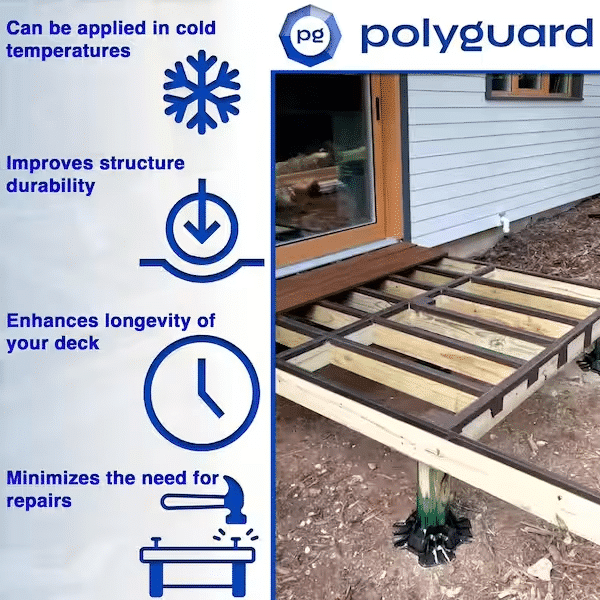

Deck Joist Tape: Protect Your Deck’s Substructure and Prevent Costly Repairs

Deck owners often overlook a silent threat: moisture damage to the wooden substructure. Even with durable decking, water can seep in, causing rot and expensive repairs.

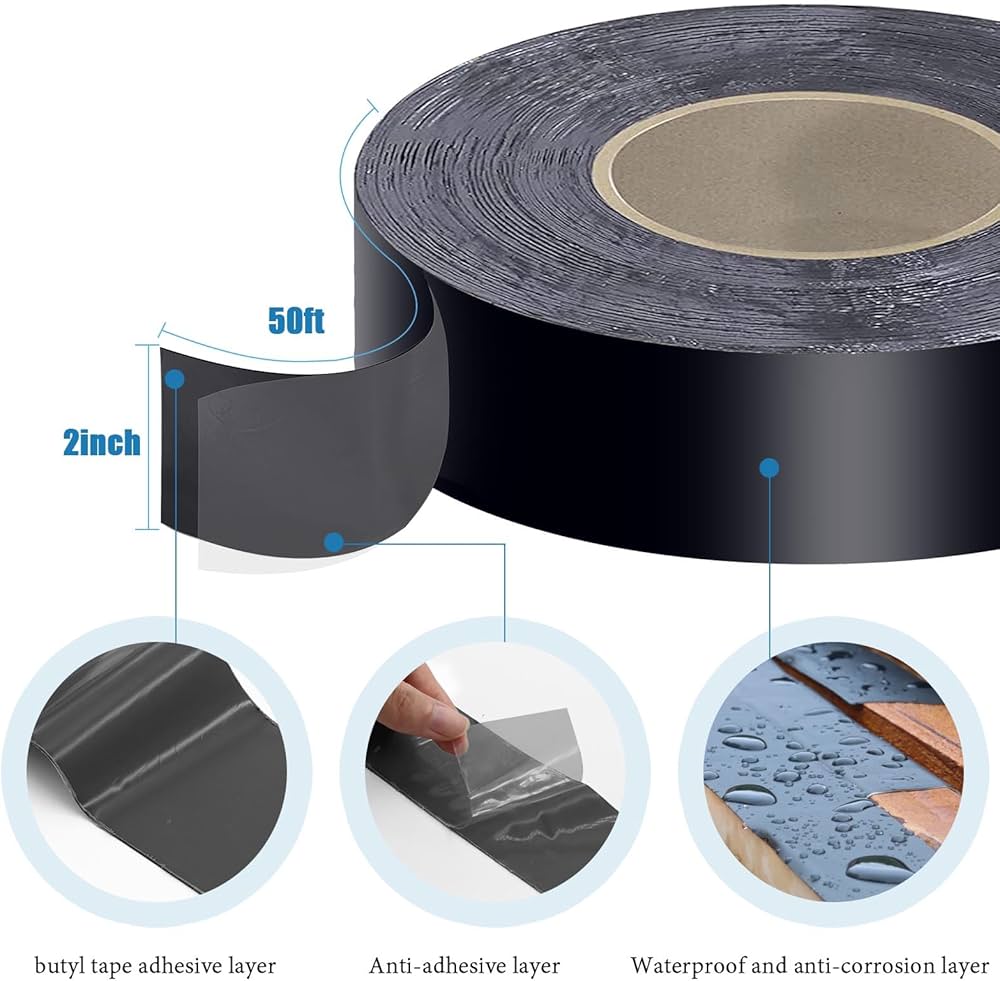

Deck joist flashing tape is a protective barrier applied to the tops of deck joists and beams. It prevents water damage and rot by sealing out moisture, especially around fasteners. High-quality butyl tape is best, as it self-seals around screws and lasts longer.

The problem isn’t always visible. This guide will cover the importance of joist tape, how to use it, and why it matters for protecting your deck’s longevity, especially when it come to water and fastener damage.

What Is Deck Joist Flashing Tape?

Imagine your deck’s wooden frame constantly battling moisture. Even treated lumber can succumb to rot over time, especially where water pools.

Deck joist flashing tape1[1] is a self-adhering membrane applied to the tops of joists and beams before installing deck boards. It creates a waterproof barrier that protects the wood from moisture, preventing rot and extending the life of the substructure.

Understanding the Purpose of Joist Tape

Joist tape isn’t just about waterproofing; it’s about isolation. It creates a critical barrier between the deck boards and the joists. This stops moisture from building up in the gap. The best tapes, especially the butyl-based ones, self-seal around screws. This prevents water from getting into the wood through these weak spots.

Types of Joist Tape

- Butyl Tape2: Known for superior adhesion, self-sealing capabilities, and long-term durability. It remains flexible in various temperatures and doesn’t ooze like asphalt tape.

- Asphalt Tape3: A cheaper alternative, but less effective. It can melt in heat, crack in cold, and has a shorter lifespan.

Is deck joist flashing tape necessary?

You might think treated lumber is enough protection. However, even treated wood can rot when water constantly gets in, especially around screws and nails.

Yes, deck joist flashing tape is necessary. Even with pressure-treated lumber, moisture can penetrate through fastener holes and cause rot. Joist tape creates a barrier, preventing water from reaching the wood and significantly extending the life of your deck’s substructure.

The Silent Threat to Deck Substructures

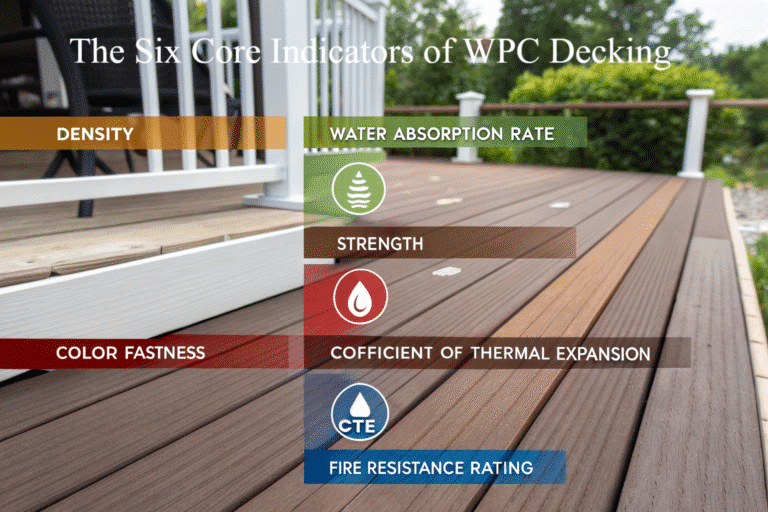

Even durable decking materials like WPC (Wood-Plastic Composite) can’t fully protect the wooden frame underneath. Pressure-treated lumber resists rot, but it’s not entirely waterproof. Water tends to gather on top of joists, particularly under the deck boards, and seeps in through fastener holes. This creates an environment where decay can thrive, even in treated wood.

Long-Term Protection

Joist tape is a proactive measure. It prevents problems before they start, saving you from costly repairs or even complete deck replacement down the line. It’s an essential element for a long-lasting deck, regardless of the decking material.

Not Just for Wood Decks

Even if you’re using WPC decking, which is waterproof, the wooden frame underneath still needs protection. Joist tape is a standard practice in the WPC industry to ensure the entire deck system lasts.

What are the benefits of Deck Joist Flashing Tape?

You may be wondering if the extra step of applying joist tape is worth it. Many builders and DIYers skip it to save time and money.

The benefits of deck joist flashing tape include preventing wood rot, extending the life of your deck’s substructure, and reducing long-term repair costs. It also protects against water damage around fastener holes and provides peace of mind knowing your deck is protected.

Preventing Wood Rot

This is the primary benefit. By blocking water, joist tape eliminates the main cause of wood rot in deck substructures.

Extending Deck Life

A healthy substructure means a longer-lasting deck. Joist tape protects the foundation of your deck, ensuring its structural integrity for years to come.

Reducing Repair Costs

Preventing damage is always cheaper than fixing it. Joist tape minimizes the risk of needing costly repairs or replacements in the future.

Specific Advantages

Here’s a table detailing the advantages

| Benefit | Description |

|---|---|

| Prevents Wood Rot | Blocks moisture, the primary cause of wood decay. |

| Extends Deck Life | Protects the substructure, ensuring the deck’s structural integrity. |

| Reduces Repair Costs | Prevents damage, minimizing the need for costly repairs or replacements. |

| Peace of Mind | Provides confidence that your deck’s substructure is protected. |

| Protects Fasteners | Many tapes self-seal around screws and nails, preventing water intrusion through these points. |

Beyond Waterproofing

Some contractors argue that tape traps moisture. But with proper installation and high-quality butyl tape, this isn’t true. The tape acts as a barrier to water coming in from above. It also allows the wood to breathe from the sides and bottom.

What is the best tape for deck joists?

Choosing the right tape can be confusing with so many options available. It’s tempting to go for the cheapest, but that can be a mistake.

The best tape for deck joists is butyl rubber tape. It offers superior adhesion, self-sealing capabilities around fasteners, and long-term durability compared to asphalt-based tapes. It also remains flexible in a wider range of temperatures.

Butyl vs. Asphalt

As mentioned earlier, butyl tape is superior to asphalt. It adheres better, seals better, lasts longer, and handles temperature changes more effectively. Asphalt tape can become messy in heat and brittle in cold.

Key Features to Look For

- Self-Sealing: The tape should seal around screws and nails, preventing water from entering.

- Adhesion Strength: It needs to stick firmly to the wood and stay in place.

- UV Resistance: Exposure to sunlight can degrade some materials, so UV resistance is important.

- Temperature Range: Choose a tape that performs well in your climate’s temperature extremes.

Why Butyl is the Industry Standard

Most professionals recommend butyl tape for its proven performance and longevity. It’s a small investment that provides significant protection.

Top Deck Joist Tape Brands to Consider

There are many brands out there. Choosing a reputable one ensures you’re getting a quality product.

Some top deck joist tape brands to consider include Trex Protect, DeckWise WiseWrap, Cofair Quick Flash Butyl Tape, and Resisto Joist Guard. These brands are known for their quality, durability, and ease of application.

Brand Overview

- Trex Protect: Specifically designed for use with Trex decking, but suitable for all decks. Known for its strong adhesion and 20-year warranty.

- DeckWise WiseWrap: Offers a butyl tape with a self-sealing membrane and a rubberized asphalt adhesive for added protection.

- Resisto Joist Guard: Provides a self-adhesive membrane made of elastomeric bitumen, which is SBS modified, and a trilaminate woven polyethylene. Easy to apply, and self-sealing.

Researching Brands

Always look for reviews and compare specifications before choosing a brand. Consider factors like warranty, material composition, and ease of installation.

It also provides customer service and support, which is reassuring.

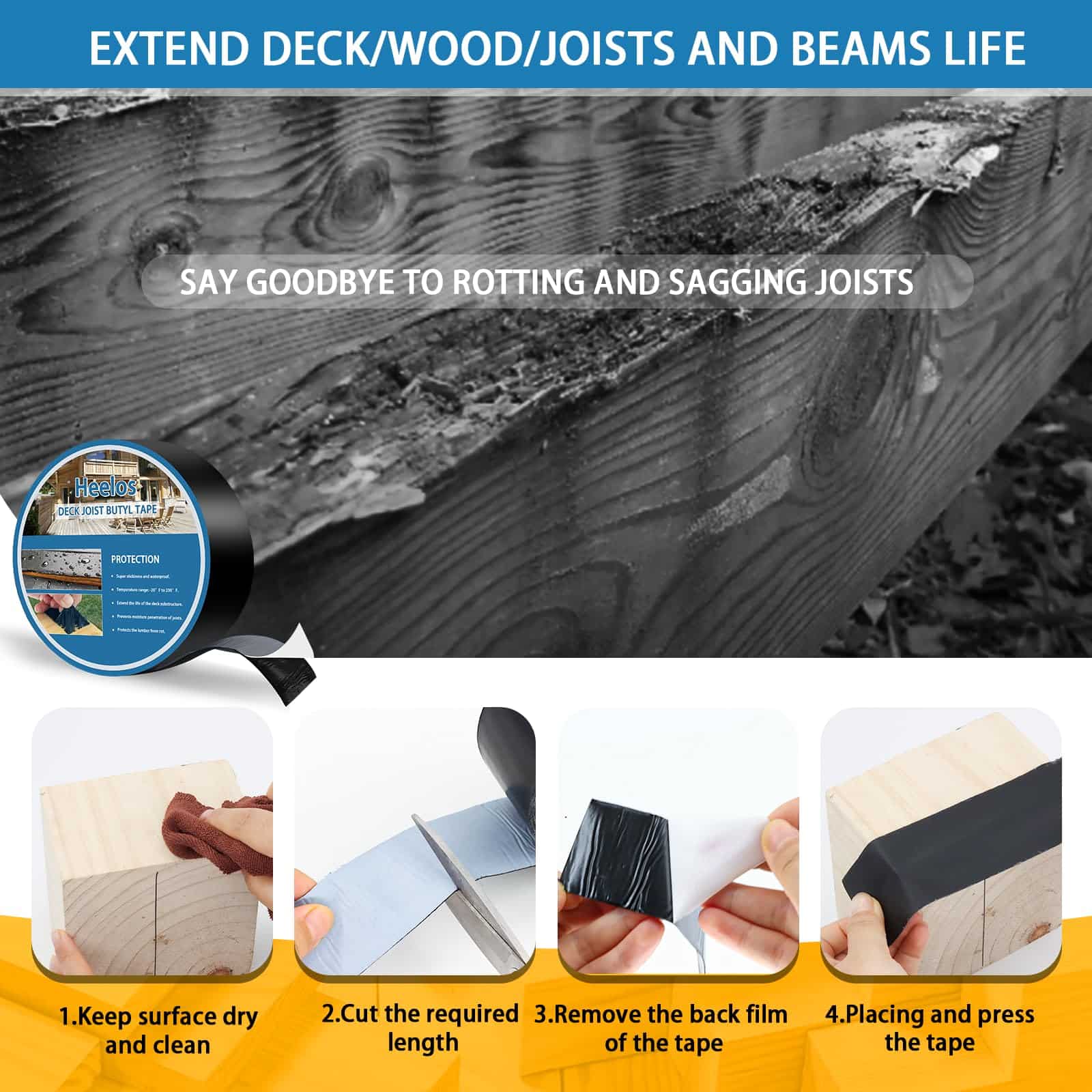

How to Install Deck Joist Tape: Step-by-Step Guide

Proper installation is crucial for the tape to work effectively. Skipping steps or doing a sloppy job can compromise its performance.

To install deck joist tape, clean the joists, apply the tape smoothly along the top, pressing firmly to ensure adhesion, and overlap seams properly. Use a roller for best results, and avoid wrinkles or bubbles.

Step-by-Step Instructions

- Clean the Joists: Ensure the joist surfaces are clean, dry, and free of debris. Sweep or brush them off.

- Apply the Tape: Start at one end of the joist, unrolling the tape and positioning it centrally along the top.

- Press Firmly: Apply firm, even pressure as you go, using your hands or, ideally, a hand roller. This ensures good adhesion and eliminates air pockets.

- Overlap Seams: When starting a new roll, overlap the previous piece.

- Fold Down Sides: If the tape is wider than the joist, fold the edges down the sides for added protection.

- Cut and Finish: Cut the tape at the end of each joist, ensuring a clean, straight edge.

Tips for Success

- Use a Roller: A hand roller or J-roller provides the most consistent pressure for optimal adhesion.

- Avoid Wrinkles: Work slowly and carefully to prevent wrinkles or bubbles, which can create gaps where water could enter.

- Dry Conditions: Apply the tape in dry conditions for the best bond.

Tools Needed

- Joist Tape

- Utility Knife or Scissors

- Hand Roller (recommended)

- Measuring Tape

FAQ

How long does deck joist tape last?

High-quality butyl deck joist tape can last for 20 years or more, often matching or exceeding the lifespan of the decking itself. Asphalt tape has a shorter lifespan, typically 5-10 years.

Can I use duct tape instead of joist tape?

No, you should not use duct tape instead of joist tape. Duct tape is not designed for long-term outdoor exposure and will not provide the necessary waterproofing or sealing properties. It will quickly degrade and fail to protect the wood.

How wide should deck joist tape be?

Deck joist tape should be wide enough to fully cover the top of the joists, with some extending down the sides. A common width is 1-5/8″ to 2″ for standard 2x joists, and wider tapes (3″ or 4″) are available for beams or doubled-up joists.

Common Mistakes to Avoid When Using Deck Joist Tape

Even with the best intentions, mistakes can happen. Knowing what to avoid can save you headaches later.

Common mistakes when using deck joist tape include applying it to dirty or wet joists, not using enough pressure for proper adhesion, not overlapping seams correctly, and creating wrinkles or bubbles. Choosing the wrong type of tape (e.g., asphalt instead of butyl) is also a mistake.

Specific Mistakes and Solutions

| Mistake | Solution |

|---|---|

| Applying to dirty/wet joists | Clean and dry joists thoroughly before application. |

| Insufficient pressure | Use a hand roller for firm, even pressure. |

| Incorrect overlapping | Overlap seams. |

| Wrinkles and bubbles | Apply slowly and carefully, smoothing out any imperfections as you go. |

| Choosing the wrong tape (e.g., asphalt) | Opt for butyl rubber tape for superior performance and longevity. |

| Skipping joist tape altogether | Always use joist tape, even with WPC decking, to protect the wooden substructure. |

The Importance of Proper Installation

Proper installation is just as important as choosing the right tape. Take your time, follow the instructions, and don’t cut corners.

Conclusion

Deck joist tape is a small investment that provides huge benefits. It’s a simple step that significantly extends your deck’s life. Protecting the substructure from moisture is crucial for avoiding costly repairs.

Source

- Explore this link to understand the benefits and applications of deck joist flashing tape for your deck’s longevity. ↩

- Learn why butyl tape is preferred for deck joists and how it can enhance your deck’s durability. ↩

- Discover the limitations of asphalt tape and why it may not be the best choice for your decking project. ↩

6 thoughts on “Deck Joist Tape: Protect Your Deck’s Substructure and Prevent Costly Repairs”

Bigbet1 is growing on me. The interface is clean and there are lots of ways to win. Giving it a thumbs up! Visit bigbet1

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

UG777Casino’s got some seriously cool games going on! Been playing there for ages and they always keep things exciting. Definitely worth checking out if you’re looking for a fun time! Click here: ug777casino

Your article helped me a lot, is there any more related content? Thanks!

Comments are closed.