Master All WPC Fence Accessories in 5 Minutes

Are you considering installing a WPC fence but feeling overwhelmed by the variety of accessories? Don’t worry! As an industry expert with twenty years of experience, let me guide you through the common types, functions, and selection tips for WPC fence accessories in just 5 minutes, helping you easily create an outdoor boundary that is both beautiful and durable.

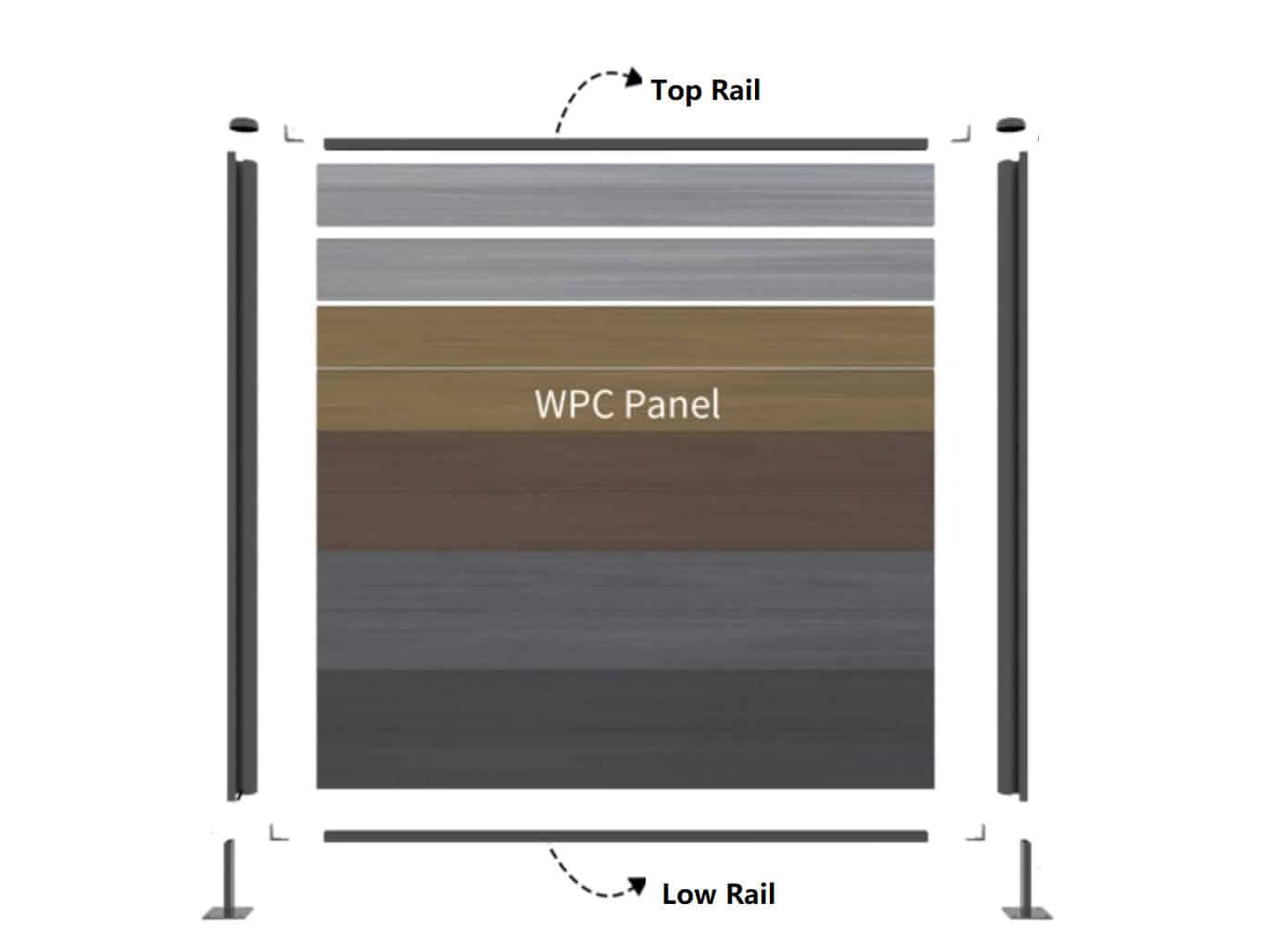

WPC Fence System Components

The core components of a WPC fence system include WPC fence panels, WPC fence post bases, WPC fence posts, WPC fence rails, WPC fence angle brackets, and various connecting accessories. These elements not only provide structural support but also determine the overall appearance and functionality of the fence. Unlike traditional wooden fences, WPC fence accessories are specially designed to resist rot, pests, and harsh weather, significantly extending their lifespan while reducing maintenance needs.

Practical Tips and Advice for You

-

Measure Before Buying: Accurately measure your yard’s perimeter and allow for extra materials for gates, corners, and height variations.

-

Use Accessories from the Same Brand: Whenever possible, use all WPC fence accessories from the same manufacturer to ensure a perfect fit and consistent quality standards.

-

Climate Considerations: In areas with extreme climates, choose WPC fence accessories specifically designed for your local weather conditions.

WPC Fence Post Base: The First Step to a Stable Installation

The performance of a WPC fence largely depends on the quality and installation method of its post base system. The core function of the post base is to firmly anchor the post onto specific structures like concrete or composite decking. It provides support and stability for your fence, resisting forces from wind, impacts, and the fence’s own weight, ensuring the post remains vertical and stable.

Comparison of WPC Fence Post Bases Made from Different Materials

Common post base materials include galvanized steel, stainless steel, and aluminum alloy. Here are their differences, allowing you to choose based on your project’s specific needs.

| Characteristic | Galvanized Steel | Stainless Steel | Aluminum Alloy |

|---|---|---|---|

| Corrosion Resistance | Good Relies on a surface zinc layer for rust protection. If the galvanized layer is damaged or depleted, the base material (carbon steel) will begin to rust. |

Excellent Contains elements like chromium, forming a dense passive film with very strong resistance to rust and corrosion, especially suitable for humid, salt-spray, or acidic environments. |

Very Good Naturally forms a dense protective aluminum oxide film on the surface, offering good weather resistance and corrosion resistance; less prone to rusting. |

| Strength & Durability | High Steel itself possesses high mechanical strength and load-bearing capacity; structurally robust. |

Very High Typically stronger than regular carbon steel and aluminum alloys; very durable with good impact resistance. |

Medium Strength depends on the specific alloy grade, generally sufficient for fence support needs, but typically lower than steel. |

| Cost | Lower | High | Medium |

| Weight | Heavy | Heavy | Light (approx. 1/3 the weight of steel) |

| Maintenance Needs | Low | Very Low | Very Low |

WPC Fence Post: The Backbone Support of the System

The WPC fence post is the core support element of the entire fence structure; pay special attention to its quality and installation method. The post bears the full weight of the WPC fence panels while resisting wind and other external pressures.

Modern WPC fence posts are typically made of WPC or aluminum alloy. WPC posts match the material of the WPC fence panels, achieving a unified and coordinated appearance. Aluminum alloy posts offer high strength, excellent weather resistance, and are lightweight. They are often chosen for higher strength requirements or specific design styles, and their surface can be coated in various colors.

The standard length of fence panels determines the post spacing, commonly between 6ft and 8ft. For coastal areas and other regions with high winds, it is recommended to keep the spacing around 6ft to avoid the risk of the fence being blown over. The method for calculating the number of posts is as follows:

• Straight sections: Number of posts = (Total fence length / Standard spacing) + 1 (starting post)

• Corners: Each corner requires one post.

• On either side of a WPC fence gate: Two reinforced posts (gate posts) are needed. Gate posts are usually thicker or have stronger internal reinforcement than standard posts.

WPC Fence Post Installation

• Step 1: Ensure the post groove faces the direction of the fence panel installation, then accurately insert the post into the already installed post base.

• Step 2: Use a level or plumb bob to check the verticality of the post, ensuring it is perfectly upright.

• Step 3: Secure the post to the post base using screws from the side.

Practical Advice: Do not install any heavy items or fence components onto the post until the concrete is fully cured (typically requires 24-48 hours) to ensure the foundation reaches maximum strength.

WPC Fence Rail: Key for Connection and Support

The WPC fence rail plays a crucial role in the fence structure by connecting posts and supporting the fence panels. Quality rails not only provide adequate structural support but also prevent panels from bending or deforming over time. For most WPC fence systems, rails are typically made of aluminum alloy, combining lightweight properties with high strength.

The design and number of rails directly impact the overall strength of the fence. Standard WPC fence designs usually include at least two rails per fence section (top rail and low rail). For fences taller than 1.5 meters (approx. 5 feet), it is recommended that you add a mid rail to prevent panel deformation, thereby enhancing overall rigidity and load-bearing capacity.

WPC Fence Rail Selection and Installation Advice

-

Material Choice: Aluminum alloy rails offer the best strength-to-weight ratio and corrosion resistance.

-

Surface Finish: Ensure rails have an appropriate coating that coordinates with the color of the posts and panels.

-

Connection Method: Prefer hidden/concealed fasteners for a cleaner aesthetic.

-

Support Span: Follow the manufacturer’s recommended maximum support span, typically not exceeding 2 meters (approx. 6.5 feet).

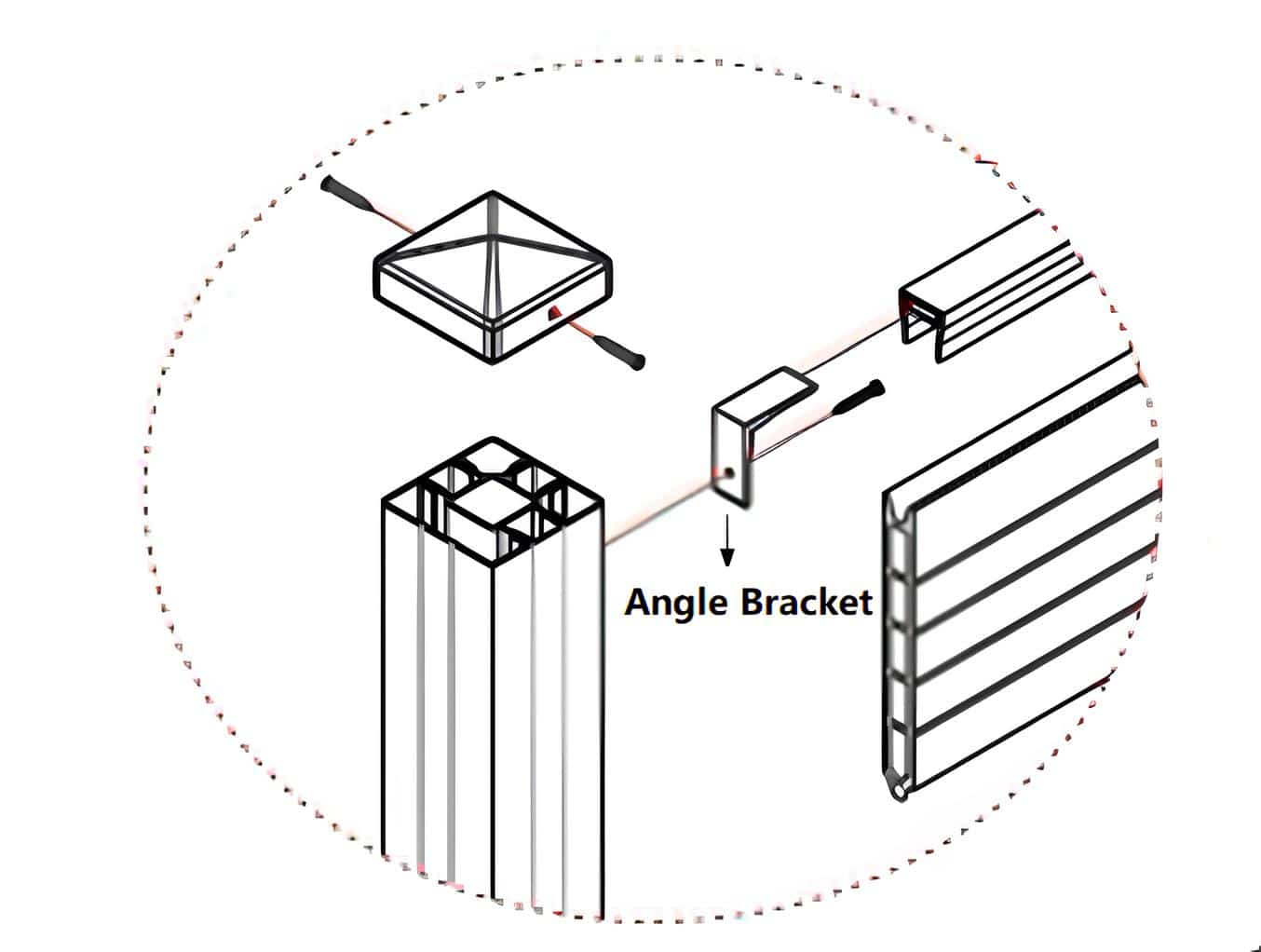

WPC Fence Angle Bracket

The WPC fence angle bracket is the hardware used to connect rails to posts. It is typically made of metal materials like galvanized steel, stainless steel, or aluminum alloy to ensure strength and corrosion resistance. One angle bracket is used at each connection point between a rail and a post.

Installation of WPC Fence Angle Brackets

• Step 1: You need to place the angle bracket at the connection point between the rail and the post, ensuring correct positioning.

• Step 2: Use self-tapping screws to fix the angle bracket separately onto the rail and the post.

• Step 3: You need to use a level to ensure the rail connected via the angle bracket remains horizontal and aligned.

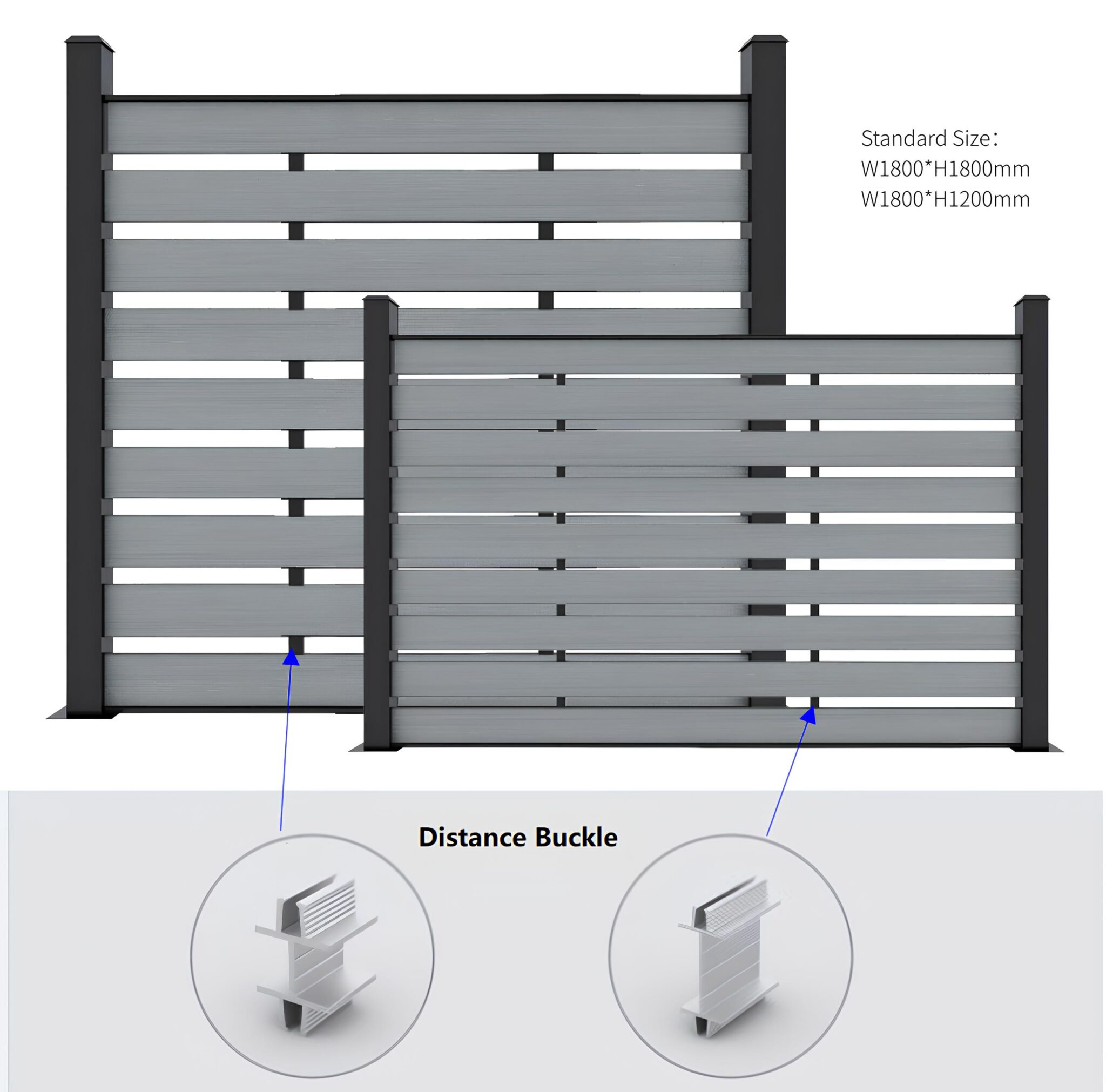

WPC Fence Distance Buckle

The WPC fence distance buckle is used for non-solid fences (fences with gaps between panels). Its core function is to ensure the distance between WPC fence panels remains consistent. It also prevents panels from wobbling, providing a more stable installation.

Distance buckles are usually made of aluminum alloy or stainless steel, designed to create precise, consistent gaps between two fence panels. These gaps are not only aesthetic but also allow for air circulation and thermal expansion/contraction, extending the fence’s lifespan.

Depending on design requirements and local climate conditions, distance buckles come in different heights to create gaps of varying widths.

WPC Fence Distance Buckle Usage Tips and Installation Points

• Quantity Calculation: Depends on various factors like post height, panel width, and desired panel gap; typically, two distance buckles are configured between two panels.

• Even Distribution: Ensure distance buckles are evenly distributed vertically to prevent fence panels from warping.

• Usually inserted during the fence panel installation process. For example, insert one fence panel, place the distance buckles, then insert the next fence panel.

• Ensure the distance buckle is correctly clicked or slotted into place to perform its intended fixing and spacing function.

WPC Fence Other Accessories

Besides the core accessories, various auxiliary accessories can enhance the functionality, aesthetics, and lifespan of a WPC fence. These accessories not only address specific installation needs but also allow customization of the fence’s final appearance and user experience based on personal preferences. Understanding these accessory options can help your WPC fence project achieve a professional standard.

WPC Fence Post Cap: Combining Aesthetics and Protection

The WPC fence post cap is not just a decorative element but also a crucial component for protecting the post from moisture ingress. Post caps come in various designs, from simple flat tops to decorative pyramid or ball tops, allowing you to choose a style that matches your fence. Post caps with integrated LED lighting offer both illumination and decoration, adding ambiance to your outdoor space at night.

The latest WPC post caps use UV-resistant materials to ensure they do not fade or become brittle after long-term sun exposure. Some high-end products also feature insect-repellent designs to prevent insects from nesting on top of the posts. Regardless of the style chosen, ensuring the post cap precisely matches the post dimensions is crucial.

WPC Fence Lighting System: Functionality and Atmosphere Creation

WPC fence lighting has evolved from simple utility to an important element of outdoor design, combining safety and aesthetics. Modern WPC fence lighting systems offer various choices, from post cap integrated lights to recessed LED strip lights, catering to different aesthetic and functional needs.

The most popular fence lighting trends for 2025 include solar-powered systems, smart control features, and low-energy LED technology. Good WPC fence lighting ideas can enhance the appearance of your fence and outdoor space, creating a pleasant atmosphere. Simultaneously, they can illuminate property boundaries, acting as a deterrent to potential intruders and protecting your personal safety.

There are various types of WPC fence lighting options you can choose from for DIY installation:

• Post cap lights: Installed on top of fence posts. Can be solar-powered or low-voltage LED lights. Provide downward or ambient light. This is the most common type.

• Surface/wall lights: Mounted on the vertical face of the post. Usually provide downward or directional light.

• Strip/linear lights: LED strips, often installed under the top or low rail, providing continuous indirect lighting.

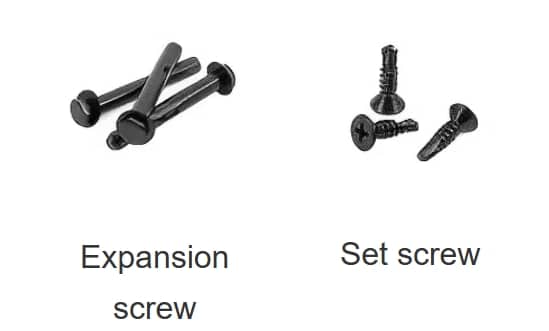

WPC Fence Screws: Seemingly Minor but Critically Important

Choosing the right screws might seem like a small detail, but it significantly impacts the durability and appearance of your WPC fence. Their core function is to secure all mechanical connections, such as the post base, angle brackets, and distance buckles. The post base requires expansion screws for fixing, while other components typically need set screws.

Color-matched decorative head screws are also available on the market, which are almost invisible after installation, maintaining the aesthetic integrity of the fence surface. It is highly recommended that you use Stainless Steel Screws, especially in outdoor environments, to prevent rust from affecting appearance and structural safety. The demand for screws is high, so it’s advisable to purchase extras as spares.

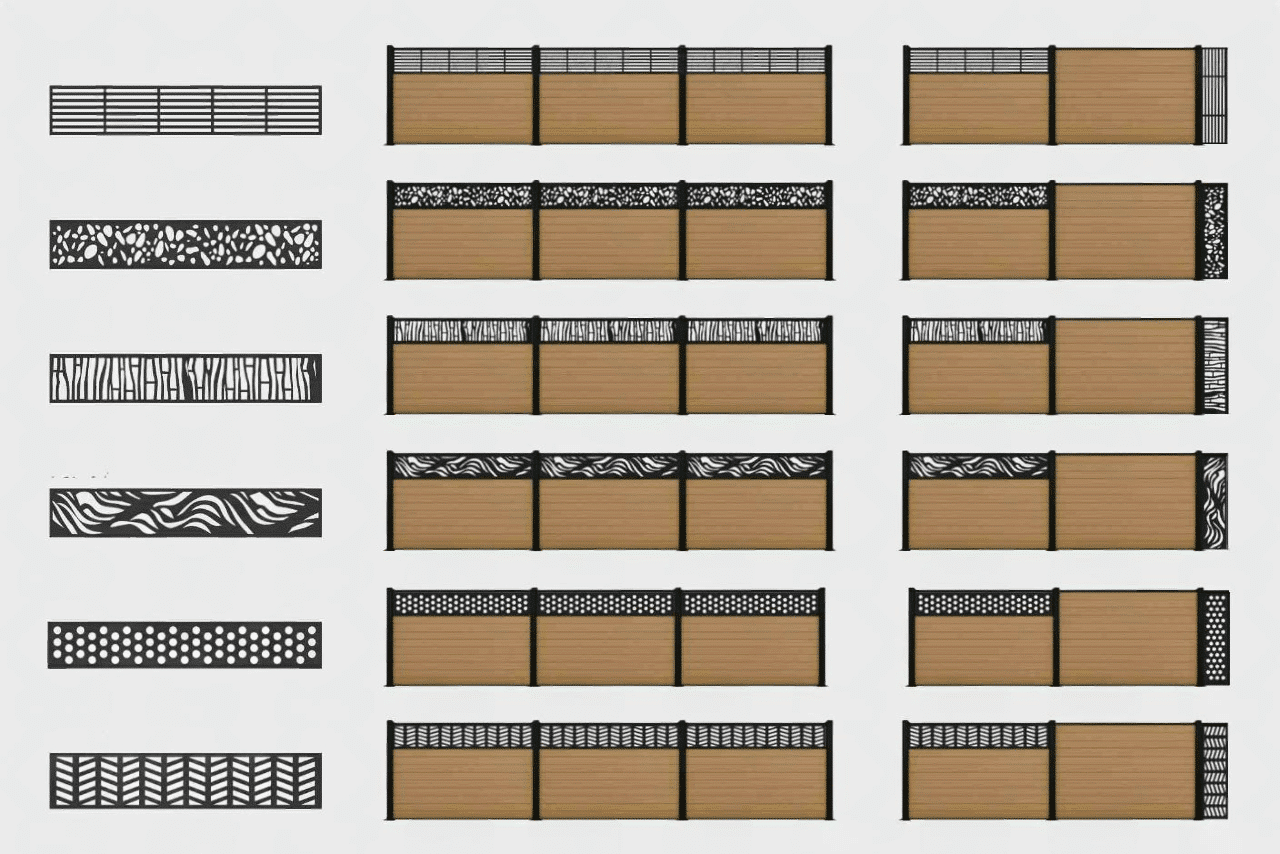

WPC Fence Decorative Elements: Personalize Your Fence

Decorative elements can transform a standard WPC fence into a unique design statement, showcasing personal taste. From simple decorative infill panels to lattice designs, finials, and artistic panels, various decorative accessories allow you to customize the fence’s appearance according to your preferences.

In recent years, modular decorative elements have become increasingly popular, allowing homeowners to easily change or update the fence’s look at any time without replacing the entire system. These elements are usually designed for easy installation, manageable even for DIY enthusiasts.

Designer’s Advice: Don’t overuse decorative elements. Strategically applying decorative accessories in key locations, such as entrances or focal points, is often more effective than using them throughout the entire fence. This approach saves costs while creating a more impactful design.

Latest WPC Fence Accessories Developments and Trends for 2025

Multifunctional Demand: Consumer demand for versatility is driving manufacturers to develop innovative accessories with integrated extra features, such as smart lighting, security monitoring, and even wireless charging stations.

Smart Integrated Systems: Fence accessories equipped with sensors and connectivity can integrate with smart home systems, providing security monitoring and environmental data collection capabilities.

Modular Design: A new generation of fully customizable modular WPC fence systems allows homeowners to easily add, remove, or reconfigure fence components based on their needs.

Frequently Asked Questions

1: Do WPC fence accessories require special maintenance?

WPC fence accessories generally require no maintenance. For accessories made of WPC material, regular cleaning with mild soap and water is sufficient to maintain their appearance.

2: Can WPC fence accessories withstand extreme weather conditions?

High-quality WPC fence accessories are designed to withstand various weather conditions, including high temperatures, severe cold, strong winds, and high humidity. However, in regions with extreme climates, reinforced accessories specifically designed for that environment should be chosen.

3: How do I determine how many WPC fence accessories I need?

Calculating the required number of accessories depends on the fence length, height, and design. A general rule is that post spacing is 6-8ft, and each fence section requires at least two rails. The specific quantity should be determined based on manufacturer recommendations and local building codes. Preparing an extra 5-10% of accessories as spares is a wise precaution.

4: Can I mix and match WPC fence accessories from different brands?

While technically possible, it is not recommended to mix accessories from different brands, as there may be discrepancies in dimensions, connection methods, and color matching.

Conclusion

After reading the above content, you should now have a basic understanding of WPC fence accessories and feel more prepared when starting your yard’s WPC fence project. It’s worth noting that WPC fence accessories can be purchased at local hardware stores, or they can be supplied as a complete set by the manufacturer when you buy the WPC fence panels. I recommend the latter option, as it will provide significant convenience for the installation, after-sales service, and maintenance of your fence later on.

As a WPC fence manufacturer with over twenty years of experience, ecoxplank offers a full range of products, including WPC fence panels and all necessary WPC fence accessories. We welcome your inquiries.

More resourse

galvanized steel—————————WIKIPEDIA

aluminum alloy—————————–WIKIPEDIA

Corrosion Resistance———————–WBDG

UV-resistant materials ——————–WEVOLVER

Good WPC fence lighting ideas————–ECOXPLANK

expansion screws—————————STRUCTURAL ENGINEERING

ecoxplank———————————–https://ecoxplank.com

WPC fence panels and all necessary

WPC fence accessories———————ECOXPLANK

3 thoughts on “Master All WPC Fence Accessories in 5 Minutes”

92pakgameapp is pretty cool. I like the selection of Pakistani games they have. Simple to install and fun to play. Check it out for yourself: 92pakgameapp

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Just checked out bharatsportsmumabi, and wow, it’s got a ton of sports info. Easy to navigate too. Check out bharatsportsmumabi if you’re a sports fan!

Comments are closed.