How to Comply with Deck Building Codes: A Guide to Safe and Legal Outdoor Spaces?

Problem: Building a deck seems simple, but failing to follow building codes can lead to serious safety hazards and costly fines.

Agitate: Imagine your beautiful new deck collapsing because you overlooked a critical structural requirement.

Solve: This guide breaks down deck building codes, ensuring your project is safe, legal, and built to last.

Deck building codes are essential for safety and structural integrity, preventing collapses and injuries. They cover aspects like foundation, framing, railings, stairs, material requirements, and load capacity. Compliance ensures your deck meets local regulations, avoiding fines and legal issues.

However, navigating the complex world of deck building codes is no easy. Let’s simplify these critical regulations, section by section.

Why Deck Building Codes Matter?

Problem: Ignoring building codes seems like a shortcut, but it’s a dangerous gamble. Why take unnecessary risks?

Agitate: Imagine your deck collapsing during a family gathering, causing serious injuries. The consequences could be devastating.

Solve: Deck building codes are designed to ensure your deck is structurally sound and safe for everyone.

Deck building codes prioritize safety, preventing accidents and injuries. They ensure structural stability, protecting your investment and ensuring your deck can handle its intended use. Compliance also prevents legal issues, fines, and potential liability.

Building codes aren’t just suggestions; they’re laws designed to protect you and your community. Think of them as a recipe for a safe and successful deck project. They provide a minimum standard for construction, addressing potential hazards like structural failure, fire spread, and electrical mishaps. Adhering to these codes means your deck will withstand the test of time and the elements, providing a secure and enjoyable outdoor space for years to come.

Benefits of Compliance

| Benefit | Description |

|---|---|

| Safety | Prevents accidents, injuries, and potential fatalities. |

| Structural Integrity | Ensures the deck is stable, durable, and can support intended loads. |

| Legal Protection | Avoids fines, legal liabilities, and potential lawsuits. |

| Property Value | A code-compliant deck adds value to your property and assures potential buyers of its quality. |

| Insurance Coverage | Ensures your deck is covered by insurance in case of damage or accidents. |

| Peace of Mind | Knowing your deck is built to the highest standards provides peace of mind. |

Key Deck Building Codes You Should Know

Problem: Deck codes are a maze of regulations. It’s hard to know where to begin.

Agitate: Imagine making a critical mistake that compromises your deck’s structural integrity1.

Solve: We’ll cover the key codes, from foundation to railings, ensuring you’re well-informed.

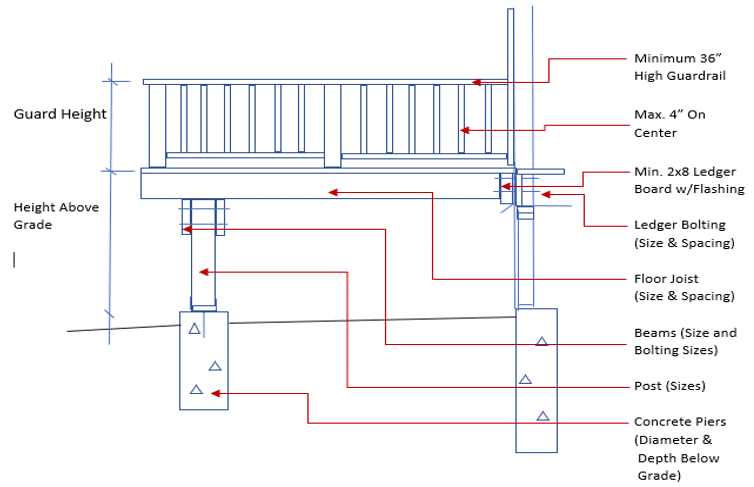

Key deck codes cover footings2, ledger board attachment, joist spacing, load capacity3, guardrails4, stairs, and materials. Local codes may have additional requirements or variations from the International Residential Code (IRC).

Understanding the key codes is paramount. These regulations are not arbitrary; they are based on engineering principles and years of experience to ensure deck safety. They cover every aspect of the deck, from the foundation that supports it to the railings that protect its users. Familiarizing yourself with these codes is the first step towards building a safe and compliant deck.

Core Code Areas

| Code Area | Description |

|---|---|

| Founding | Specifies requirements for footings, ensuring adequate support and stability. |

| Structural Support | Covers joists, beams, framing, and posts, ensuring the deck can handle intended loads. |

| Guardrails | Mandates railings for decks above a certain height, specifying height, spacing, and strength requirements. |

| Stairs | Defines requirements for stair width, riser height, tread depth, and handrails. |

| Ledger Board | Specifies how the deck attaches to the house, a critical connection point. |

| Materials | Dictates acceptable materials for decking and structural components, often referencing specific standards like ASTM D7032 for WPC. |

| Load Capacity | Specifies the minimum weight the deck must be able to support, usually 40 pounds per square foot (psf). |

| Permits | Most jurisdictions require a permit, ensuring plans are reviewd and construction is inspected. |

Founding

Problem: Footings might seem like a minor detail, but they’re the foundation of your deck’s stability.

Agitate: Imagine your deck sinking or shifting because the footings were inadequate.

Solve: Properly sized and installed footings are crucial for preventing settling and ensuring long-term stability.

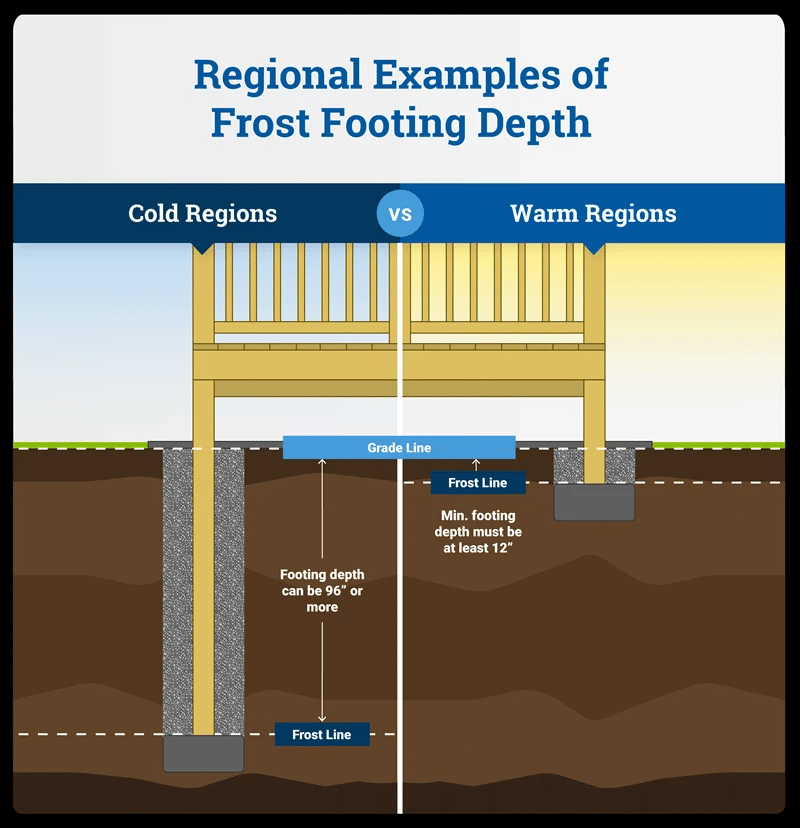

Footings must extend below the frost line and be appropriately sized for the load and soil conditions. Local codes specify the required depth and dimensions, ensuring a stable foundation for your deck.

Footings are the unsung heroes of deck construction. They distribute the deck’s weight to the ground, preventing it from sinking or shifting. The depth and size of the footings are critical and depend on several factors, including the local frost line (the depth to which the ground freezes in winter), the soil type, and the anticipated load on the deck. Local building codes always specify the minimum footing requirements for your area.

Deep Dive:

| Factor | Description |

|---|---|

| Frost Line | Footings must extend below the frost line to prevent heaving caused by freezing and thawing soil. |

| Soil Type | Different soil types have different bearing capacities. Clay, for example, requires larger footings than sand. |

| Load Calculation | The size of the footing is determined by the total load it must support, including the deck’s weight and live load. |

| Local Codes | Always refer to your local building codes for specific footing requirements. |

More related information, pls visit A Complete Guide to Deck Footings5.

Structural support: joist, beam, framing, post

Problem: The structure beneath your deck boards is complex. Understanding the roles of joists, beams, and posts is critical.

Agitate: Imagine your deck collapsing because a joist or beam failed.

Solve: We’ll clarify the function of each structural component and the codes that govern them.

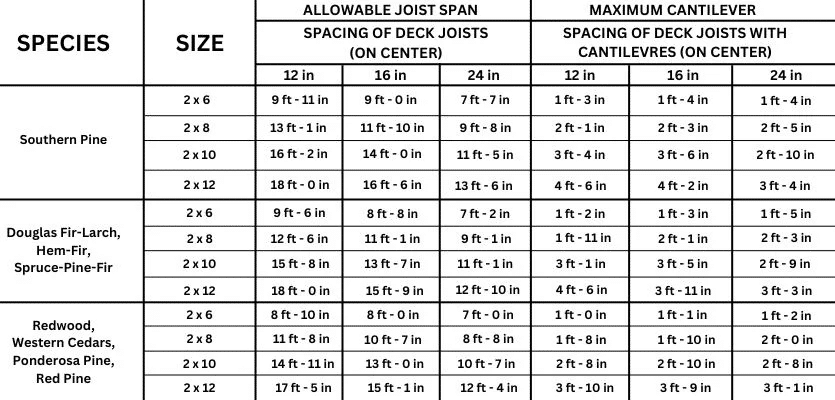

Joists, beams, framing, and posts form the deck’s structural skeleton. Codes specify spacing, size, and material requirements to ensure the deck can safely support the intended load.

The structural support system is the backbone of your deck. Joists are the horizontal members that directly support the decking boards. Beams are larger members that support the joists, and posts are the vertical members that transfer the load to the footings. The spacing and size of these components are crucial for ensuring the deck can handle the intended load without excessive deflection or failure.

Structural Support Breakdown:

| Component | Function | Code Considerations |

|---|---|---|

| Joists | Directly support the decking boards. | Spacing is critical and often smaller for WPC than wood. Always follow the WPC manufacturer’s specifications. |

| Beams | Support the joists, spanning longer distances. | Size and spacing depend on the load and span. |

| Posts | Transfer the load from the beams to the footings. | Size and spacing depend on the load and height of the deck. |

| Framing | Include all structural components. | Must be properly connected and braced to resist lateral loads and ensure overall stability. |

Guardrails and Railings Codes

Problem: Railings are more than just decorative; they’re a vital safety feature.

Agitate: Imagine someone falling from your deck because the railings were inadequate or missing.

Solve: We’ll explain the code requirements for guardrail height, spacing, and strength.

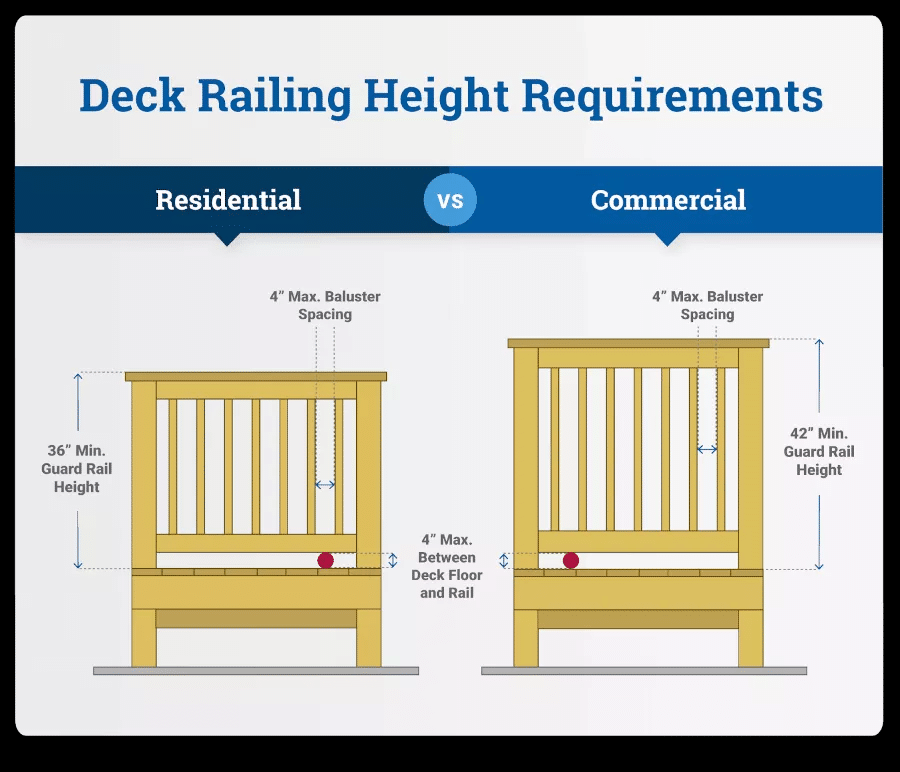

Guardrails are required for decks over 30 inches above grade6. Codes specify minimum height (usually 36 inches), maximum baluster spacing (preventing a 4-inch sphere from passing), and strength requirements to withstand force.

Guardrails are critical for preventing falls, especially on elevated decks. The codes governing guardrails are stringent and focus on three key aspects: height, spacing, and strength. The height requirement ensures that the railing is tall enough to prevent someone from accidentally falling over it. The spacing requirement, often referred to as the "4-inch sphere rule," prevents small children from slipping through the balusters. The strength requirement ensures the railing can withstand a certain amount of force without breaking.

Guardrail Code Details:

| Requirement | Description |

|---|---|

| Height | Typically a minimum of 36 inches, but local codes may require 42 inches. |

| Spacing | Balusters must be spaced close enough to prevent a 4-inch sphere from passing through. |

| Strength | Must withstand a specified horizontal and vertical load, often a 200-pound concentrated load. |

| Industry Experience | Railings must be at least 42 inches, and no more than 5 inches of space should be between the railings. |

Wanna learn more details, pls read What is the Right Deck Railing Height?7

Deck Stair codes and safety

Problem: Deck stairs are a common source of accidents. Improperly built stairs are a major hazard.

Agitate: Imagine someone tripping and falling on your poorly constructed deck stairs.

Solve: We’ll cover the code requirements for stair width, riser height, tread depth, and handrails.

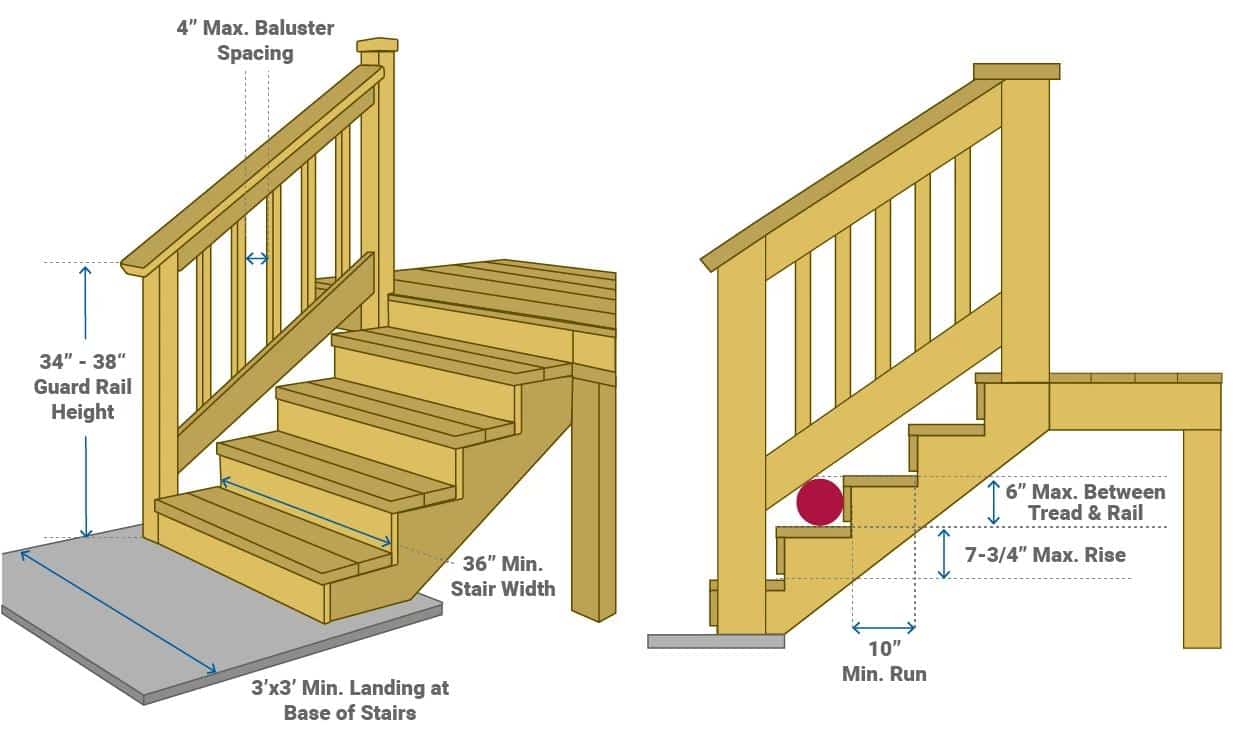

Deck stair codes mandate minimum width (usually 36 inches), consistent riser height and tread depth (with minimal variation), and handrails for stairs with more than a few risers, ensuring safe and comfortable use.

Stair codes are meticulously designed to ensure safety and ease of use. Consistency is key. Variations in riser height (the vertical distance between steps) and tread depth (the horizontal distance of each step) can create tripping hazards. Codes typically limit the variation to a maximum of 3/8 inch between steps. Handrails are required for stairs with more than a few risers, providing support and preventing falls.

Stair Code Specifics:

| Requirement | Description |

|---|---|

| Width | Usually a minimum of 36 inches. |

| Riser Height | Typically between 7 and 7 ¾ inches. |

| Tread Depth | Typically a minimum of 10 inches. |

| Variation | Minimal variation allowed between riser heights and tread depths (usually no more than 3/8 inch). |

| Handrails | Required for stairs with more than a few risers, with specific requirements for height, graspability, and run. |

WPC stair treads, like decking, often have specific installation instructions. Pay meticulous attention to these details.

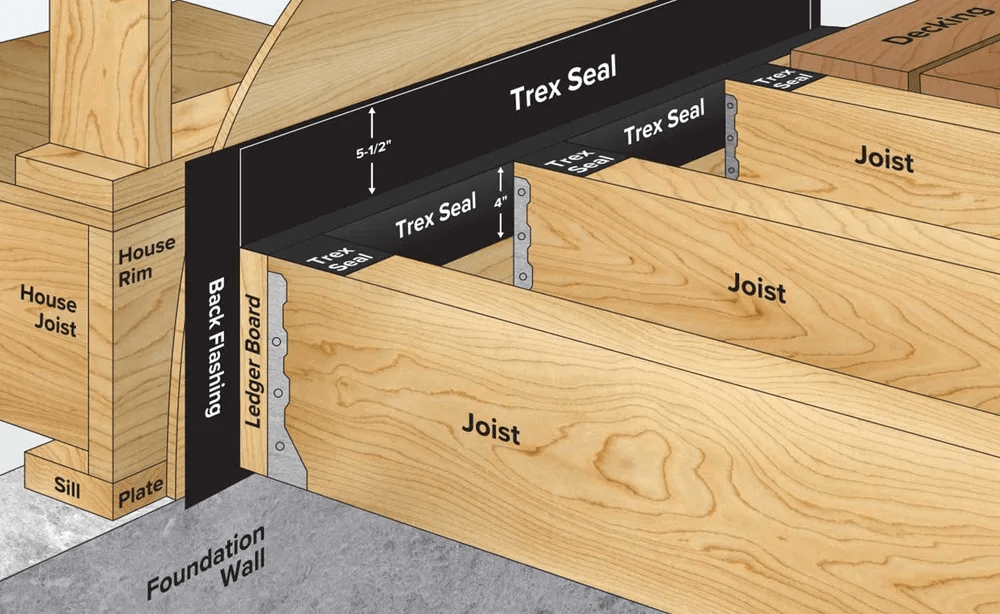

Deck ledger board codes

Problem: The ledger board connection is a critical point of failure for many decks.

Agitate: Imagine your entire deck collapsing because the ledger board wasn’t properly attached.

Solve: We’ll explain the crucial requirements for bolting the ledger board to the house and using proper flashing8.

The ledger board must be bolted (not nailed) to the house’s structural framing9, and proper flashing is essential to prevent water intrusion and rot, which can lead to catastrophic failure. Using lag screws or bolts is highly recommended.

The ledger board is the structural member that attaches the deck to the house. This connection is critical, and it’s a common point of failure for decks that are not built to code. The ledger board must be securely bolted to the house’s rim joist or another structural member, not simply nailed. Nails can pull out over time, leading to deck collapse. Proper flashing is also essential to prevent water from getting behind the ledger board and causing rot, which can weaken the connection and the house’s structure.

Ledger Board Best Practices:

| Element | Description |

|---|---|

| Attachment | Must be bolted to the house’s structural framing using lag screws or through-bolts, not nails. |

| Flashing | Proper flashing is essential to prevent water intrusion and rot. |

| Spacing | Bolt spacing is specified by code and depends on the load and the size of the ledger board. |

| Material | The ledger board must be made of pressure-treated lumber or another approved material that is resistant to decay and insects. |

With the ledger board connection, you should use lag screws or bolts.

Material Requirement

Problem: Choosing the right materials is essential for both durability and code compliance.

Agitate: Imagine using substandard materials that rot or fail prematurely.

Solve: We’ll outline the code requirements for wood and WPC decking materials.

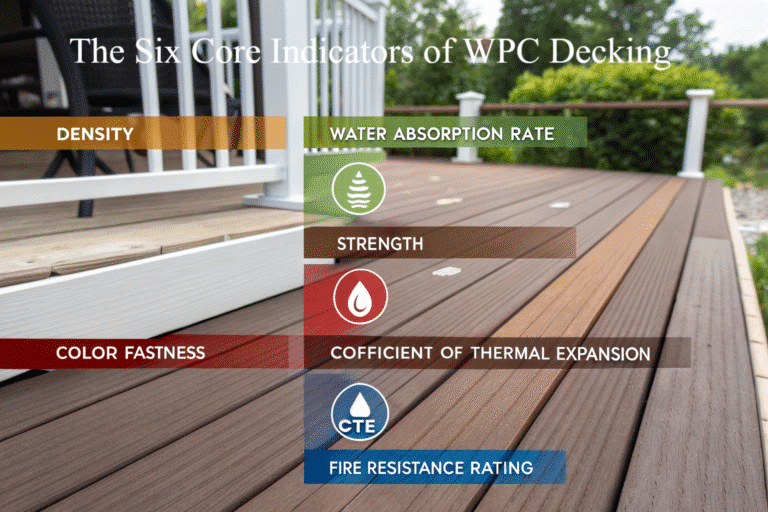

Wood used for structural components must be pressure-treated or naturally decay-resistant10. WPC decking must meet specific standards, often referenced by ASTM D703211. Look for an ICC-ESR12 (Evaluation Service Report) for WPC to ensure code compliance.

The materials you choose for your deck must meet specific requirements to ensure durability and safety. For wood, this typically means using pressure-treated lumber that is resistant to decay and insect damage. For WPC decking, it’s crucial to choose products that meet recognized standards, such as ASTM D7032. An ICC-ESR (Evaluation Service Report) provides independent verification that a WPC product has been tested and meets the relevant code requirements.

Material Guidelines:

| Material | Requirement |

|---|---|

| Wood | Must be pressure-treated or naturally decay-resistant (like cedar or redwood) for structural components. |

| WPC | Must meet specific standards, often referenced by ASTM D7032. Look for an ICC-ESR for verification. |

An ICC-ESR provides independent verification that a WPC product has been rigorously tested and meets the relevant code requirements. Don’t rely solely on the manufacturer’s claims.

Load Capacity

Problem: Overloading a deck can lead to catastrophic failure.

Agitate: Imagine your deck collapsing under the weight of too many people or heavy furniture.

Solve: We’ll explain the code requirements for deck load capacity.

The IRC generally requires a minimum live load capacity of 40 pounds per square foot (psf) and a dead load of 10 psf. However, local codes may specify higher requirements, especially in areas with heavy snow loads.

Load capacity refers to the amount of weight a deck can safely support. Codes specify both a live load (the weight of people, furniture, and other movable objects) and a dead load (the weight of the deck itself). The IRC generally requires a minimum live load capacity of 40 psf(Some areas now require 60 psf), but local codes may require higher capacities, especially in areas with heavy snow loads. It’s crucial to design your deck to meet or exceed the required load capacity for your area.

Load Capacity Factors:

| Factor | Description |

|---|---|

| Live Load | The weight of people, furniture, and other movable objects. |

| Dead Load | The weight of the deck itself, including decking, framing, and railings. |

| Local Codes | May specify higher load requirements than the IRC, particularly in areas with heavy snow or high winds. |

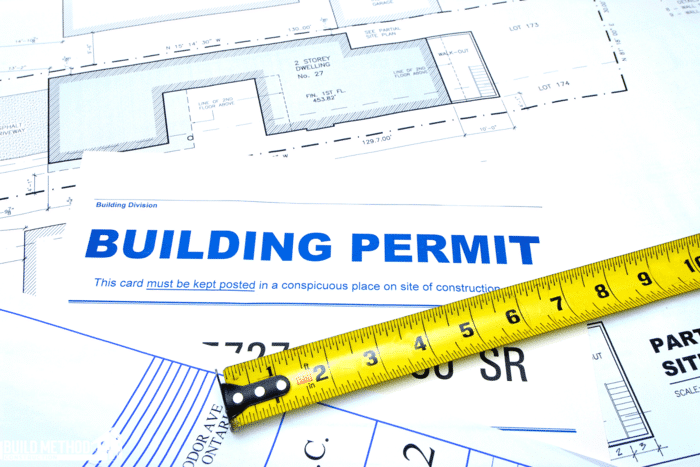

Permits

Problem: Skipping the permit process might seem tempting, but it’s a risky move.

Agitate: Imagine facing fines, legal issues, or having to tear down your deck because you didn’t get a permit.

Solve: We’ll explain why permits are essential and what the process typically involves.

Almost all deck projects require a building permit, involving submitting plans and undergoing inspections to ensure code compliance. This process protects you and ensures your deck is built safely and legally.

A building permit is not just a bureaucratic formality; it’s a crucial step in ensuring your deck is built safely and legally. The permit process typically involves submitting detailed plans of your deck to the local building department for review. The plans are checked to ensure they meet all applicable codes. During construction, inspections are conducted at various stages to verify that the work is being done according to the approved plans.

Permit Process Steps:

| Step | Description |

|---|---|

| Plan Submission | Submit detailed plans of your deck to the local building department. |

| Plan Review | The building department reviews your plans to ensure they meet all applicable codes. |

| Permit Issuance | Once your plans are approved, you’ll receive a building permit. |

| Inspections | Inspections are conducted at various stages of construction to verify code compliance. |

| Final Approval | After the final inspection, you’ll receive final approval, indicating your deck is complete and code-compliant. |

| What to Submit | A completed application, 2 Sets of Construction plans, Site Plans, Contractors need copy of their license, Payment of the building permit fee. |

Step-by-step Guide to Ensure Compliance in Your Projects

Problem: Ensuring code compliance throughout the entire deck building process can be overwhelming.

Agitate: Imagine overlooking a critical detail that leads to non-compliance and costly rework.

Solve: We’ll provide a step-by-step guide to help you navigate the process, from planning to final inspection.

Start with local code research, obtain necessary permits, create detailed plans, follow manufacturer instructions (especially for WPC), schedule inspections, and maintain thorough documentation for a smooth, code-compliant deck project.

Building a code-compliant deck is a process that requires careful planning and execution. Start by researching your local building codes, as they may have specific requirements or amendments to the IRC. Obtain the necessary permits before starting any work. Create detailed plans that clearly show all aspects of the deck, including dimensions, materials, and structural details. Follow the manufacturer’s installation instructions, particularly for WPC decking, as it often has specific requirements for joist spacing and fastening.

Step-by-Step Compliance Checklist:

- Research Local Codes: Contact your local building department to obtain the most up-to-date codes and any local amendments.

- Obtain Permits: Apply for and obtain all necessary building permits before starting construction.

- Create Detailed Plans: Develop comprehensive plans that include all dimensions, materials, structural details, and connections.

- Choose Code-Compliant Materials: Select materials that meet the specified standards, including pressure-treated lumber or WPC with an ICC-ESR report.

- Follow Manufacturer Instructions: Adhere strictly to the manufacturer’s installation guidelines, especially for WPC decking.

- Proper Construction Techniques: Ensure all work is done according to best practices and code requirements, paying close attention to structural connections and flashing.

- Schedule Inspections: Schedule all required inspections at the appropriate stages of construction.

- Address Inspector Feedback: Promptly address any issues or concerns raised by the building inspector.

- Maintain Documentation: Keep detailed records of all plans, permits, inspections, and material specifications.

- Final Inspection and Approval: Obtain final approval from the building department after the final inspection.

Common Mistakes to Avoid When Building a Deck

Problem: Even experienced builders can make mistakes that lead to code violations.

Agitate: Imagine having to redo work or face fines because of a simple oversight.

Solve: We’ll highlight common mistakes to avoid, ensuring your project stays on track.

Common mistakes include exceeding WPC joist spacing limits, improper ledger board attachment, inadequate footings, incorrect railing height or spacing, inconsistent stair risers and treads, and neglecting to obtain necessary permits.

Even experienced builders can make mistakes that lead to code violations. Avoiding these common pitfalls can save you time, money, and potential headaches. One of the most frequent mistakes with WPC decking is exceeding the manufacturer’s specified joist spacing. This can lead to sagging, excessive bounce, and even structural failure. Improper ledger board attachment is another serious error, often resulting from using nails instead of bolts or neglecting proper flashing.

Top Mistakes to Avoid:

| Mistake | Consequence | Prevention |

|---|---|---|

| Exceeding WPC Joist Spacing | Sagging, excessive bounce, structural failure. | Always follow the manufacturer’s specified joist spacing for your chosen WPC product. |

| Improper Ledger Board Attachment | Deck collapse, water damage to the house. | Bolt the ledger board to the house’s structural framing and use proper flashing. |

| Inadequate Footings | Deck settling, shifting, or instability. | Ensure footings are below the frost line and appropriately sized for the load and soil conditions. |

| Incorrect Railing Height/Spacing | Increased risk of falls. | Follow code requirements for minimum railing height and maximum baluster spacing. |

| Inconsistent Stair Risers/Treads | Tripping hazards. | Maintain consistent riser height and tread depth, with minimal variation. |

| Neglecting Permits | Fines, legal issues, potential tear-down of the deck. | Obtain all necessary permits before starting construction. |

Never exceed the manufacturer’s specified joist spacing for your chosen WPC product. This is, in my experience, the most frequent and serious mistake made with WPC decking installations. It results in sagging, excessive bounce, and potential structural failure. The span requirements are located in the manufactures guidelines.

Resources for Deck Building Professionals

Problem: Staying up-to-date on building codes and best practices can be challenging.

Agitate: Imagine falling behind on code changes or industry advancements.

Solve: We’ll provide valuable resources for deck building professionals.

Resources include the International Code Council (ICC)13, local building departments, WPC manufacturer websites and documentation (look for ICC-ESR reports), and industry associations like the North American Deck and Railing Association (NADRA)14.

The world of building codes and construction techniques is constantly evolving. Staying informed is crucial for professionals in the deck building industry. The International Code Council (ICC) is the primary source for the International Residential Code (IRC) and other model codes. Local building departments are the ultimate authority on local codes and amendments. WPC manufacturer websites and product documentation, particularly ICC-ESR reports, provide valuable information on specific product requirements and installation guidelines.

Key Resources:

- International Code Council (ICC): iccsafe.org

- Local Building Departments: Contact your city or county government.

- WPC Manufacturer Websites: Look for product documentation, installation guides, and ICC-ESR reports.

- North American Deck and Railing Association (NADRA): nadra.org

- Deck Expo: A good place to learn about new industry information.

Conclusion

Building a deck that complies with codes is not only a legal requirement but also a fundamental responsibility for safety and durability. By following this guide and being diligent, you can build a stunning outdoor space.

FAQ

What is the largest deck size allowed without a permit?

This varies significantly by local jurisdiction. Some areas allow very small decks (e.g., under 200 square feet and less than 30 inches above grade) without a permit, while others require permits for all decks. Always check with your local building department.

What are the key requirements for building a deck?

Key requirements include proper footings, structurally sound framing (joists, beams, posts), secure ledger board attachment, code-compliant guardrails and stairs, appropriate materials, and adherence to load capacity limits.

What is the code for deck post spacing and joist spacing?

Post spacing depends on the load and beam size. Joist spacing is often dictated by the decking material; WPC frequently requires closer spacing than wood. Always consult the manufacturer’s specifications and local codes.

What Happens If I Don’t Follow Deck Building Codes?

Consequences can include fines, legal liabilities, stop-work orders, required demolition and reconstruction, and potential safety hazards leading to injuries.

How do local building codes differ from the IRC for deck construction?

Local codes can amend the IRC, adding stricter requirements or adapting to specific regional conditions like seismic activity, high winds, or heavy snow loads. Always consult your local building department.

How can I quickly check my local deck building codes?

Contact your local building department (city or county). They are the authoritative source for local codes and can provide information and resources.

How can I stay updated on building code changes?

Subscribe to publications from the International Code Council (ICC), attend industry events, and regularly check your local building department’s website for updates.

How can I document compliance in a project for auditing purposes?

Keep detailed records of all plans, permits, inspections, material specifications (including ICC-ESR reports for WPC), and any communication with the building department.

-

structural integrity: Exploring structural integrity helps you grasp the importance of building a safe deck that can withstand various loads and conditions.

Learn More About Structural Integrity ↩ -

Footings: Understanding the requirements for footings is essential for ensuring your deck’s stability and safety.

Explore Footing Guidelines ↩ -

Load capacity: Knowing how load capacity is calculated helps in designing a safe deck.

Discover Load Standards ↩ -

Guardrails: Guardrails are crucial for deck safety. Learn about the regulations to ensure your deck is compliant and safe for use.

View Guardrail Regulations ↩ -

A Complete Guide to Deck Footings: How to Build Deck Footings? A Complete Guide to Deck Footings.

Read Full Guide ↩ -

Guardrails are required for decks over 30 inches above grade: Learn about essential safety regulations that protect against falls and ensure your deck meets legal standards.

Check Height Requirements ↩ -

What is the Right Deck Railing Height?: What is the Right Deck Railing Height?

See Railing Standards ↩ -

Proper flashing: Deck Joist Tape: Protect Your Deck’s Substructure and Prevent Costly Repairs.

Learn Flashing Techniques ↩ -

Ledger board must be bolted (not nailed) to the house’s structural framing: Discover the critical connection that supports your deck and prevents catastrophic failures. This knowledge is vital for safe construction.

Understand Bolting Methods ↩ -

pressure-treated or naturally decay-resistant: Explore the advantages of using pressure-treated or naturally decay-resistant wood to ensure your deck’s longevity and safety.

Compare Material Options ↩ -

ASTM D7032: Learn about ASTM D7032 standards to ensure your WPC decking meets safety and performance requirements.

Review ASTM Standards ↩ -

ICC-ESR: Discover the significance of ICC-ESR reports in verifying the quality and compliance of your decking materials.

Access ICC ESR Resources ↩ -

International Code Council (ICC): The ICC offers essential resources and updates on building codes that every deck builder should know.

Visit ICC Website ↩ -

North American Deck and Railing Association (NADRA): NADRA provides industry insights, networking opportunities, and resources that can enhance your deck building knowledge.

Explore NADRA Resources ↩

3 thoughts on “How to Comply with Deck Building Codes: A Guide to Safe and Legal Outdoor Spaces?”

5jlcomlogin makes accessing my account super easy. No hassle, straight to the action! Register is simple as well! Check it out: 5jlcomlogin

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.info/register-person?ref=IXBIAFVY

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Comments are closed.