Composite Decking Accessories: Your Ultimate Configuration Guide

As a mainstream material for outdoor decking, composite decking offers the advantages of being environmentally friendly, durable, and low-maintenance. However, its system performance highly depends on professional accessories. Composite decking accessories play a decisive role in the structural stability, safety, and aesthetics of the decking system. Correct selection and configuration can significantly extend the decking’s lifespan and enhance the quality of the space.

Decking accessories mainly include: composite decking joists, hidden deck fasteners, composite decking screws, composite decking edge trim, composite decking fascia boards, deck lighting systems, composite decking stairs, etc. To create a perfect, durable, and safe composite decking platform, these "accessories" play a vital role and are indispensable components.

This article will delve into the main composite decking accessories, detailing their functions, materials, matching ratios with the main material, installation points, etc., to help you comprehensively understand how to utilize these "accessories" to achieve a perfect outdoor living space.

Composite Decking Joists

Function:

Used to support composite decking boards and transfer loads to beams, posts, and foundations. This allows the decking to remain flat and stable, preventing warping and cracking.

Material:

Mainstream joists primarily include wood joists, WPC joists (made from composite materials with formulations similar to composite decking or PVC materials, designed to provide an "all-composite" system with durability matching the decking), and steel joists (made from cold-formed thin-walled galvanized steel).

Comparison of Different Joist Materials:

| Comparison Item | Wood Joists | WPC/PVC Joists | Steel Joists |

|---|---|---|---|

| Material Type | Pressure-treated natural wood (such as pine, fir) | Wood flour/fiber and plastic (PE/PP/PVC) composite material, or pure PVC | Cold-formed galvanized steel |

| Relative Cost | Low | High | Between wood and WPC |

| Durability (Rot/Insect Resistance) | Good (after treatment), but lifespan is limited, will eventually rot | Excellent, almost immune | Excellent, immune |

| Structural Performance (Stiffness/Span) | Good, meets standard residential span requirements | Lower, allows for smaller spans, requires more support | Excellent, high strength, can achieve large spans |

| Stability | Poor, easily absorbs moisture, deforms, warps, cracks | Excellent, not affected by moisture | Excellent, very stable, does not deform |

| Installation Complexity | Lowest, most mature technology, common tools | Medium, requires strict adherence to manufacturer’s specifications (span, expansion joints, fastening), high technical requirements | High, requires different tools and skills (metal cutting, self-tapping screws), requires specialized knowledge |

| Thermal Expansion/Contraction | Medium | Significant | Low |

| Relative Weight | Medium | Heavy | Lighter for the same strength |

| Maintainability | Requires protection (such as joist tape), potential replacement required | Very low | Low (primarily inspect the galvanized layer and protect cut edges) |

| Advantages | Low cost, mature technology, easy to install, materials readily available | Rot and insect resistant, dimensionally stable, suitable for extremely humid environments | Extremely high dimensional stability, high strength, large spans possible, non-combustible, rot and insect resistant |

| Disadvantages | Short lifespan, prone to deformation affecting flatness, long-term risk of rot | Higher cost, structural span limitations, significant thermal expansion/contraction issues, strict installation requirements | Higher cost than wood, requires specialized tools and skills, cut/drilled areas need rust protection |

| Key Considerations for Composite Decking Compatibility | Strongly recommended to use joist flashing tape, use stainless steel deck screws, adhere to composite decking joist spacing requirements | Strictly follow manufacturer’s installation guidelines, accurately calculate and provide for expansion joints, use specified fasteners | Use dedicated deck screws (with self-drilling tips), cut ends must be rust-proofed, be careful of galvanic corrosion |

| Best Application Scenarios | Standard budget projects, dry or well-drained environments | Ground-level decking, docks, pool surroundings, projects requiring maximum lifespan and sufficient budget | Areas with high fire resistance requirements, areas prone to termites, projects requiring high stability |

Ratio (Matching with Main Material):

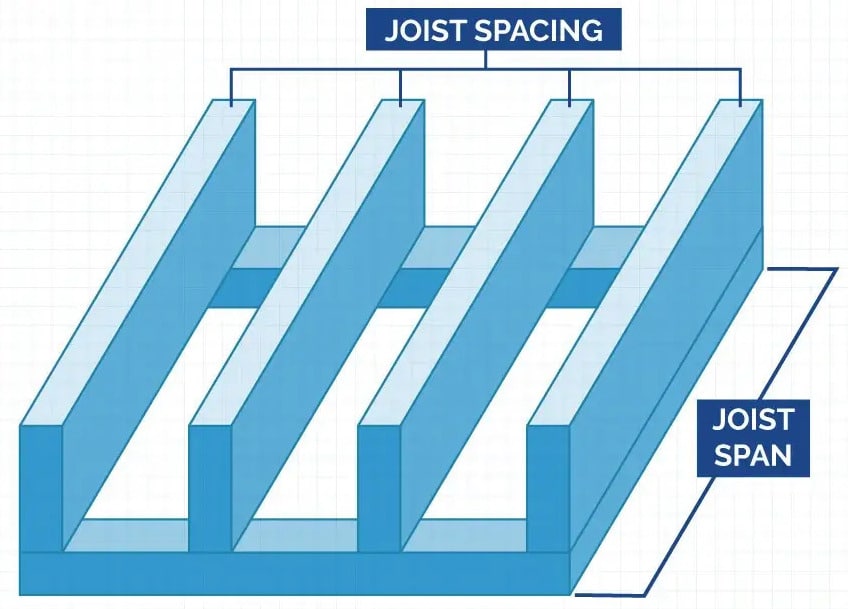

When discussing the "ratio" of composite decking to joists, the most practical and crucial metric is the composite decking joist spacing. This determines how many linear units of joist are needed per square unit of decking for support.

Regarding composite decking joist spacing, it primarily depends on the specific decking product you choose. The most common standard is 16 inches (approx. 406 mm) on center, suitable for most residential and perpendicular installations. However, for commercial heavy loads, diagonal installations, or when using certain specific or thicker decking boards, spacing often needs to be reduced to 12 inches (approx. 305 mm) to ensure adequate support. Therefore, the most accurate approach is to consult the official installation guide for the specific decking model you plan to use. It will provide clear requirements, ensuring optimal performance and warranty validity.

Once the joist spacing is known, you can calculate the total length of joists needed for a specific decking area. For example, a 10 ft x 10 ft deck using 16-inch spacing would roughly require (10 ft / (16/12) ft) + 1 = 7.5 + 1 ≈ 9 joists, each 10 feet long (plus edge joists and possible extra blocking). If using 12-inch spacing, it would require (10 / (12/12)) + 1 = 11 joists.

Hidden Deck Fasteners (Clips)

Function:

Hidden deck fasteners are one of the most common accessories in composite decking installation. Their core function is to secure the boards from the side groove or underneath, leaving the decking surface free of visible screw heads. This not only creates an extremely smooth, clean, high-end seamless visual effect but more importantly, enhances comfort and safety – people can walk barefoot without worrying about stepping on or tripping over raised screws.

Material:

Decking clips are typically made from high-grade stainless steel (like 304 or 316 grade) or specially treated engineering plastics with high strength and UV resistance. Stainless steel clips offer high strength, while plastic clips are slightly lower in cost and often easier to install.

Types:

There are various types of decking clips on the market, such as insert-style clips, clip-and-screw types, etc. They need to precisely match the grooved edge design of specific brands and models of decking boards. Compatibility between the clips and the chosen decking must be confirmed during selection.

Ratio (Matching with Main Material):

The quantity needed primarily depends on the joist spacing beneath the decking and the decking width. Standard practice is to install one deck fastener at each intersection point where a decking board crosses a joist. Special composite decking starter clips and composite decking end clips are needed for surface-fixing the first and last boards. The precise quantity should reference the manufacturer’s installation guide, considering the thermal expansion and contraction needs of the boards. Typically, about 21 clips are configured per square meter of decking.

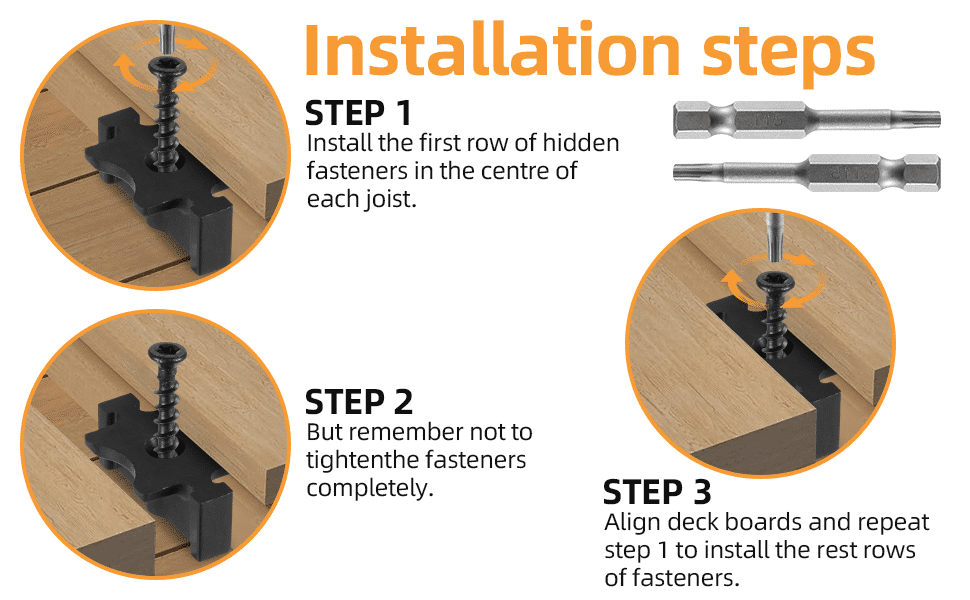

How to Install Decking Clips:

Installation usually involves first sliding or clipping part of the fastener into the side groove of the previously laid decking board. Then, use the provided screw (usually a self-tapping stainless steel screw) to firmly fix the clip onto the underlying joist. Next, align the groove of the subsequent board with the other part of the clip and push it in until it locks securely.

Composite Decking Screws

Function:

Although hidden fasteners are mainstream, using specially designed composite deck screws for face-fastening is still the optimal choice in certain specific situations. These include: installing start and end boards; securing stair treads and risers; installing solid-edge boards without side grooves; and in areas requiring additional reinforcement (like high-traffic zones or uniquely cut shapes).

Material:

Screws with excellent anti-corrosion and anti-rust properties must be chosen. Common options are stainless steel screws (305 or 316 grade) or high-strength carbon steel screws treated with special coatings (like epoxy resin, ceramic coating). Inferior screws will rust quickly, not only affecting aesthetics but also staining the boards and potentially compromising structural stability.

Types:

Composite decking specific screws typically feature: ① A smaller head to minimize visual disruption on the board surface; ② Special thread designs (like double threads, cutting tips) for easier driving into denser composite materials, reducing the risk of board cracking; ③ Common drive types are Star Drive / Torx, which offer better torque transfer than Phillips or flat heads, reducing cam-out and easing installation.

Ratio (Matching with Main Material):

For face-fastening, it’s generally recommended to drive two screws symmetrically at each intersection of the decking board and the underlying joist, about 1 inch (2.5 cm) from the board edge. Specific spacing and quantity should follow the manufacturer’s recommendations.

How to Install:

It’s recommended to use an impact driver or a drill with torque control. For particularly hard or dense composite boards (especially PVC), pre-drilling a Pilot Hole can make screw insertion easier and prevent edge bulging or cracking. Ensure screws are driven vertically and set the head flush with or slightly below the board surface, avoiding over-driving or protrusion.

Fascia Boards / Rim Joist Covers

Function:

After the composite decking platform is built, the surrounding Rim Joists (/End Joists) are exposed. The main function of fascia boards is to cover these, serving both decorative and protective roles. They conceal the relatively untidy joists, providing a complete, smooth vertical finish that matches the decking surface material and color, greatly enhancing the overall aesthetics and premium feel of the deck.

Material:

Composite fascia boards belong to the same series as the decking, made from the same composite material, although generally thinner. They must match the decking’s color and texture, or be customized according to individual needs.

Ratio (Matching with Main Material):

Calculate the total perimeter length and area of the decking to be covered. Account for cutting waste, typically reserving 5%-10%.

How to Install composite decking fascia boards:

Use Fascia Screws specifically designed for fascia boards, which have smaller heads. These screws often have special thread designs to accommodate the thinner profile and potentially larger thermal movement of fascia boards. During installation, expansion gaps must be strictly left according to the manufacturer’s requirements (usually at board ends and joints) to prevent warping or damage due to thermal expansion and contraction. Screw spacing must also follow specifications, typically one screw vertically every 12 inches or so.

How to Install composite decking fascia boards

Composite Decking Edge Trim

Function:

Edge trim for composite decking is primarily used to cover the edges of the decking, the seams between decking and Fascia Boards, and exposed ends or sides on stairs or other transitions. Its core role involves deck edging, enhancing aesthetics, providing a clean and tidy visual effect, while hiding the decking’s internal structure. Additionally, it protects decking ends from damage and wear, and creates smoother, safer edges, which is particularly crucial in stair applications.

Material:

Composite decking trim is usually made of the same material as the decking or fascia boards to ensure a perfect match in color, texture, and performance. Aluminum alloy edges can also be used for modern designs but are less common.

Ratio (Matching with Main Material):

Typically, 1 linear unit of edge trim is allocated for every 10 linear units of decking. For example, if the total composite decking length is 100 feet, then 10 feet of composite decking edge trim would be allocated. Alternatively, a somewhat clever approach involves installers ripping fascia boards lengthwise into narrow strips matching (or slightly wider than) the decking board thickness. These strips are then installed on the outer edge of the decking to cover ends or side grooves. This allows for efficient use of fascia board offcuts, thus saving costs.

How to Install Composite Decking Edge Trim:

The installation of the edge trim of the composite deck is similar to the installation of the fascia board, which can be referred to the video above

But here’s the thing that needs special attention ,fastening is critical when installing composite decking edge trim. High-quality specialized screws should be used, following the manufacturer’s recommended method (e.g., angled driving or fastening from the top edge) to secure it to the frame or the decking itself. Never rely solely on adhesive, and avoid driving directly into the thin edge of a cut face. Due to the linear expansion and contraction of composite materials, adequate gaps must be left at joints and points of contact with posts, walls, etc., to prevent warping; mitered edge trims require particularly precise installation. Edge trim requires a solid support structure, typically fixed to the rim joist or specially installed blocking.

Deck Lighting System

Function:

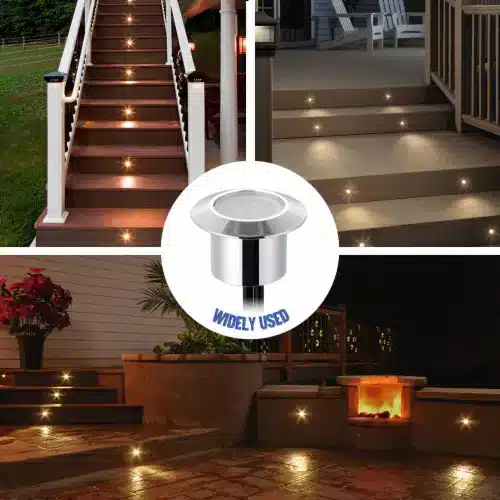

Lighted decks can create outdoor ambiance, enhance nighttime usability, and improve safety. A deck lighting system allows deck lights to be cleverly integrated into various parts of the deck, such as railing post caps, post sides, stair risers, step edges, or even embedded directly into the decking surface or under railings, achieving a professional "light without seeing the source" effect.

System Components:

A deck lighting system consists of three parts: deck lights, power supply, and control unit. Deck lights can be solar deck lights (eliminating the need for a power supply and saving energy) or use efficient, energy-saving low voltage led light, such as led deck lighting strips, deck post lights, deck riser lights. The power supply uses 12V or 24V low voltage for outdoor safety, equipped with waterproof and voltage-stabilizing devices for stable operation. Control methods vary: basic systems use switches, while advanced systems support dimming for scene-based brightness adjustment (e.g., brighter for parties, dimmer for relaxation). Smarter versions can be remotely controlled via smartphone apps for timed switching or automation, enhancing convenience and atmosphere.

Design Points:

Deck lighting ideas need rational layout based on function. Leisure and dining areas require ample light, while pathways and stairs need continuous, shadow-free illumination for safety. Fixture appearance should coordinate with the decking style; for example, wood-grain decking can pair with simple wood-tone fixtures for natural integration. Due to the outdoor environment, the deck lighting system must have excellent waterproof performance. Fixtures should be rated IP65 or higher, and power supplies and connections must be strictly sealed against rain and moisture intrusion to prevent failures and ensure long-term stability.

How to Install:

The main installation methods for outdoor deck light include:

- Surface mounting (e.g., channel-mounted LED strips), suitable for decking edges or where prominent lighting is desired, offering easy installation.

- Recessed mounting (pre-drilling holes so fixtures are flush with the decking), providing even light and a cleaner look, suitable for general lighting in the main decking area.

- Combination mounting (using both recessed and surface methods), e.g., embedding lights in stair treads for safety while adding light strips to handrails for guidance. Flexible combinations can balance functionality and aesthetics.

Composite Decking Stairs

Function:

Composite decking stairs connect multi-level decks or decks at different heights. For decks elevated significantly off the ground (typically over 30 inches, depending on local codes), installing a deck hand railing is a mandatory safety requirement.

Structural Components:

Composite deck stairs consist of treads, risers, and deck handrail. The material, color, and style of these three components should coordinate with the main decking area. Treads are typically 2-3 cm thick to ensure sufficient strength to bear weight. Their surface should feature special textures, like wood grain or matte finishes, to enhance slip resistance and user safety. Risers connect between treads, providing vertical support and enclosing the stair space, usually 15-20 cm high. Handrails provide grip support for users, ensuring safe passage. Balusters are installed on the sides of the stairs for protection. They can be made from the composite decking material itself for a unified look, or combined with other materials like metal or glass for richer design effects.

Composite Decking Stair Installation:

The composite decking stair installation process involves three steps:

- Foundation Preparation: Clear the construction area, locate and mark the outline according to plans, ensure the ground is level and solid, leveling or pouring concrete reinforcement if necessary.

- Tread and Riser Installation: Fix treads and risers sequentially from bottom to top using specialized fasteners, ensuring secure connections. Use a level to verify vertical and horizontal alignment of all components.

- Deck Hand Railing Installation: Set handrails at a height of 80-100 cm. After fixing the handrail, install balusters. Baluster spacing must be ≤11 cm to meet safety codes. The entire process must consider both structural stability and fall prevention safety requirements.

Other Accessories

Composite Decking End Caps

Composite decking end caps are accessories specifically designed for hollow-core decking or boards with scalloped undersides. Their core purpose is to cover the exposed internal cavities after cutting, enhance the end appearance for a clean finish, and somewhat prevent debris ingress. They are not applicable to solid decking or installations already using edge trim. When selecting, the end cap’s profile and color must precisely match the specific decking model; otherwise, installation will fail or look poor. The material is usually plastic or a composite similar to the decking to ensure consistency in appearance and weather resistance. Installation typically relies on a friction fit, but to prevent loosening due to thermal expansion/contraction or vibration, using a small amount of compatible adhesive for auxiliary fixing is strongly recommended. As alternatives, using the same decking boards to picture-frame the perimeter, using ripped fascia board strips for edging, or using dedicated edge trim can completely eliminate the need for end caps, often resulting in a better, more robust, and longer-lasting finish. Therefore, if end caps are chosen for a project, it’s advisable to purchase spares initially and pay close attention to the correct installation method.

Composite Decking End Caps Installation

Feature Strip

Composite decking feature strips are narrow profiles, much thinner than standard boards, primarily serving as high-end decorative elements. They are inlaid between standard boards or used to outline borders and create patterns. Through color or texture contrast, they significantly enhance the decking’s visual hierarchy, design appeal, and personalization, breaking the monotony of large, uniform surfaces. Application scenarios include defining zones, embedding custom patterns, creating color/texture contrast, etc. To ensure long-term performance, the feature strip material must be highly compatible with the main decking material, possessing similar physical properties (like thermal expansion rate). However, using feature strips comes with significant challenges and costs. Their installation is extremely complex, demanding high precision, significant labor time, and advanced installer skills. They often require special fasteners or high-quality adhesives, leading to a substantial increase in labor costs. Despite offering unparalleled aesthetic enhancement and customization, their high overall cost, demanding installation requirements, and potential long-term maintenance issues are key drawbacks. Consequently, feature strips are typically used only in high-end custom projects with ample budgets and require execution by experienced professional teams. They are not usually recommended for projects prioritizing cost-effectiveness and ease of installation.

Drainage Systems

If the space beneath your deck needs to stay dry (e.g., for a lower patio or storage area), a specialized under-deck drainage system or waterproof membrane needs to be installed between the deck joists. These systems collect rainwater that falls through the decking gaps and channel it away to gutters.

Conclusion

Composite decking accessories are core elements in creating high-quality outdoor spaces. From fasteners and screws ensuring stability, railings guaranteeing safety, to edge trims and lighting enhancing aesthetics, each accessory plays a crucial role. Selecting high-quality accessories that match the main material and strictly adhering to professional installation standards effectively ensures the platform’s structural stability and durability. Quality accessories not only improve spatial function and safety but also add aesthetic value, transforming outdoor areas into lasting, comfortable leisure spaces.

More Resourses:

composite decking joist spacing—plasticinehouse

galvanic corrosion —wikipedia

epoxy resin—wikipedia

IP65—https://www.candtsolution.com/news_events-detail/what-is-ip65-rating/

3 thoughts on “Composite Decking Accessories: Your Ultimate Configuration Guide”

Yo, cwin555 is on my radar now! Signed up last week and the vibe is solid. Quick payouts and pretty good selection of games. Feels good so far! You can find them at cwin555.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Righto, 7clubslot looks like a good place to spin some reels. Decent promos too! Take a gander here: 7clubslot

Comments are closed.