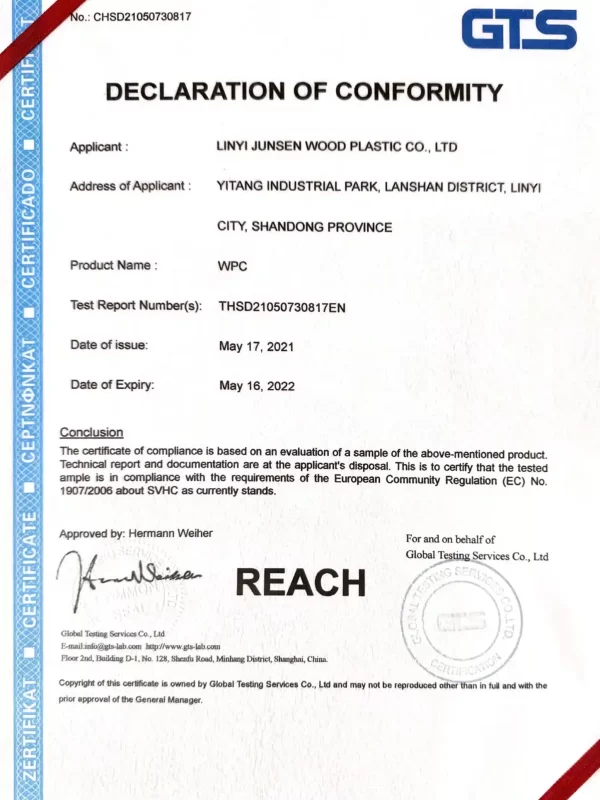

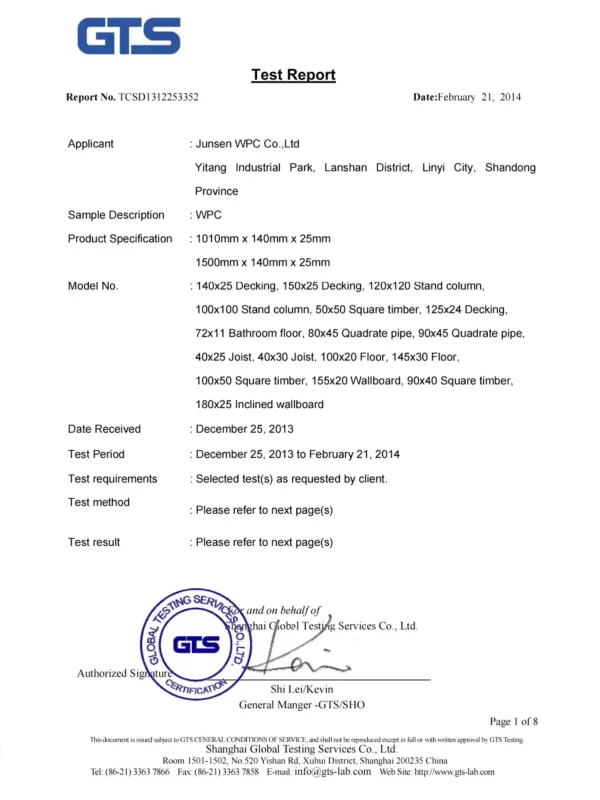

Authoritatively Certified

As our factory complies with ISO quality management requirements, EcoxPlank’s products are made following SGS,CE, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.

Ecoxplank Blog

The 6 Most Important Technical Indicators of WPC Decking

Should You Source WPC Fence from China?

Swimming Pool WPC Deck: Complete Manufacturer Guide

FREQUENTLY ASKED QUESTIONS

Come Visit Us!

Business Address: No.1214, Block C, Jinhui Global Center, Yanta District, Xi ‘an, Shaanxi, China

Factory Address: Industrial Park, Caoxian County, Heze City, Shandong Province, China

Email: sales@ecoxplank.com

Our team is very friendly and ready to help you with any queryies.

If you would like to send us message, then please fill free to contact us via whatsapp or you can use this form. We will get in touch with you as soon as possible.

Get free samples and prices right now!

EcoxPlank is a leading manufacturer of high performance wood plastic composite (WPC) products in China. Contact us to get free samples. If our standard size do not match for you, we also provide custom service.