Quality Consciousness

We take pride in producing high quality WPC products

We are well aware of the importance of product quality to the success of our brand, and Ecoxplank attaches great importance to maintaining high quality standards in the production and service of our WPC range.

We invest both human and financial resources to produce super durable product quality for our users, and we always do our best to produce reliable WPC products that exceed global certification requirements.

5

Ecoxplank WPC (wood plastic composite) Quality control SOP process

1. Customer focus

Ecoxplank’s quality team aims to deliver quality standards that meet and exceed international market expectations.

2. Standard

Ecoxplank’s quality control team maintains strict control over routine product inspections throughout the production process. And, we implement the responsibility to the people, strictly control every link of production details.

3. Team management

We are committed to excellence and our quality control encourages the detection of quality issues in the production process. And in accordance with internationally recognized standards.

4. Optimization and improvement

Continuous improvement of composite material manufacturing standards through in-depth quality feedback and market research.

5. Customer relationship management

Establish long-term and stable relationships with our supplier base and network partners to ensure high quality product output and competitive market standards.

Make things better

In order to provide our customers with products they can rely on, we take additional steps to improve our processes, services and company culture.

WPC quality control team

We have assembled a rigorous quality team spread over 8 shipping steps, who will ensure the high quality delivery of our WPC products in accordance with customer standards and global standards.

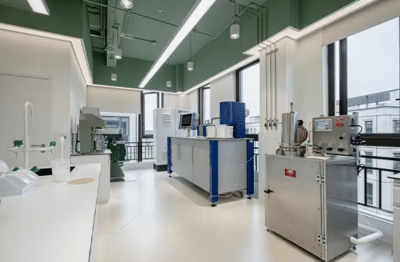

WPC Testing Laboratory

It is equipped with a professional laboratory for testing materials and verifying material properties. We also collaborate with third-party testing organizations to develop and test new material properties.

Independently developed WPC formula

Self-developed unique formula, with special functional modifiers blend modified wood plastic composite material.

The lowest cost strategy is to choose a reliable Ecoxnplank WPC products.

Ecoxplank has experienced specialists specializing in the manufacture of WPC composites and provides technical support and one-stop solutions for the global market.